If you're curious about how a semi-automatic labeling machine works, you've come to the right place. In this article, we will explore the fascinating world of labeling machines and delve into the intricate details of their operation. Whether you're a business owner looking to streamline your labeling process or simply an individual interested in the mechanics behind these machines, we've got you covered.

Labeling machines play a crucial role in various industries, ensuring that products are properly labeled with precision and accuracy. From bottles to packages, these machines offer a robust and unrivaled level of precision, guaranteeing label accuracy every time.

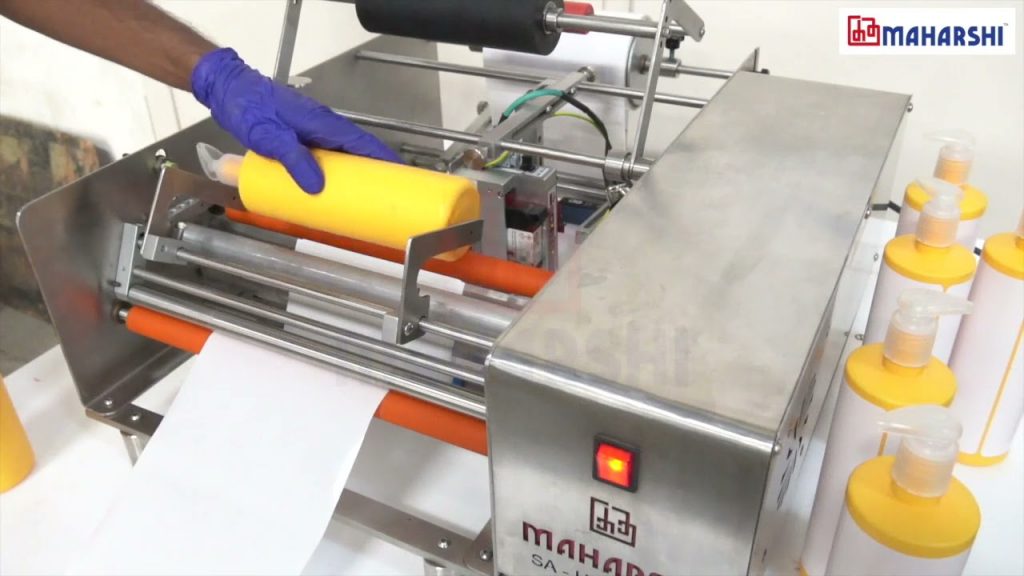

To understand how a semi-automatic labeling machine works, let's take a closer look at its key components and the process it follows:

1. Label Dispenser: The labeling machine is equipped with a label dispenser that holds a roll of labels. These labels are typically made of adhesive material and are pre-printed with the required information.

2. Product Placement: The product to be labeled is placed in the designated position on the machine's conveyor or platform. This can be done manually or with the help of an automated system.

3. Label Application: Once the product is in place, the labeling machine activates the label dispenser, which dispenses the label onto the product's surface. The machine ensures precise placement of the label through advanced sensors and positioning mechanisms.

4. Labeling Parameters: Before the labeling process begins, the operator can set various parameters on the machine, such as label size, label position, and labeling speed. These parameters can be adjusted based on the specific requirements of the product being labeled.

5. Repeat Process: The labeling machine continues to repeat the labeling process for each subsequent product, ensuring a consistent and efficient labeling operation.

Semi-automatic labeling machines offer several advantages for businesses. They are cost-effective compared to fully automatic machines, making them a popular choice for small to medium-sized enterprises. Additionally, these machines are versatile and can handle a wide range of products, making them suitable for various industries such as food and beverage, pharmaceuticals, cosmetics, and more.

In terms of SEO, it is important to mention the keywords "Labeling Machine" throughout the article to improve its visibility in search engine results. This helps potential customers who are specifically searching for information about labeling machines to find this article easily.

In conclusion, a semi-automatic labeling machine is a powerful tool that enables businesses to achieve robust and unrivaled precision in label accuracy. Understanding how these machines work can provide valuable insights for businesses looking to enhance their labeling processes. Whether you're a business owner or simply curious about the intricacies of labeling machines, this article has hopefully shed some light on this fascinating technology.

Check the coil packing solution with a leading manufacturer for a professional solution just here:

At the last section, Rewrite the "Check the coil packing solution with leading manufacturer for the professional solution just here: Labeling Machine

"Efficient and Versatile Labelling Solutions for Bottles: Simplify Your Labeling Process with Cutting-Edge Technology"