In this YouTube video article, we will explore the world of paper plate machines and the various components that make up a full production line. We will also discuss the importance of paper packing machines and their role in the manufacturing process. So, let's dive in and discover more about this fascinating industry!

Introduction:

Paper plate machines have revolutionized the production of disposable paper plates, making it easier and more efficient for manufacturers to meet the growing demand. These machines are designed to automate the entire process, from cutting the paper sheets to molding them into the desired shape.

The Full Production Line:

A complete paper plate machine production line consists of multiple machines working together seamlessly. The first machine in the line is the paper plate making machine, which cuts the paper sheets into the desired shape and size. This machine uses advanced technology to ensure precise cutting and minimize wastage.

Once the paper plates are cut, they move on to the molding machine. This machine uses heat and pressure to mold the paper sheets into the shape of a plate. The plates are then cooled and stacked, ready for the next stage of the production line.

The paper tray machine is another crucial component of the production line. This machine is responsible for shaping the paper into trays, which are widely used in the food industry for packaging purposes. The trays are designed to be sturdy and leak-proof, ensuring the safety of the products they hold.

The final step in the production line is the paper lunch box making machine. This machine specializes in creating paper lunch boxes, which are commonly used for take-out meals. These machines are capable of producing a large volume of lunch boxes in a short period, making them essential for businesses in the food industry.

The Importance of Paper Packing Machines:

Paper packing machines play a vital role in the production of paper plates, trays, and lunch boxes. These machines are responsible for efficiently packaging the finished products, ensuring their protection during transportation and storage.

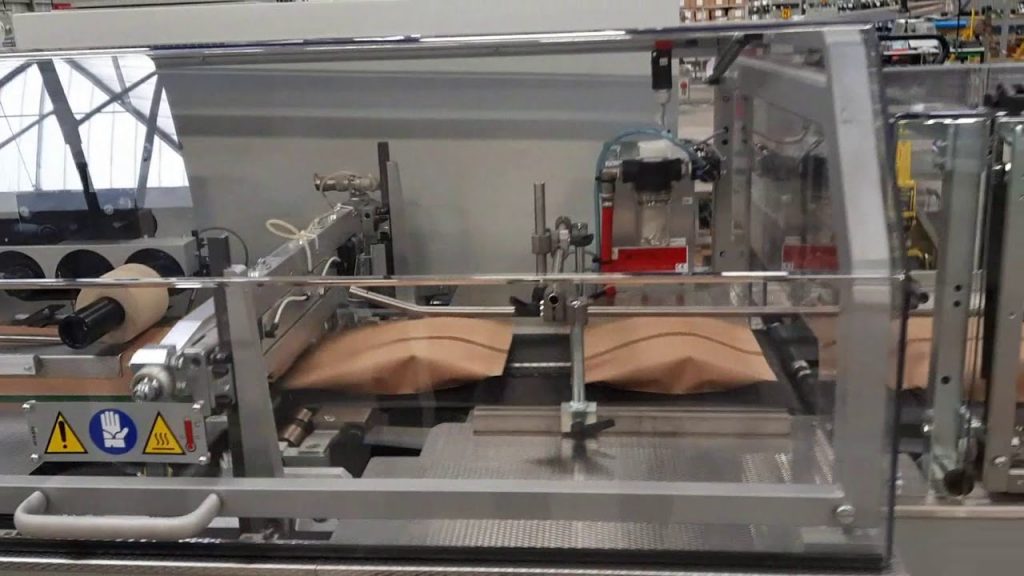

One popular type of paper packing machine is the paper shrink packing machine. This machine uses heat to shrink a plastic film around the paper plates or trays, creating a tight and secure package. The shrink film not only protects the products from dust, dirt, and moisture but also enhances their overall presentation.

Paper Packing Machine Manufacturers:

When it comes to sourcing paper packing machines, it is essential to partner with reliable manufacturers. India is home to several leading manufacturers of paper packing machines, including those specializing in duplex board paper plate making machines.

These manufacturers offer a wide range of machines, including complete production lines with paper shrink packing machines. Their machines are known for their durability, efficiency, and advanced technology, ensuring high-quality packaging solutions for businesses in various industries.

Conclusion:

In conclusion, paper plate machines and paper packing machines are revolutionizing the manufacturing industry. With the help of these machines, businesses can streamline their production process and meet the growing demand for disposable paper plates, trays, and lunch boxes.

If you're looking for a professional solution to your coil packing needs, look no further than the leading manufacturers in the industry. They offer a wide range of paper packing machines, including those specifically designed for paper plates, trays, and lunch boxes. With their expertise and cutting-edge technology, you can ensure efficient and reliable packaging for your products. Paper Packing Machine

"DUPLEX BOARD Paper Plate and Paper Shrink Packaging Machine Full Line - Top Manufacturers in India"