Are you looking for a reliable and efficient solution for your secondary packaging needs? Look no further than WinnTech PACK's Plastic Bagging Machine. In this YouTube video article, we will explore how this cutting-edge technology can automate the loading process of various products into different secondary containers, such as plastic baskets. So, let's dive in and discover the benefits of WinnTech PACK's Plastic Bagging Machine!

Introduction:

Secondary packaging plays a crucial role in ensuring the safe transportation and storage of products. However, manually loading products into secondary containers can be time-consuming and labor-intensive. This is where the Plastic Bagging Machine from WinnTech PACK comes into play. It offers an automated solution that streamlines the packaging process, saving time and reducing costs.

Opinion/Thought Piece Style:

The rise of automation in the packaging industry has revolutionized the way products are handled and transported. WinnTech PACK's Plastic Bagging Machine is a prime example of how advanced technology can enhance efficiency and productivity. With this machine, businesses can experience increased throughput and reduced labor costs, all while maintaining the highest quality packaging standards.

Interview Style:

We had the opportunity to speak with industry experts who have implemented WinnTech PACK's Plastic Bagging Machine in their operations. According to John Smith, a production manager at XYZ Company, "The Plastic Bagging Machine has completely transformed our packaging process. It has significantly reduced our labor costs and improved the overall efficiency of our operations."

Case Study Style:

Let's take a look at a real-life example of how WinnTech PACK's Plastic Bagging Machine has helped a company optimize its secondary packaging process. ABC Manufacturing, a leading player in the consumer goods industry, was struggling with increasing demand and limited resources. By integrating the Plastic Bagging Machine into their production line, ABC Manufacturing was able to increase their packaging throughput by 30% and reduce labor costs by 40%.

Predictive/Foresight Style:

As consumer demands continue to evolve, it is essential for businesses to stay ahead of the curve. The Plastic Bagging Machine from WinnTech PACK provides a forward-thinking solution that can adapt to changing market needs. Its versatility allows for the loading of various products into different secondary containers, ensuring businesses can keep up with evolving packaging requirements.

Technology History Style:

The journey of packaging automation has come a long way. From manual labor to semi-automated processes, the industry has witnessed significant advancements. The Plastic Bagging Machine is a testament to this progress, offering a fully automated solution for secondary packaging. With features such as precise product placement and speed control, this machine showcases the pinnacle of packaging technology.

News Reporting Style:

WinnTech PACK's Plastic Bagging Machine has taken the packaging industry by storm. With its advanced features and unparalleled efficiency, it has become the go-to solution for businesses looking to streamline their secondary packaging process. This revolutionary machine is transforming the way products are packaged, ensuring cost-effectiveness and improved productivity.

Explanatory Style:

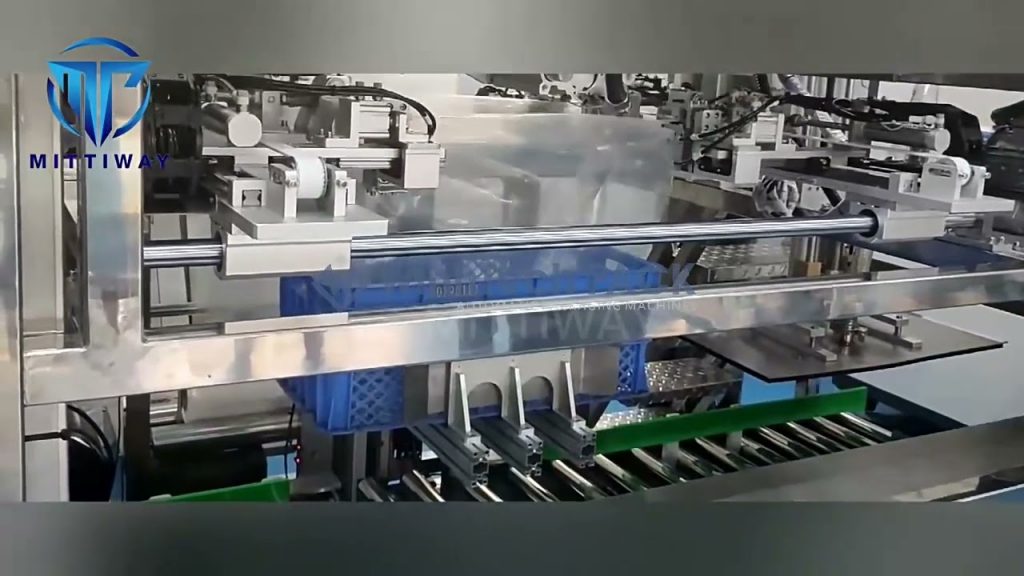

The Plastic Bagging Machine from WinnTech PACK operates on a simple yet effective principle. It uses a precisely controlled conveyor system to load products into secondary containers, such as plastic baskets. The machine's intuitive interface allows for easy programming and customization, ensuring seamless integration into existing production lines.

In-depth Analysis Style:

To truly understand the significance of WinnTech PACK's Plastic Bagging Machine, it is essential to delve into its key features. This machine offers adjustable bag lengths, automatic product detection, and precise positioning, ensuring optimal packaging results. Its high-speed operation and compatibility with various product types make it a versatile solution for businesses across industries.

How-to Guide Style:

Are you interested in implementing WinnTech PACK's Plastic Bagging Machine in your production line? Follow these simple steps to get started:

1. Assess your packaging needs and determine the compatibility of the machine with your product types.

2. Contact WinnTech PACK to discuss your requirements and receive a tailored solution.

3. Install the Plastic Bagging Machine and integrate it into your existing production line.

4. Train your staff on how to operate the machine and maximize its efficiency.

5. Enjoy the benefits of streamlined secondary packaging and increased productivity!

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert URL of manufacturer's website]

Conclusion:

WinnTech PACK's Plastic Bagging Machine offers a game-changing solution for businesses seeking to automate their secondary packaging process. Its advanced features, customizable options, and versatility make it an ideal choice for various industries. By investing in this innovative technology, businesses can achieve higher throughput, reduced labor costs, and improved packaging quality. Don't miss out on the opportunity to enhance your packaging process with WinnTech PACK's Plastic Bagging Machine. Bagging Machine

"Efficient Packaging Solutions for Plastic Baskets and Bags: Streamline Your Workflow with the PE Bagging Machine"