Title: Orbital Stretch Wrapper | WRWA-200 Horizontal Stretch Wrapper with Bunk Inserter

Description:

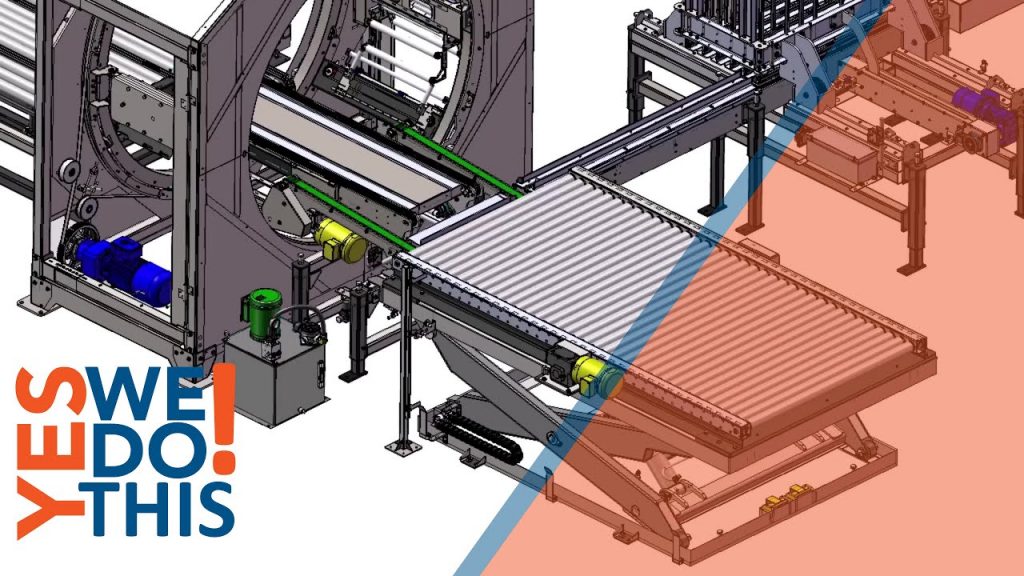

H1: Orbital Stretch Wrapper | WRWA-200 Horizontal Stretch Wrapper with Bunk Inserter

H2: Efficient and Reliable Stretch Wrapping Solution for Your Packaging Needs

H3: Watch our video to discover the features and benefits of the WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter.

Introduction:

Welcome to our video showcasing the advanced capabilities and exceptional performance of the WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter. This state-of-the-art orbital stretch wrapper is designed to revolutionize your packaging process by providing efficiency, reliability, and exceptional results.

Video Content:

In this video, we will delve into the key points and highlights of the WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter. Let's explore the features that make this machine an ideal choice for your packaging requirements.

H4: Superior Stretch Wrapping Technology

Our WRWA-200 Horizontal Stretch Wrapper utilizes advanced technology to ensure precise and secure wrapping of your products. With its orbital design, this machine offers consistent stretch wrapping, preventing any damage or shifting during transportation.

H4: Bunk Inserter for Enhanced Efficiency

The WRWA-200 comes equipped with a bunk inserter, allowing for seamless integration into your packaging line. This feature enables the automatic insertion of bunks, enhancing productivity and reducing manual labor.

H4: Easy Operation and Customization

The WRWA-200 boasts a user-friendly interface, making it simple for operators to set up and control the wrapping process. Additionally, this machine offers customizable settings, allowing you to tailor the wrapping parameters according to your specific needs.

H4: Versatile and Reliable Performance

Whether you need to wrap different-sized products, irregular shapes, or heavy loads, the WRWA-200 can handle it all. Its robust construction and reliable performance ensure that your products are securely wrapped for safe transportation.

Call to Action:

Subscribe to our channel to stay updated on the latest packaging solutions and techniques. Don't forget to hit the like button if you found this video informative. Share this video with your colleagues who might benefit from the WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter.

Additional Tags and Keywords:

Stretch wrapper, horizontal stretch wrapper, orbital stretch wrapper, WRWA-200, bunk inserter, packaging solution, efficient stretch wrapping, reliable performance, user-friendly interface, customizable settings, versatile performance, secure transportation.

Hashtags:

#StretchWrapper #HorizontalStretchWrapper #OrbitalStretchWrapper #WRWA200 #BunkInserter #PackagingSolution #EfficientWrapping #ReliablePerformance #SecureTransportation

Here's a sample tilter for the WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter:

Title: WRWA-200 Horizontal Stretch Wrapper with Bunk Inserter Tilter

Introduction:

The WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter is a versatile machine that provides efficient and reliable horizontal stretch wrapping and bunk inserting capabilities. This tilter guide aims to provide step-by-step instructions on how to operate the tilter function of the WRWA-200, ensuring optimum performance and safety.

Procedure:

1. Preparing the Machine:

a. Ensure that the WRWA-200 is properly installed and connected to a power source.

b. Verify that the machine is in a stable position and all safety guards are in place.

c. Make sure the bunk inserter is properly aligned and ready for operation.

2. Loading the Product:

a. Position the product to be tilted on the conveyor belt in front of the bunk inserter.

b. Ensure that the product is stable, balanced, and within the weight and size limits specified by the machine's manual.

3. Initiating the Tilter Function:

a. Select the tilter mode on the control panel of the WRWA-200.

b. Adjust the tilter settings, such as the angle and speed, according to the specific requirements of the product being tilted.

c. Activate the tilter function by pressing the designated start button.

4. Tilt Process:

a. The WRWA-200 will commence the tilting process, gradually adjusting the angle of the product.

b. Monitor the tilting operation closely to ensure that the product remains stable and secure throughout the process.

c. Make any necessary adjustments to the tilter settings during the operation, if required, to achieve the desired tilt angle.

5. Completing the Tilt:

a. Once the desired tilt angle is reached, the WRWA-200 will automatically stop the tilting process.

b. Verify that the product is safely tilted and positioned according to the desired configuration.

c. If further adjustments are necessary, utilize the manual override controls to fine-tune the tilt angle.

6. Unloading the Tilted Product:

a. Once the tilting process is completed, the product can be unloaded from the conveyor belt or further processed as required.

b. Follow appropriate safety procedures when unloading the product to prevent any accidents or injuries.

Conclusion:

The WRWA-200 Horizontal Stretch Wrapper with a Bunk Inserter offers a reliable and efficient tilter function for tilting products to desired angles. By following this tilter guide, operators can ensure safe and effective operation, achieving optimal results for their specific application. Always refer to the machine's manual for detailed instructions and safety guidelines.Orbital Stretch Wrapper

#WRWA200 #Horizontal #Stretch #Wrapper #Bunk #Inserter