Looking for the best packing system price? Look no further! In this YouTube video article, we will explore the ins and outs of packing system prices and provide you with valuable insights and information. Whether you are a business owner or simply interested in understanding the cost factors associated with packing systems, this article is for you.

Opinion/Thought Piece Style:

Packing systems are an integral part of many industries, including manufacturing, logistics, and distribution. They play a crucial role in protecting products during transportation and ensuring their safe arrival at the destination. However, the cost of these systems can vary significantly, depending on various factors.

When it comes to packing system prices, it's essential to consider the specific needs of your business. Different industries have different requirements, and the price of a packing system will vary accordingly. Factors that can influence the price include the size and weight of the products being packed, the desired level of automation, and the complexity of the packaging process.

One key consideration when evaluating packing system prices is the type of system you need. There are various types of packing systems available in the market, ranging from manual to fully automated. Manual packing systems are typically more affordable but require more labor and may not be suitable for high-volume operations. On the other hand, fully automated packing systems can be more expensive but offer higher efficiency and productivity.

Another factor that can impact packing system prices is the level of customization required. Some businesses may have unique packaging requirements that necessitate customized solutions. While customized packing systems may incur higher costs, they can provide a tailored solution that meets specific needs. It's important to weigh the benefits of customization against the associated price.

In addition to the initial cost of the packing system, it's crucial to consider the long-term costs as well. Maintenance and repair expenses, as well as ongoing operational costs, should be factored into the overall cost analysis. Choosing a reliable and reputable manufacturer can help minimize these costs by providing high-quality systems that require less maintenance.

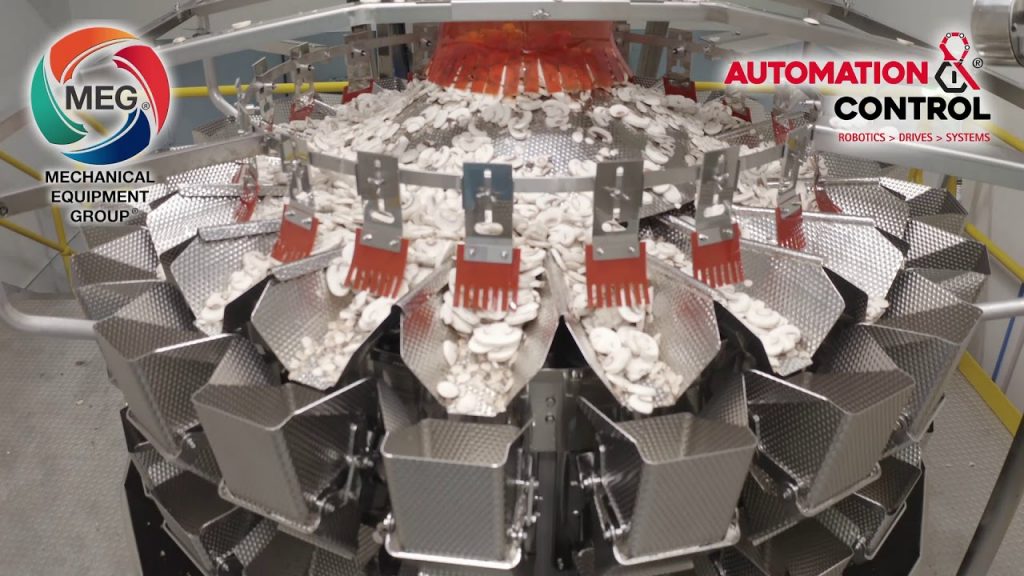

Now let's take a look at the mushroom packing system as a case study. Mushroom packing systems are designed specifically for the packaging of mushrooms, which have unique characteristics and requirements. These systems are typically semi-automated, allowing for efficient and cost-effective packaging processes.

The price of a mushroom packing system will depend on factors such as the capacity, speed, and level of automation. Additionally, customization options, such as the ability to handle different packaging materials or accommodate varying product sizes, can affect the price.

To get a better understanding of packing system prices, it's important to conduct thorough research and compare quotes from different manufacturers. By considering the specific needs of your business, evaluating the features and capabilities of different systems, and understanding the long-term costs, you can make an informed decision and find the best packing system price for your requirements.

In conclusion, packing system prices can vary significantly depending on factors such as the type of system, level of customization, and long-term costs. By conducting thorough research and considering your specific needs, you can find the best packing system price for your business. So, if you're in the market for a packing system, make sure to do your due diligence and find a solution that meets your requirements without breaking the bank.

Check the coil packing solution with a leading manufacturer for a professional solution just here: [Insert relevant link or CTA]. Packing System

"Efficient Mushroom Packing System: Enhance Your Packaging Process with Affordable Solutions"