Title: High-Speed Industrial Packing Line for Inspection and Packaging of 36,000 Syringes per Hour

Description:

Introduction:

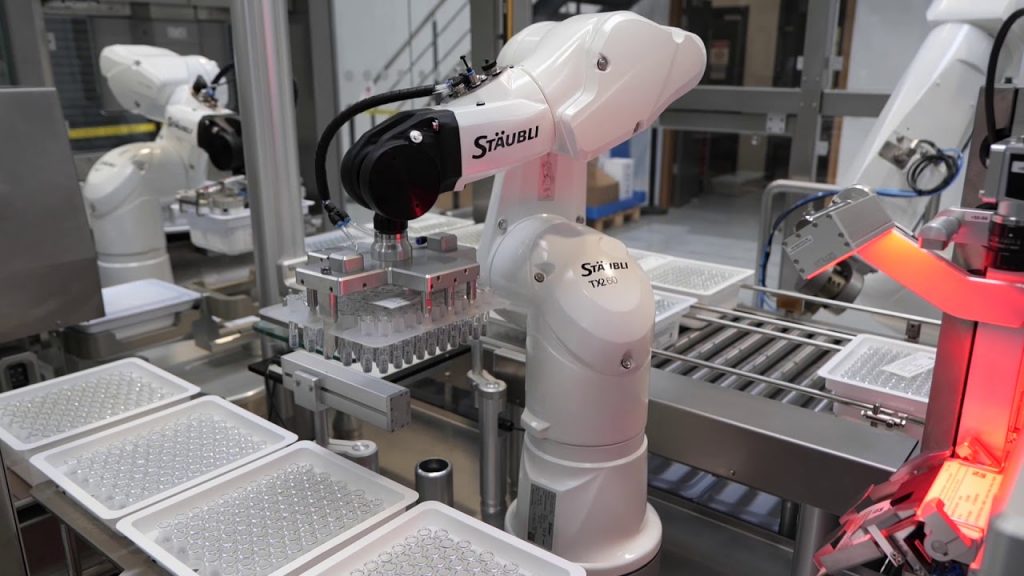

Welcome to our video showcasing an advanced and efficient Industrial Packing Line that specializes in inspecting and packaging a staggering 36,000 syringes per hour. In this video, we will delve into the operations of a compact and flexible robotic cell that handles the end-of-line inspection, labeling, and palletizing of these syringes, ensuring top-notch quality and productivity.

Video Content:

Our Industrial Packing Line is a game-changer in the pharmaceutical industry, revolutionizing the process of syringe production. With an impressive capacity of 36,000 syringes per hour, this state-of-the-art system guarantees optimal efficiency and precision.

Key Highlights:

1. Inspection: The first step of the packing line involves a meticulous inspection process, where every syringe undergoes a thorough examination. Our advanced technology ensures that only syringes meeting the highest quality standards proceed to the next stage.

2. Packaging: Once inspected, the syringes are carefully packaged using cutting-edge automation. This guarantees that each syringe is securely sealed and protected, maintaining its integrity throughout the transportation and storage process.

3. Robotic Cell: Our compact and flexible robotic cell plays a crucial role in the end-of-line operations. Equipped with advanced sensors and intelligent algorithms, this robotic system efficiently handles the inspection, labeling, and palletizing of the syringes, streamlining the entire process.

4. Quality Control: Our packing line is designed with a strong emphasis on quality control. We prioritize accuracy and precision, ensuring that each syringe is properly labeled, coded, and traceable throughout its lifecycle.

Key Takeaways:

- Our Industrial Packing Line offers a remarkable capacity of 36,000 syringes per hour, significantly boosting productivity and reducing manual labor.

- The advanced robotic cell efficiently handles inspection, labeling, and palletizing, resulting in a seamless and automated process.

- With a strong focus on quality control, our packing line guarantees that each syringe meets the highest industry standards.

- Our system ensures the integrity and traceability of syringes, enhancing overall efficiency and customer satisfaction.

Call to Action:

If you found this video informative and insightful, we encourage you to give it a thumbs up, subscribe to our channel for more valuable content, and share it with your colleagues and friends who might benefit from it.

Additional Tags and Keywords:

Industrial Packing Line, Inspection and Packaging, 36,000 Syringes per Hour, Robotic Cell, End-of-Line Inspection, Labeling, Palletizing, High-Speed Packaging, Pharmaceutical Industry, Quality Control, Automation, Efficiency, Productivity.

Hashtags:

#IndustrialPackingLine #HighSpeedPackaging #PharmaceuticalAutomation #SyringePackaging #RoboticCell #QualityControl

Title: Inspection and Packaging Tilter for High-Speed Syringe Manufacturing

Introduction:

The inspection and packaging of syringes in a high-speed manufacturing environment can be a challenging task. To streamline this process and enhance efficiency, a specialized tilter can be implemented. This tilter will facilitate the inspection and packaging of 36,000 syringes per hour, ensuring accuracy, consistency, and productivity. This article outlines the key features and benefits of such a tilter.

Key Features:

1. Automated Tilter Mechanism: The tilter will be equipped with an automated system capable of tilting the syringes at a high-speed rate, aligning them for inspection and packaging. This mechanism will significantly reduce manual labor and increase efficiency.

2. Precise and Gentle Handling: The tilter will be designed to handle the syringes with utmost care, ensuring that no damage or contamination occurs during the tilting process. This will maintain the integrity of each syringe and prevent any disturbances in the packaging process.

3. Adjustable Tilt Angles: The tilter will have adjustable tilt angles to accommodate different inspection requirements. This flexibility will allow for thorough inspection of the syringes from all angles, ensuring that any defects or imperfections are detected before packaging.

4. Integrated Inspection Technology: The tilter will be integrated with advanced inspection technology, such as optical sensors and machine vision systems, to detect any abnormalities in the syringes. This will enable real-time quality control and minimize the risk of defective products reaching the market.

5. High-Speed Conveyor System: The tilter will be synchronized with a high-speed conveyor system to ensure a continuous flow of syringes throughout the inspection and packaging process. This seamless integration will maximize productivity and minimize bottlenecks.

Benefits:

1. Increased Throughput: With the ability to process 36,000 syringes per hour, the tilter will significantly enhance the manufacturing throughput, reducing production time and meeting demanding market demands.

2. Improved Quality Control: The integrated inspection technology will enable thorough quality control, minimizing the risk of flawed or defective syringes reaching the market. This will enhance customer satisfaction and uphold the reputation of the manufacturing company.

3. Cost Reduction: By automating the inspection and packaging process, the tilter will reduce the need for manual labor, thereby lowering operational costs. Additionally, the precise handling will minimize product wastage due to damage or contamination, further reducing costs.

4. Enhanced Worker Safety: The tilter will eliminate the need for workers to manually handle syringes, reducing the risk of repetitive strain injuries and other occupational hazards. This will create a safer working environment for employees.

Conclusion:

The implementation of an inspection and packaging tilter for high-speed syringe manufacturing offers numerous benefits, including increased throughput, improved quality control, cost reduction, and enhanced worker safety. By incorporating advanced automation and inspection technology, this tilter will revolutionize the production process, ensuring the efficient and accurate inspection and packaging of 36,000 syringes per hour. Automatic Packing Line

#Inspection #packaging #syringes #hour