Heat Shrinking Machine - The Ultimate Solution for Efficient Packaging

Introduction:

In today's fast-paced world, efficient packaging plays a crucial role in ensuring the safe transportation and delivery of goods. Among the various packaging techniques available, heat shrinking is widely recognized for its effectiveness and reliability. In this article, we will explore the benefits and applications of heat shrinking machines, specifically focusing on the JCW-HSB20 Heat Shrinking Machine by JCWELEC.

What is a Heat Shrinking Machine?

A heat shrinking machine is a specialized device used to apply heat to a heat shrinkable tubing, which then shrinks tightly around the object it is covering. This process creates a secure and protective barrier around the product, safeguarding it from damage during transit. Heat shrinking machines are widely used across various industries, including electronics, automotive, food and beverage, and pharmaceuticals.

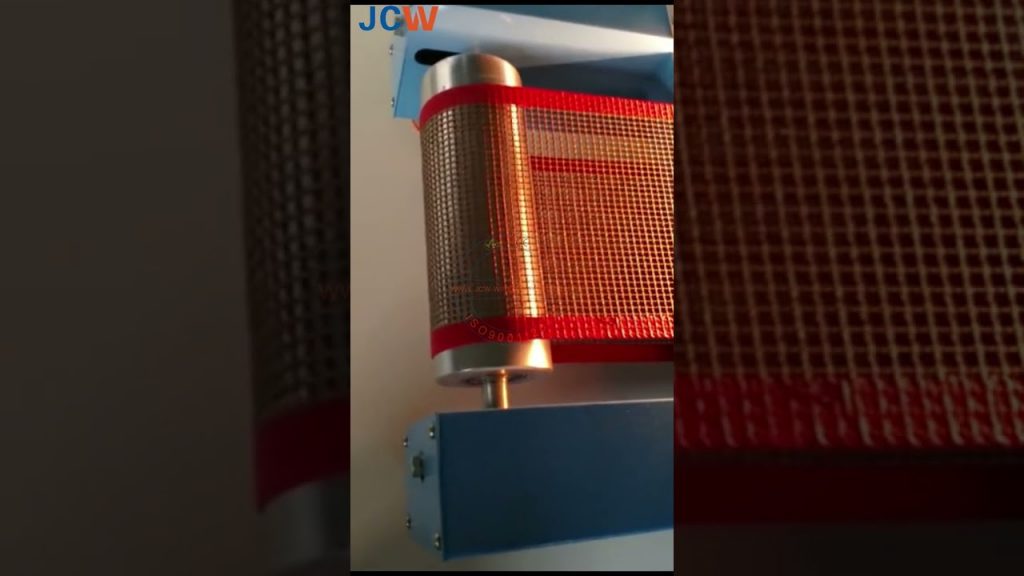

The JCW-HSB20 Heat Shrinking Machine:

The JCW-HSB20 Heat Shrinking Machine offered by JCWELEC is a cutting-edge solution that provides exceptional performance and reliability. This state-of-the-art machine is designed to streamline the packaging process, ensuring efficiency and cost-effectiveness.

Key Features of the JCW-HSB20 Heat Shrinking Machine:

1. Advanced Technology: The JCW-HSB20 incorporates the latest heat shrinking technology, enabling precise and consistent shrinkage every time. This ensures a snug fit and optimal protection for the packaged product.

2. Versatility: This machine is compatible with a wide range of heat shrinkable tubing, making it suitable for various applications. Whether you need to package small components or larger objects, the JCW-HSB20 can handle it all.

3. User-Friendly Interface: The JCW-HSB20 features an intuitive user interface, allowing operators to easily control and adjust the machine settings. This user-friendly design reduces the learning curve and increases productivity.

4. High-Speed Operation: With its high-speed operation, the JCW-HSB20 can efficiently process a large volume of products in a short amount of time. This makes it an ideal choice for businesses with high packaging demands.

Applications of Heat Shrinking Machines:

1. Electronics: Heat shrinking machines are widely used in the electronics industry to protect delicate components during shipment. The heat shrinkable tubing provides insulation and prevents moisture or dust from damaging the electronic devices.

2. Automotive: Heat shrinking machines are essential in the automotive industry for harnessing and protecting wiring, ensuring reliable electrical connections. The heat shrinkable tubing provides resistance against vibrations, abrasions, and environmental factors.

3. Food and Beverage: Heat shrinking machines play a crucial role in the food and beverage industry for packaging products securely. The heat shrinkable tubing provides a tamper-evident seal, preserving the freshness and quality of the packaged goods.

4. Pharmaceuticals: Heat shrinking machines are utilized in the pharmaceutical industry to package medicines and medical devices. The heat shrinkable tubing provides a sterile and protective barrier, ensuring the integrity of the products.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

In conclusion, heat shrinking machines are a game-changer in the packaging industry, offering efficient and reliable protection for various products. The JCW-HSB20 Heat Shrinking Machine by JCWELEC exemplifies the advancements in this field, providing exceptional performance and versatility. Whether you are in the electronics, automotive, food and beverage, or pharmaceutical industry, investing in a heat shrinking machine can significantly enhance your packaging process. So, why wait? Upgrade your packaging operations with the JCW-HSB20 Heat Shrinking Machine and experience the benefits firsthand. Shrinking Machine

"Efficient Heat Shrinkable Tubing Processing and Tube Shrinking Machine: A Comprehensive Overview"