Check out the leading manufacturer for professional coil packing solutions here:

As a sales engineer in the packaging industry, I have witnessed firsthand the impact that advanced machinery has on improving efficiency and productivity in manufacturing plants. One such machine that has revolutionized the packaging process is the Used Shrinking Machine. In this article, we will explore the benefits of using a Used Shrinking Machine in a beverage bottling plant and its role in the film shrink wrapping process.

The beverage industry is a highly competitive market, with companies constantly seeking ways to differentiate their products and streamline their operations. One area where efficiency plays a crucial role is in the packaging process. The Used Shrinking Machine has emerged as a game-changer in this regard, offering significant advantages over traditional packaging methods.

Used Shrinking Machines are designed to wrap products in a protective film, which is then heated to shrink and conform tightly to the shape of the product. This process not only provides a secure and tamper-evident packaging solution but also enhances the visual appeal of the product on store shelves. The tight and sleek packaging helps to attract customers and creates a positive impression of the brand.

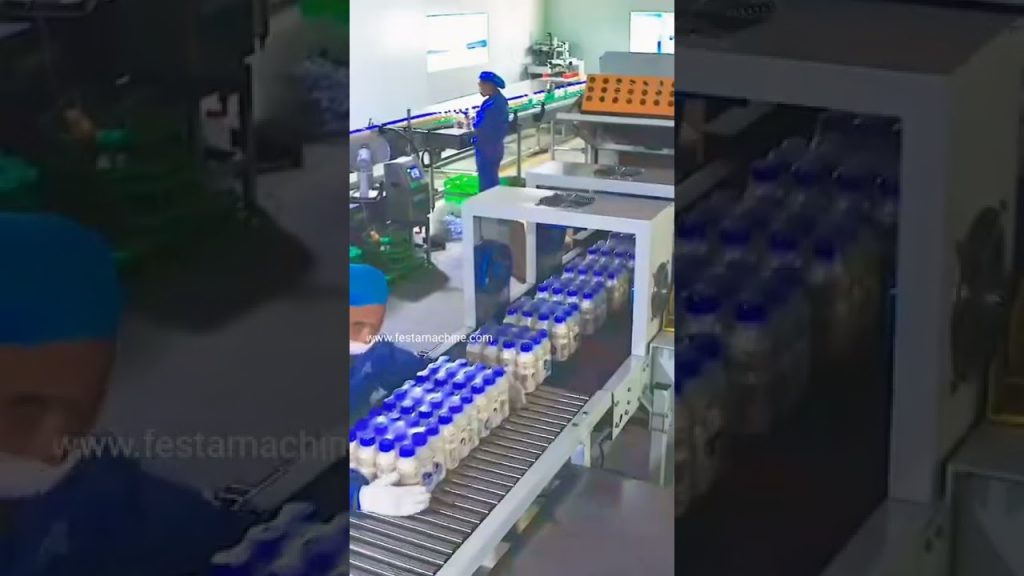

In a beverage bottling plant, the Used Shrinking Machine plays a vital role in the packaging of bottles. By using a shrink wrapping machine, bottles can be wrapped individually or in groups, depending on the packaging requirements. This flexibility allows manufacturers to cater to different customer preferences and market demands.

The film shrink wrapping process offers several benefits for beverage bottling plants. Firstly, it provides excellent protection against external elements such as dust, moisture, and tampering. This ensures that the product reaches the consumer in pristine condition, enhancing customer satisfaction and brand reputation.

Secondly, the film shrink wrapping process is highly efficient and cost-effective. With the automation provided by Used Shrinking Machines, the packaging process can be streamlined, reducing labor costs and improving overall productivity. These machines are capable of handling high volumes of bottles in a short amount of time, making them an ideal solution for beverage bottling plants.

Furthermore, the film used in shrink wrapping is lightweight and requires minimal storage space compared to traditional packaging materials such as cardboard boxes. This not only saves on storage costs but also reduces the environmental impact of packaging waste.

When considering the purchase of a Used Shrinking Machine, it is important to choose a reliable and reputable manufacturer. Look for a company that has a proven track record in providing high-quality packaging solutions and excellent customer support. It is also essential to consider the specific requirements of your beverage bottling plant and choose a machine that aligns with your production needs.

In conclusion, the Used Shrinking Machine has become an indispensable tool for beverage bottling plants in the film shrink wrapping process. Its ability to provide secure and visually appealing packaging, along with its efficiency and cost-effectiveness, make it an ideal choice for manufacturers in the beverage industry. By investing in a reliable Used Shrinking Machine, companies can enhance their packaging process and gain a competitive edge in the market.

Check out the leading manufacturer for professional coil packing solutions here: Shrinking Machine

"Optimizing Beverage Packaging Efficiency: Exploring Shrink Wrapping Machines for Bottling Plants, Including Used Options"