Title: Efficient Handling Machine Manufacturers - Boost Your Production Line with Galvanized Rollers Conveyor for Clean Machine Material Handling

Description:

Introduction:

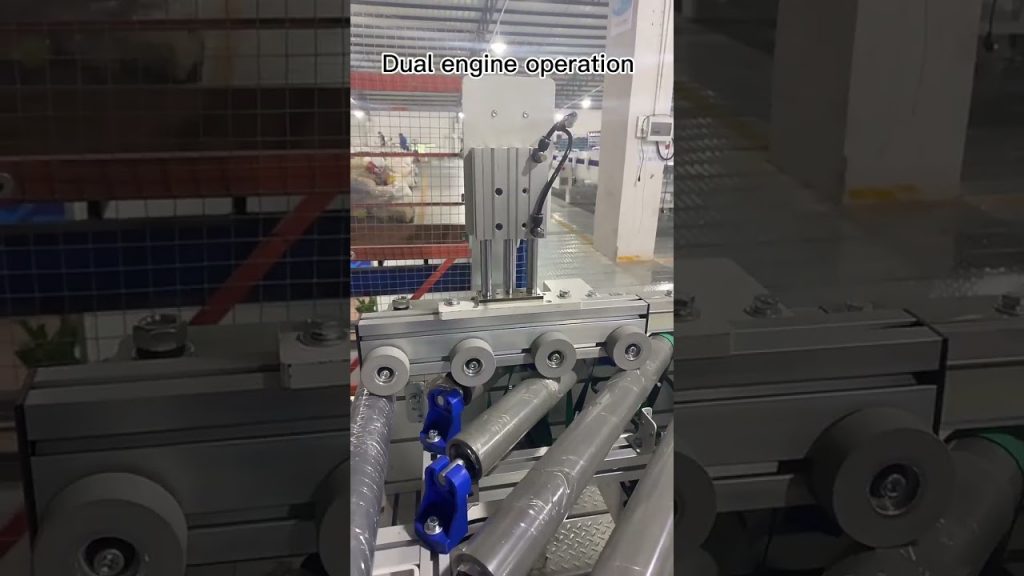

Welcome to our video presentation focused on handling machine manufacturers and the revolutionary rolling assembly production line. In this video, we will delve into the world of galvanized rollers conveyors, designed specifically for clean machine material handling. With detailed insights and informative content, we aim to provide you with a comprehensive overview of this cutting-edge technology and its benefits.

Video Content:

At our handling machine manufacturing facility, we prioritize efficiency and productivity. Our rolling assembly production line is revolutionizing the industry by streamlining material handling processes. With the incorporation of galvanized rollers conveyors, we ensure a clean and seamless transfer of materials, enhancing the overall workflow and reducing downtime.

Key Highlights:

1. Galvanized Rollers Conveyor: Our state-of-the-art galvanized rollers conveyors are meticulously designed to withstand heavy loads, ensuring durability and longevity. These conveyors offer smooth, reliable, and efficient material handling, reducing manual labor requirements and increasing overall productivity.

2. Clean Machine Material Handling: With a focus on cleanliness and hygiene, our conveyors are designed to meet the highest standards of cleanliness in material handling. The galvanized rollers prevent contamination and ensure a sanitized environment, making them ideal for industries such as food processing, pharmaceuticals, and electronics.

3. Rolling Assembly Production Line: Our rolling assembly production line is engineered to optimize efficiency and minimize production time. By seamlessly integrating the galvanized rollers conveyors, we enhance the overall workflow, reducing bottlenecks and increasing throughput.

Operation Steps:

1. Material Loading: The first step in the process is loading the materials onto the galvanized rollers conveyor. The sturdy construction of the conveyor ensures safe and efficient loading, minimizing the risk of damage or accidents.

2. Automated Transfer: Once the materials are loaded, the conveyor system automatically transports them along the production line. The galvanized rollers provide a smooth and consistent movement, ensuring the materials reach their designated stations accurately.

