Title: Automate Your Contact Plug Production with the Advanced Automatic Handling Machine

Description:

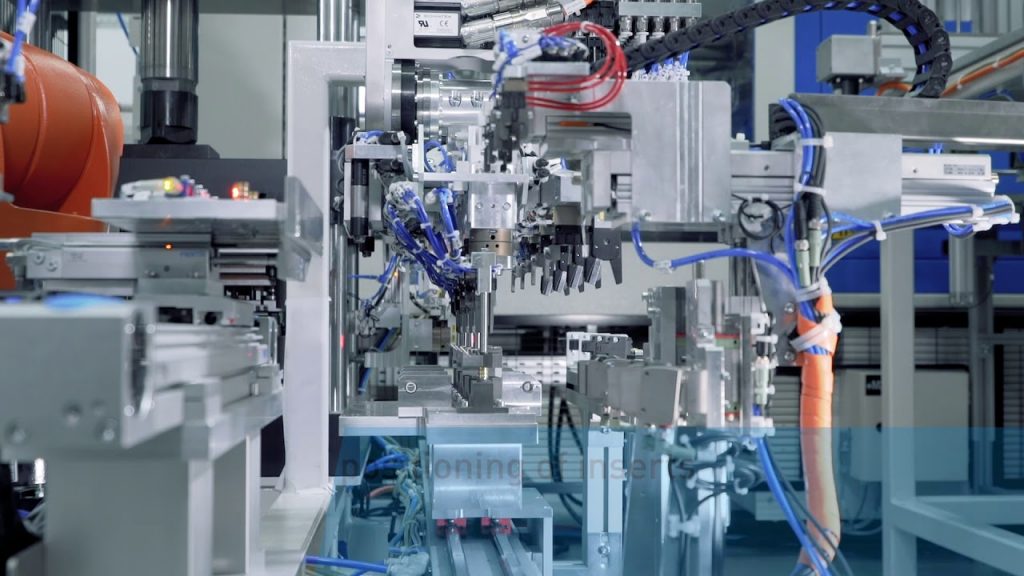

Welcome to our informative video showcasing the incredible capabilities of the Automatic Handling Machine. In this video, we will take you through the process of automatic injection molding of contact plugs, featuring automatic handling of 4 x 4 inserts. Additionally, we will explore the fully automatic production of contact plugs in a 4 cavity mold. Each contact plug includes 1 assembly plate, 2 bushings, and much more.

Introduction:

Discover the revolutionary Automatic Handling Machine that is revolutionizing the contact plug production industry. With its cutting-edge technology and advanced features, this machine streamlines the entire manufacturing process, increasing efficiency and productivity.

Video Content:

In this video, we will delve into the key points and operation steps involved in the automatic handling and injection molding of contact plugs. Experience the seamless integration of 4 x 4 inserts, allowing for a swift and precise production process. Witness firsthand how this machine ensures consistent quality and accuracy in every contact plug manufactured.

Highlights:

- Efficient automatic handling of 4 x 4 inserts for seamless production

- Advanced injection molding process for contact plugs

- Fully automatic production in a 4 cavity mold

- Each contact plug features 1 assembly plate and 2 bushings

- Streamlined process for increased productivity and efficiency

Call to Action:

If you found this video informative and insightful, we encourage you to like, subscribe, and share it with others who may benefit from learning about the Automatic Handling Machine. Don't forget to hit the notification bell to stay updated on our future videos.

Additional Tags and Keywords:

Automatic Handling Machine, automatic injection molding, contact plugs, 4 x 4 inserts, fully automatic production, 4 cavity mold, assembly plate, bushings, manufacturing process, efficiency, productivity, advanced technology.

Hashtags:

#AutomaticHandlingMachine #InjectionMolding #ContactPlugs #ManufacturingAutomation #Efficiency #Productivity

Title: Automatic Injection Molding System for Contact Plugs with 4x4 Insert Handling

Introduction:

The following tilter is designed to automate the injection molding process for contact plugs, while also incorporating automatic handling of 4x4 inserts. This system aims to enhance efficiency, precision, and overall productivity in contact plug manufacturing.

Features and Benefits:

1. Automated Injection Molding: The tilter integrates with an injection molding machine to automate the molding process of contact plugs. This eliminates the need for manual intervention, reducing labor costs and increasing production speed.

2. 4x4 Insert Handling: The tilter incorporates an automatic handling system specifically designed for 4x4 inserts. It efficiently loads and positions the inserts into the mold, ensuring accurate placement and minimizing the risk of errors or misalignment during the injection process.

3. Enhanced Precision and Consistency: By automating the injection molding process, the tilter ensures consistent and precise molding of contact plugs. This eliminates variations caused by human error, resulting in uniform product quality and reducing the chances of defects or rejects.

4. Increased Production Efficiency: The integration of automatic handling for 4x4 inserts significantly enhances production efficiency. The tilter streamlines the entire manufacturing process, reducing downtime and maximizing output.

5. Flexibility and Customization: The tilter can be customized to accommodate different contact plug designs and sizes. It offers flexibility in handling various types of inserts, allowing for versatility in production and adapting to specific manufacturing requirements.

6. User-Friendly Interface: The tilter features a user-friendly interface that allows operators to easily control and monitor the injection molding and handling processes. The interface provides real-time data, enabling operators to make informed decisions and troubleshoot any issues promptly.

7. Safety Measures: The tilter incorporates safety features such as sensors and emergency stops to ensure operator safety during operation. It adheres to relevant safety standards, minimizing the risk of accidents or injuries.

Conclusion:

The tilter for automatic injection molding of contact plugs with automatic handling of 4x4 inserts offers numerous benefits, including increased production efficiency, enhanced precision and consistency, and improved overall product quality. By eliminating manual handling and integrating automation, this system optimizes the manufacturing process, leading to higher productivity and reduced costs.Handling Machine

#Automatic #injection #molding #contactplugs #automatic #handling #inserts