Are you tired of inefficient bagging processes that are slowing down your productivity and costing you money? Look no further than FFS (Form-Fill-Seal) technology, which is revolutionizing the way companies handle their bagging needs. In this article, we will explore why FFS is unbeatable when it comes to productivity and commercial efficiency, and how it outperforms traditional bagging machines.

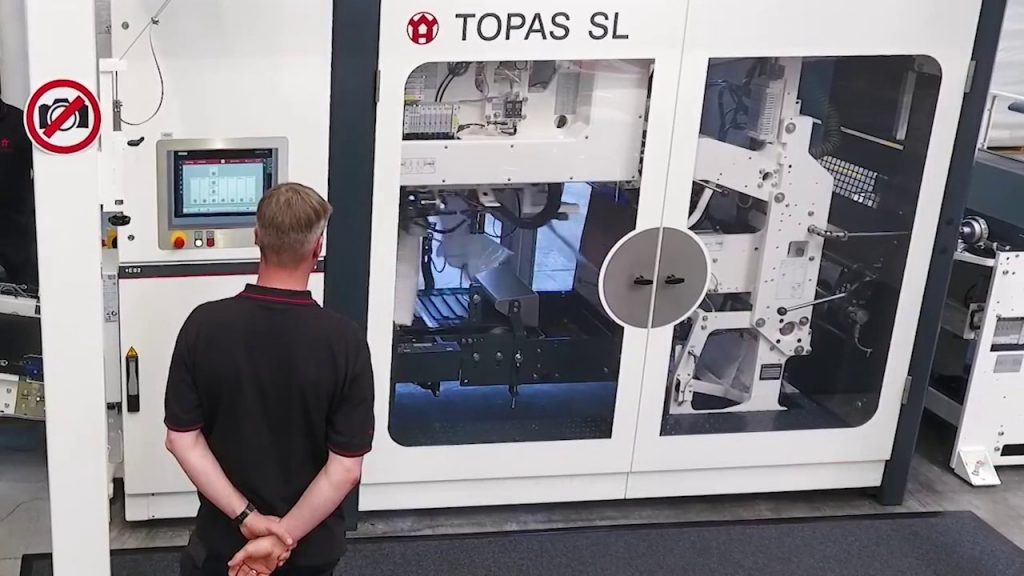

FFS is not just an isolated bagging solution; it is a comprehensive system that streamlines the entire packaging process. With traditional bagging machines, you often need multiple machines to complete different stages of the packaging process, such as filling, sealing, and labeling. This not only takes up valuable space but also increases the chances of errors and downtime.

In contrast, FFS combines all these functions into a single, integrated system. The bag is formed, filled, and sealed in one continuous process, eliminating the need for multiple machines and reducing the risk of errors. This results in a much more efficient and streamlined operation, saving you time, money, and resources.

One of the key advantages of FFS is its speed. Traditional bagging machines can only handle a limited number of bags per minute, which can be a major bottleneck in high-volume production environments. FFS, on the other hand, can achieve much higher speeds, allowing you to significantly increase your output without compromising on quality.

Another advantage of FFS is its versatility. It can handle a wide range of bag sizes and types, from small sachets to large sacks. This flexibility is particularly useful for companies that deal with multiple products or frequently change their packaging requirements. With FFS, you can easily adapt to changing demands without having to invest in new equipment.

FFS also offers superior product protection. The bags produced by FFS are tightly sealed, preventing moisture, contaminants, and tampering from compromising the quality and integrity of your products. This is especially important for industries such as food, pharmaceuticals, and chemicals, where product safety and hygiene are critical.

Furthermore, FFS is designed with efficiency in mind. It minimizes material waste by using precisely measured film lengths and optimizing the use of packaging materials. This not only helps reduce costs but also minimizes the environmental impact of your packaging operations.

In summary, FFS is a game-changer when it comes to productivity and commercial efficiency. Its integrated system, high speed, versatility, product protection, and efficiency make it the ideal choice for companies looking to optimize their bagging processes. Say goodbye to outdated bagging machines and embrace the future of packaging technology with FFS.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Bagging Machine

"Efficient Bagging System: Streamlining Product Silo to Pallet with FFS Technology"