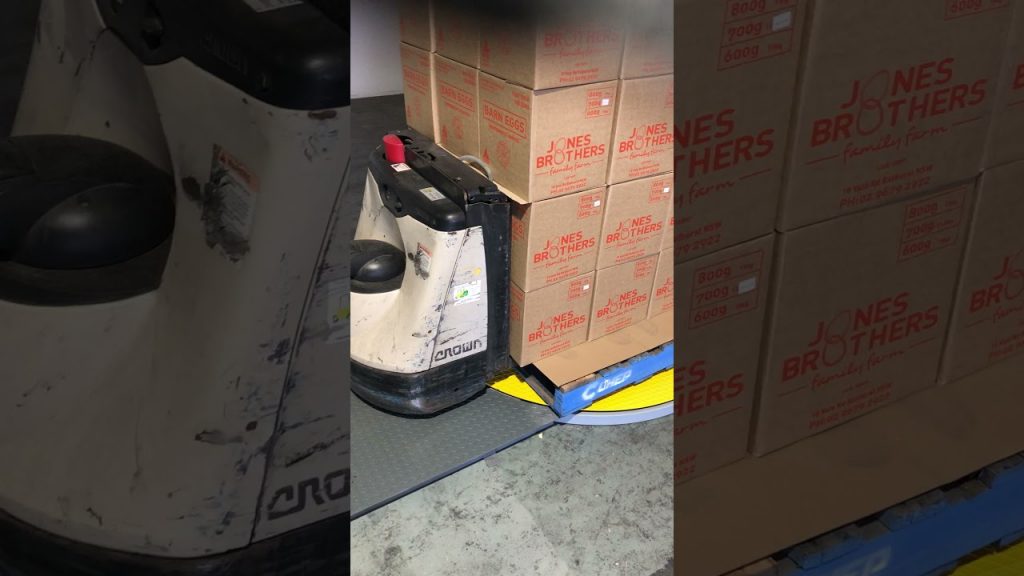

Easy, Safe, and Quick Pallet Wrapping Using a Manual Pallet Jack on a Custom Made Ramp

Introduction:

In today's fast-paced world, businesses are constantly seeking ways to enhance their productivity and efficiency. When it comes to warehouse operations, one crucial aspect is pallet wrapping. The process of securing goods onto pallets ensures safe transportation and storage. To streamline this process, many companies are turning to innovative solutions like the MAS350 Pallet Wrapping Machine, combined with a manual pallet jack on a custom-made ramp. In this article, we will explore the benefits of this system and how it simplifies pallet wrapping.

Easy and Efficient Wrapping Process:

Traditionally, pallet wrapping can be a time-consuming and physically demanding task. However, with the MAS350 Pallet Wrapping Machine, the process becomes incredibly easy and efficient. This machine automates the wrapping process, eliminating the need for manual labor and reducing the time required. By simply placing the pallet onto the ramp, using a manual pallet jack, and activating the machine, you can achieve a professional and secure wrap in no time.

Enhanced Safety Measures:

Worker safety is a top priority for any business. The combination of a manual pallet jack and a custom-made ramp ensures a safe environment for pallet wrapping. The ramp provides a smooth and stable surface for the pallet jack, minimizing the risk of accidents or injuries. Additionally, the MAS350 Pallet Wrapping Machine eliminates the need for workers to manually stretch and bend, reducing the strain on their bodies. This combination of safety measures not only protects workers but also improves overall productivity.

Quick and Consistent Results:

Time is of the essence in any warehouse setting. The MAS350 Pallet Wrapping Machine, in conjunction with a manual pallet jack and custom-made ramp, delivers quick and consistent results. The machine's advanced technology ensures a tight and secure wrap that keeps the goods in place during transportation. With its adjustable settings, you can customize the wrapping tension according to your specific requirements. This consistency in wrapping quality saves time and enhances the overall efficiency of your operations.

Cost-effective Solution:

Investing in a Pallet Wrap Machine for Sale, like the MAS350, is a cost-effective solution for businesses. By automating the pallet wrapping process, you reduce the need for additional labor, ultimately saving on manpower costs. Moreover, the consistent and secure wrapping provided by the machine minimizes the risk of product damage during transit. This translates to fewer returns or losses, further enhancing your bottom line. The long-term cost savings and improved efficiency make this solution an excellent investment for any warehouse.

Conclusion:

When it comes to pallet wrapping, efficiency and safety are paramount. The combination of a manual pallet jack on a custom-made ramp, along with the MAS350 Pallet Wrapping Machine, offers an easy, safe, and quick solution. This innovative system streamlines the pallet wrapping process, enhances worker safety, delivers consistent results, and ultimately saves costs. As businesses strive for greater productivity, embracing advanced solutions like this becomes imperative.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert URL or contact information of the manufacturer here] Pallet Wrapping Machine

"Efficient Pallet Wrapping Solution: Custom Ramp Access & E Wrap System - Available for Purchase"