Used Shrinking Machine: The Ultimate Solution for Efficient Packaging

Introduction

In today's fast-paced world, efficient packaging plays a crucial role in ensuring the safe transportation and storage of products. With the increasing demand for streamlined packaging processes, the importance of advanced machinery like Used Shrinking Machines cannot be emphasized enough. In this article, we will explore the various aspects of Used Shrinking Machines, including their functionality and benefits, with a specific focus on Part 230 Steel pipe shrinking machine for large-diameter steel pipe shrinking butt joint.

Explanatory Style

What is a Used Shrinking Machine?

A Used Shrinking Machine is a state-of-the-art packaging equipment designed to wrap products tightly in shrink film. This machine utilizes heat to shrink the film around the product, providing a secure and tamper-proof packaging solution. It is widely used in industries such as food and beverage, pharmaceuticals, electronics, and many others.

Advantages of Using a Used Shrinking Machine

1. Enhanced Product Protection: The tight shrink film wrap provided by a Used Shrinking Machine ensures that the products are protected from external factors such as moisture, dust, and contaminants during transportation and storage.

2. Improved Aesthetic Appeal: The shrink film tightly conforms to the shape of the product, giving it a sleek and professional appearance. This enhances the overall presentation of the product and promotes a positive brand image.

3. Cost-effective Packaging Solution: Used Shrinking Machines offer cost savings in terms of material usage and labor. The shrink film is economical compared to other packaging materials, and the automated process reduces the need for manual labor, thereby increasing productivity and efficiency.

4. Versatility: Used Shrinking Machines can accommodate a wide range of product sizes and shapes, making them suitable for various industries. From small consumer goods to large industrial components, these machines can handle it all.

5. Environmental-friendly: The shrink film used in these machines is recyclable, making it an eco-friendly packaging solution. This aligns with the growing demand for sustainable practices in the industry.

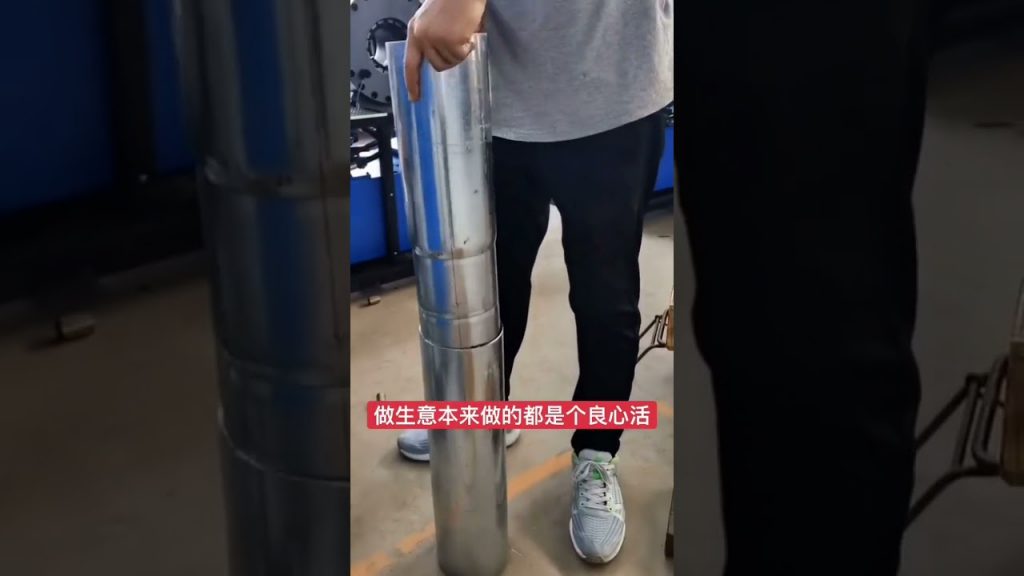

Part 230 Steel Pipe Shrinking Machine: A Game Changer in Large-diameter Steel Pipe Butt Joint

The Part 230 Steel pipe shrinking machine is a specialized Used Shrinking Machine designed specifically for large-diameter steel pipe shrinking butt joint applications. It offers unique features and capabilities that make it a game changer in the industry.

Unique Features of Part 230 Steel Pipe Shrinking Machine

1. High Efficiency: This machine is equipped with advanced technology that ensures fast and efficient shrinking of large-diameter steel pipes. It significantly reduces the time required for packaging, leading to improved productivity.

2. Precise Shrinkage: The Part 230 Steel pipe shrinking machine ensures precise shrinkage of the film around the steel pipes, providing a tight and secure packaging. This minimizes the risk of damage during transportation and handling.

3. Robust Construction: The machine is built with high-quality materials, ensuring durability and long-term reliability. It can withstand the demanding industrial environment and deliver consistent performance.

4. Easy Operation: The Part 230 Steel pipe shrinking machine is designed for user convenience. It features a user-friendly interface and intuitive controls, making it easy to operate even for non-technical personnel.

5. Safety Features: Safety is a top priority in any industrial setting. This machine incorporates safety features such as emergency stop buttons and protective shields to ensure the well-being of operators.

In-depth Analysis Style

The Future of Used Shrinking Machines

As technology continues to evolve, the future of Used Shrinking Machines looks promising. Advancements in automation, artificial intelligence, and robotics will further enhance the capabilities of these machines. They will become more intelligent, allowing for better customization, increased efficiency, and improved product handling.

Used Shrinking Machines will also play a vital role in meeting the growing demand for sustainable packaging solutions. Manufacturers will continue to develop environmentally-friendly shrink films and innovative machine designs that reduce material waste and energy consumption.

Conclusion

Used Shrinking Machines have revolutionized the packaging industry by providing efficient, cost-effective, and environmentally-friendly packaging solutions. The Part 230 Steel pipe shrinking machine, specifically designed for large-diameter steel pipe butt joint applications, offers unparalleled performance and reliability. As the industry continues to evolve, these machines will play a pivotal role in meeting the changing demands of the market.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

(Note: This section should be replaced with the appropriate call-to-action or conclusion based on the specific requirements of the sales engineer or company.) Shrinking Machine

"Efficient Steel Pipe Shrinking Machine: Large-Diameter Butt Joint Process & Cost-Effective Used Options!"