Title: Ultimate Guide to Material Handling Machines, Warehouse Equipment, and Storage Systems | Rent Industrial Storage and Handling Equipment

Description:

Introduction:

Welcome to our comprehensive guide on material handling machines, warehouse equipment, and storage systems. In this video, we will explore the various aspects of these essential tools for efficient operations in industries and warehouses. Whether you're looking to understand the fundamentals or seeking information on renting industrial storage and handling equipment, this guide has got you covered.

Video Content:

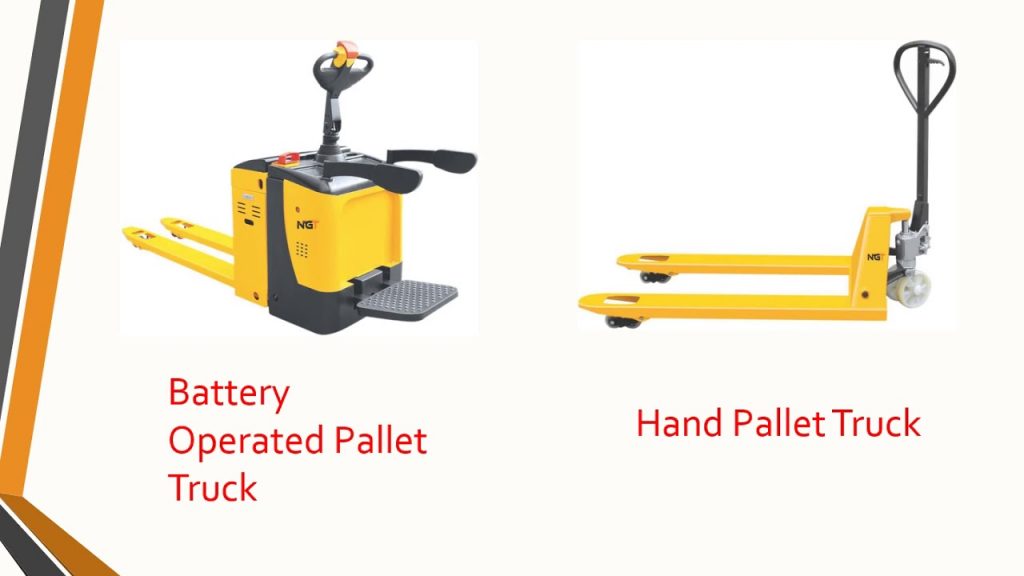

- Understanding Material Handling Machines: Discover the different types of material handling machines available in the market, including forklifts, pallet jacks, conveyors, and more. Learn about their benefits, features, and specific applications in various industries.

- Warehouse Equipment and Storage Systems: Dive into the world of warehouse equipment and storage systems, such as shelving units, racks, mezzanines, and automated storage and retrieval systems (AS/RS). Explore their functionalities, space optimization techniques, and the advantages they bring to warehouses and distribution centers.

- Renting Warehouse Equipment: If you're considering renting warehouse equipment rather than making a long-term investment, this segment is for you. We'll discuss the benefits of renting, the types of equipment available for rent, and the factors to consider when choosing a rental provider.

- Industrial Storage Systems: Learn about the importance of efficient storage systems in industrial settings. Discover how these systems enhance productivity, streamline operations, and maximize space utilization. Gain insights into various types of storage systems, such as bulk storage, pallet racking, and vertical storage solutions.

Call to Action:

If you found this guide helpful, don't forget to like, subscribe, and share it with others who might benefit from this valuable information. Stay tuned for more informative videos on material handling, warehouse equipment, and storage systems.

Additional Tags: material handling machines, warehouse equipment, storage systems, industrial storage, handling equipment rental, warehouse solutions, efficient storage, warehouse optimization, industrial operations, material handling solutions

Hashtags: #MaterialHandling #WarehouseEquipment #StorageSystems #IndustrialStorage #HandlingEquipmentRental #WarehouseOptimization

Title: Enhancing Efficiency and Safety: A Comprehensive Guide to Warehouse Equipment's and Storage Systems

Introduction:

In today's fast-paced world, efficient warehousing is crucial for businesses to stay competitive. An optimized warehouse equipment and storage system not only enables smooth operations but also ensures employee safety. This guide aims to provide a comprehensive overview of warehouse equipment's and storage systems, offering valuable insights into their functionality, selection criteria, and maintenance practices.

Chapter 1: Understanding Warehouse Equipment's

1.1 Forklifts: Types, features, and safe operation

1.2 Conveyor Systems: Benefits, types, and integration

1.3 Pallet Jacks: Manual vs. electric, load capacity, and maintenance

1.4 Automated Guided Vehicles (AGVs): Advancements and integration into the warehouse workflow

1.5 Racking Systems: Different types, load capacities, and layout optimization

Chapter 2: Selecting the Right Warehouse Equipment's

2.1 Assessing operational requirements and space constraints

2.2 Evaluating equipment options based on efficiency and cost-effectiveness

2.3 Considering safety features and ergonomic factors

2.4 Analyzing maintenance and repair requirements

Chapter 3: Optimizing Storage Systems

3.1 Pallet Racking Systems: Types, configurations, and load capacity calculations

3.2 Shelving Systems: Understanding different types and their applications

3.3 Mezzanine Floors: Maximizing vertical space and storage capacity

3.4 Automated Storage and Retrieval Systems (AS/RS): Benefits, types, and implementation considerations

Chapter 4: Safety Measures and Best Practices

4.1 Training employees on equipment operation and safety protocols

4.2 Regular inspections and maintenance procedures

4.3 Implementing safety features such as guardrails, safety gates, and warning signs

4.4 Proper load handling techniques and weight distribution awareness

Chapter 5: Maintenance and Troubleshooting

5.1 Scheduled maintenance practices for warehouse equipment's

5.2 Common troubleshooting techniques and quick fixes

5.3 Importance of regular equipment inspections and servicing

5.4 Engaging professional technicians for complex repairs

Chapter 6: Future Trends and Innovations

6.1 Robotics and artificial intelligence in warehouse operations

6.2 Internet of Things (IoT) integration for real-time monitoring and inventory control

6.3 Predictive maintenance and data-driven decision-making

6.4 Sustainable and eco-friendly warehouse equipment's and storage systems

Conclusion:

By understanding the different types of warehouse equipment's, selecting the right solutions, and implementing robust safety measures, businesses can enhance efficiency and productivity while ensuring a safe working environment. Continual maintenance and staying updated with emerging trends are crucial for staying ahead in the ever-evolving warehouse industry.Handling Machine

#Warehouse #Equipments #Storage #System