3. Assembly and Inspection: At each station, the necessary assembly tasks are performed, followed by meticulous inspection to maintain quality control standards. The galvanized rollers conveyor facilitates a steady flow of materials, eliminating delays and maximizing productivity.

4. Final Output: After completing the assembly and inspection process, the finished products are conveyed to the final output area. The galvanized rollers conveyor ensures a seamless transition, reducing the risk of damage and maintaining the overall quality of the products.

Call to Action:

If you're looking to optimize your production line and enhance material handling efficiency, our handling machine manufacturers can provide you with the cutting-edge rolling assembly production line and galvanized rollers conveyors. Don't forget to subscribe to our channel, like this video, and share it with others who may benefit from this valuable information.

Additional Tags and Keywords:

handling machine manufacturers, rolling assembly production line, galvanized rollers conveyor, clean machine material handling, material handling efficiency, optimized production line, increased productivity, seamless material transfer, industrial automation, innovative technology.

Hashtags:

#handlingmachinemanufacturers #productionline #galvanizedrollersconveyor #cleanmachinehandling #efficiency #materialhandling #automation

Title: Enhanced Efficiency and Precision: Galvanized Roller Conveyor for Clean Machine Material Handling

Introduction:

In today's fast-paced industrial landscape, maximizing efficiency and ensuring a clean production environment are crucial for businesses. Our Rolling Assembly Production Line introduces a groundbreaking solution – the Galvanized Roller Conveyor. Designed to handle clean machine materials with utmost precision and reliability, this innovative system revolutionizes material handling processes, ultimately boosting productivity and reducing downtime.

Section 1: Superior Galvanized Rollers for Unmatched Durability

1.1 Unparalleled Corrosion Resistance: Our Galvanized Rollers undergo a state-of-the-art galvanization process, providing exceptional protection against corrosion, ensuring long-lasting performance even in harsh environments.

1.2 Reinforced Load Capacity: The rollers are engineered with reinforced cores, capable of handling heavy loads with ease, maximizing productivity and minimizing equipment wear and tear.

1.3 Smooth Operation and Low Maintenance: The precisely machined and balanced rollers guarantee smooth movement, reducing friction and the need for frequent maintenance, resulting in higher operational efficiency.

Section 2: Advanced Conveyor Technology for Optimal Material Handling

2.1 Customized Line Configurations: Our Galvanized Roller Conveyor system offers a flexible design, allowing customization to meet the specific requirements of any production line.

2.2 Precision Alignment and Tracking: The conveyor's advanced tracking mechanism ensures accurate alignment of materials, eliminating jams and interruptions, thereby enhancing overall production efficiency.

2.3 Seamless Integration: Our Galvanized Roller Conveyor seamlessly integrates with existing machinery and automated systems, enabling a streamlined production process without costly modifications.

Section 3: Hygienic Design for Clean Machine Material Handling

3.1 Contamination Prevention: The Galvanized Roller Conveyor is designed to meet the highest cleanliness standards, making it ideal for industries with stringent hygiene requirements such as food processing, pharmaceuticals, and electronics.

3.2 Easy Cleaning and Maintenance: The conveyor's smooth surfaces and accessible components simplify cleaning procedures, reducing downtime and ensuring optimal cleanliness at all times.

3.3 Modular Components for Versatile Applications: The conveyor system's modular design allows for easy customization and integration of additional features, such as inspection stations, sorting mechanisms, and more.

Conclusion:

With our Galvanized Roller Conveyor, Rolling Assembly Production Line presents an innovative solution for clean machine material handling. By combining superior galvanized rollers, advanced conveyor technology, and a hygienic design, this system enhances efficiency, precision, and cleanliness in material handling operations. Experience the future of industrial production with our Galvanized Roller Conveyor – the key to unlocking enhanced productivity and cost-effectiveness in your manufacturing processes.Handling Machine

#Rolling #Assembly #Production #Line #Galvanized #Rollers #Conveyor #Clean #Machine #Material #Handling