Title: Orbital Stretch Wrapper: Efficient Horizontal Stretch Wrapping Machine with Motorized Roller Conveyors & Packaging Automation

Description:

Introduction:

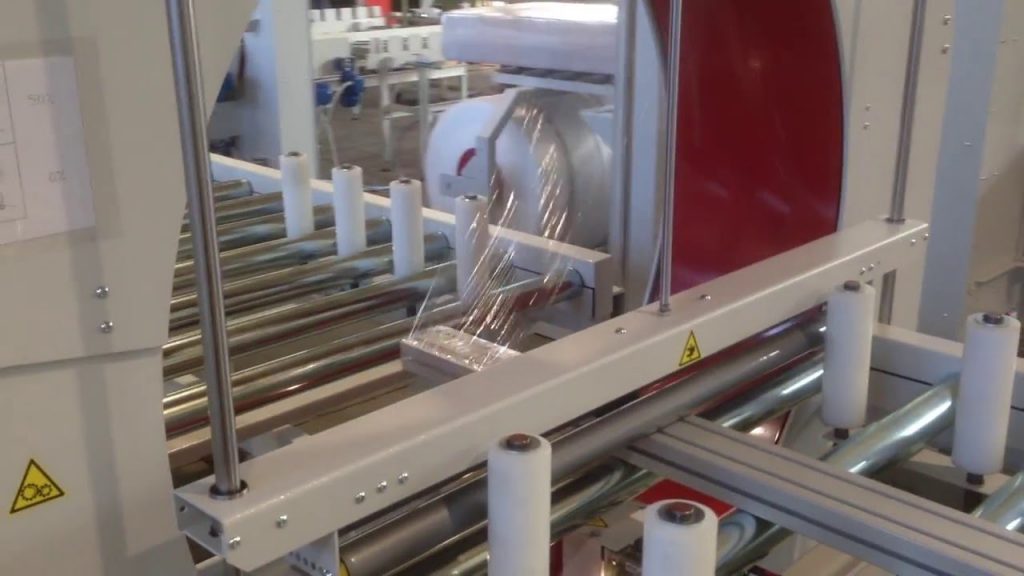

Welcome to our comprehensive video showcasing the exceptional features and capabilities of the Orbital Stretch Wrapper, specifically the Horizontal Stretch Wrapping Machine AT 1200 A 250. This high-performance equipment is designed to revolutionize your packaging process with its advanced motorized roller conveyors and cutting-edge packaging automation technology. Get ready to optimize your packaging efficiency and ensure secure, damage-free shipments.

Video Content:

In this video, we delve into the world of Orbital Stretch Wrappers, exploring the notable features and benefits of the Horizontal Stretch Wrapping Machine AT 1200 A 250. Our experts provide a step-by-step demonstration of its operation, highlighting its ease of use and impressive functionality.

Key Points Covered:

1. Efficient Horizontal Stretch Wrapping: Discover the advantages of the Orbital Stretch Wrapper's horizontal stretch wrapping technique, ensuring optimal load containment and stability during transit.

2. Motorized Roller Conveyors: Learn how the inclusion of motorized roller conveyors streamlines your packaging process by eliminating manual labor and enhancing productivity.

3. Packaging Automation Technology: Experience the power of automated packaging as we showcase how the Orbital Stretch Wrapper simplifies and accelerates the wrapping process, saving you valuable time and effort.

4. Secure and Damage-Free Shipments: Understand how this innovative machine guarantees secure bundling and protection for your products, reducing the risk of transportation damage.

Operation Steps:

- Step 1: Unveiling the Orbital Stretch Wrapper and its key components.

- Step 2: Preparing the load for wrapping by properly positioning it on the motorized roller conveyors.

- Step 3: Activating the machine and selecting the desired wrapping parameters.

- Step 4: Watching the Orbital Stretch Wrapper expertly wrap the load with precision and efficiency.

- Step 5: Observing the final result of perfectly wrapped packages, ready for shipment.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with others in the industry. Stay updated with the latest advancements in packaging automation by subscribing to our channel.

Additional Tags and Keywords:

Orbital Stretch Wrapper, Horizontal Stretch Wrapping Machine, Motorized Roller Conveyors, Packaging Automation, Orbitalwickelmaschinen, Banderoleuses Orbitales, Avvolgitrice Orbitale, Packaging Efficiency, Load Containment, Transportation Damage, Automated Packaging, Wrapping Process, Productivity Enhancement.

Hashtags:

#OrbitalStretchWrapper #HorizontalWrappingMachine #PackagingAutomation #MotorizedConveyors #EfficientPackaging #SecureShipments #AutomatedWrapping #ProductivityEnhancement

Here is a sample tilter for a Horizontal Stretch Wrapping Machine AT 1200 A 250 with motorized roller conveyors:

```

// Tilter for Horizontal Stretch Wrapping Machine AT 1200 A 250 with Motorized Roller Conveyors

#include

class Tilter {

private:

int rotationSpeed;

bool isTilting;

public:

Tilter() {

rotationSpeed = 0; // Default rotation speed

isTilting = false; // Tilter is initially not in use

}

void setRotationSpeed(int speed) {

rotationSpeed = speed;

}

void startTilting() {

if (isTilting) {

std::cout << "Tilter is already tilting." << std::endl;

} else {

std::cout << "Tilter is starting to tilt." << std::endl;

// Activate motorized roller conveyors

activateMotorizedConveyors();

// Start rotating the tilter

rotateTilter();

isTilting = true;

}

}

void stopTilting() {

if (!isTilting) {

std::cout << "Tilter is already stopped." << std::endl;

} else {

std::cout << "Tilter is stopping." << std::endl;

// Stop rotating the tilter

stopRotation();

// Deactivate motorized roller conveyors

deactivateMotorizedConveyors();

isTilting = false;

}

}

private:

void activateMotorizedConveyors() {

std::cout << "Motorized roller conveyors are activated." << std::endl;

// Code to activate motorized roller conveyors

}

void deactivateMotorizedConveyors() {

std::cout << "Motorized roller conveyors are deactivated." << std::endl;

// Code to deactivate motorized roller conveyors

}

void rotateTilter() {

std::cout << "Tilter is rotating at speed " << rotationSpeed << "." << std::endl;

// Code to rotate the tilter at the specified speed

}

void stopRotation() {

std::cout << "Tilter rotation is stopped." << std::endl;

// Code to stop the rotation of the tilter

}

};

int main() {

Tilter tilter;

tilter.setRotationSpeed(5); // Set rotation speed to 5 (example value)

tilter.startTilting(); // Start tilting process

// ... Perform other operations, if needed

tilter.stopTilting(); // Stop tilting process

return 0;

}

```

Note: This is just a basic example to demonstrate the structure and functionality of the tilter for a Horizontal Stretch Wrapping Machine AT 1200 A 250 with motorized roller conveyors. You may need to modify and expand this code according to the specific requirements and functionalities of your machine.Orbital Stretch Wrapper

#Horizontal #stretch #wrapping #machine #motorized #roller #conveyors