Used Packing System: A Reliable Solution for Efficient Packaging

Introduction:

In today's fast-paced world, efficient packaging plays a crucial role in ensuring the smooth flow of goods from manufacturers to consumers. Companies are constantly seeking innovative solutions to streamline their packaging processes and enhance productivity. One such solution is the Used Packing System, which offers numerous benefits for businesses looking to optimize their packaging operations. In this article, we will explore the working principle of the Powder Packing Machine, a key component of the Used Packing System, and discuss its importance in the industry.

Explanatory Style:

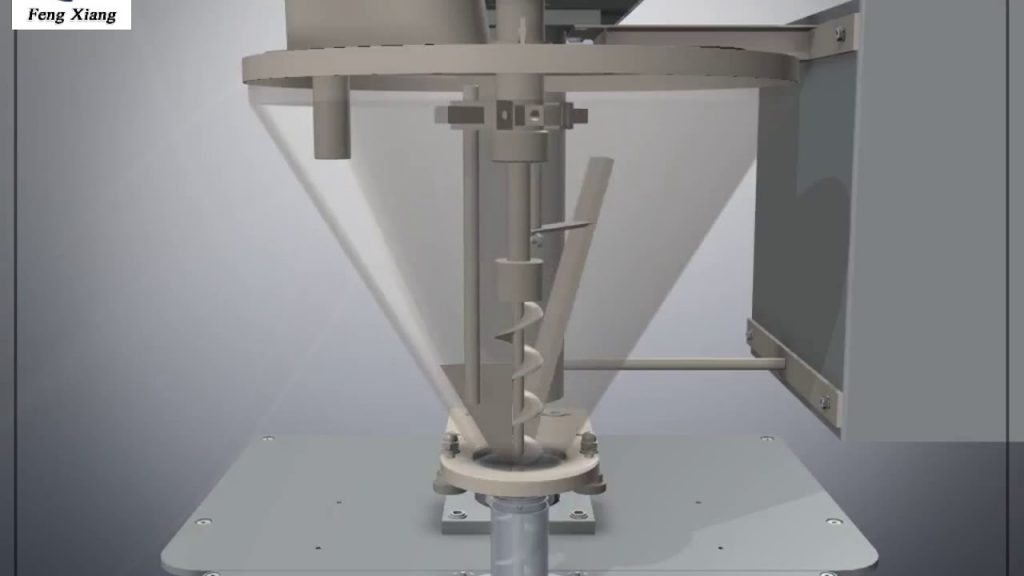

The Used Packing System is a comprehensive packaging solution that involves the utilization of various machines and equipment to streamline the packaging process. Among these, the Powder Packing Machine stands out as a versatile tool capable of efficiently packaging powdered products.

The working principle of the Powder Packing Machine revolves around the precise measurement and filling of powdered substances into appropriate containers. This automated process ensures accuracy and consistency, eliminating the risk of human error and reducing material wastage. The machine utilizes advanced technology to precisely weigh and dispense the desired quantity of powder, ensuring that each package is filled to perfection.

The Importance of the Used Packing System:

The Used Packing System offers numerous advantages for businesses in various industries. One of the key benefits is increased efficiency. By automating the packaging process, companies can significantly reduce manual labor, allowing their workforce to focus on other essential tasks. This not only saves time but also enhances overall productivity.

Additionally, the Used Packing System helps minimize material wastage. With its precise measuring capabilities, the Powder Packing Machine ensures that the exact amount of powder is dispensed into each package, minimizing product loss and maximizing resource utilization. This not only contributes to cost savings but also helps businesses maintain their sustainability goals by reducing their environmental footprint.

Moreover, the Used Packing System enhances product quality and customer satisfaction. The automated packaging process ensures consistent and accurate filling, preventing under or overfilling of packages. This, in turn, helps businesses deliver high-quality products to their customers, fostering trust and loyalty.

Case Study Style:

To further understand the impact of the Used Packing System, let's take a look at a real-life case study. ABC Manufacturing, a leading food processing company, implemented the Used Packing System in their packaging line. The incorporation of the Powder Packing Machine resulted in a significant improvement in their packaging efficiency. The automated process allowed them to package their powdered products at a much faster rate, reducing their overall production time. This, in turn, enabled them to meet the growing market demand and expand their customer base.

Conclusion:

The Used Packing System, with its advanced Powder Packing Machine, offers a reliable solution for businesses seeking to optimize their packaging operations. By automating the process, companies can enhance efficiency, minimize material wastage, and deliver high-quality products to their customers. The benefits of utilizing the Used Packing System are evident in various industries, and its importance in streamlining packaging processes cannot be overstated.

Check the coil packing solution with a leading manufacturer for the professional solution just here Packing System

"Efficient Powder Packing Machine: Discover How It Works and Its Application in Packing Systems"