Are you in need of a used shrinking machine? Look no further! In this article, we will explore the benefits of using a used shrinking machine and provide valuable insights into the manufacturing process of PVC shrink film. Whether you are a business owner or an individual looking for a reliable and cost-effective solution, this article will guide you through the world of used shrinking machines.

Narrative Structure:

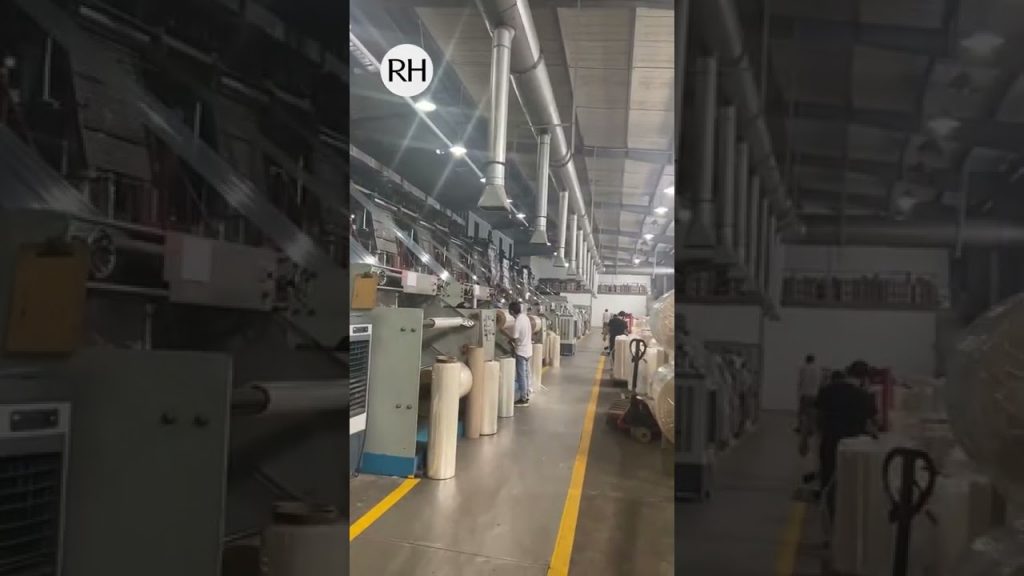

Let's begin our journey by understanding the concept of a used shrinking machine. A shrinking machine is a versatile piece of equipment used to package products by applying heat to a plastic film, causing it to shrink tightly around the item. This process not only protects the product from damage but also gives it a professional and appealing look.

Imagine you have a business that requires packaging a large number of products on a daily basis. Investing in a new shrinking machine may not always be economically feasible. This is where used shrinking machines come into the picture. These machines offer the same functionality as new ones but at a fraction of the cost. By opting for a used machine, you can save money and still achieve the desired packaging results.

Argumentative Structure:

Used shrinking machines have several advantages over their newer counterparts. Firstly, they are more cost-effective. You can often find high-quality used machines at significantly lower prices compared to new ones. This cost savings can be crucial, especially for small businesses or startups with limited budgets.

Secondly, used machines have a proven track record. They have been previously used and tested, so you can be confident in their performance and reliability. Many used machines come with warranties or guarantees, providing additional peace of mind.

Critical Structure:

When purchasing a used shrinking machine, it is important to consider the manufacturer and the condition of the machine. Look for reputable manufacturers who have a history of producing reliable and durable machinery. This will ensure that you are investing in a high-quality product that will stand the test of time.

Additionally, thoroughly inspect the machine before making a purchase. Check for any signs of wear and tear, and ask for a demonstration to ensure that all functions are in proper working order. It is also advisable to inquire about the maintenance history of the machine to get a better understanding of its overall condition.

Explanatory Structure:

Now, let's shift our focus to the manufacturing process of PVC shrink film. PVC (Polyvinyl Chloride) shrink film is a widely used packaging material known for its versatility and durability. It is produced through a combination of extrusion and cooling processes.

During the extrusion process, PVC resin is melted and forced through a die to form a continuous sheet of film. This film is then cooled down rapidly to solidify it. The thickness of the film can vary depending on the desired application and packaging requirements.

Once the PVC shrink film is manufactured, it can be used with a shrinking machine to package a wide range of products. The film is placed around the product, and when heat is applied, it shrinks tightly around the item, providing protection and enhancing its visual appearance.

In-depth Analysis Structure:

The use of PVC shrink film in combination with a shrinking machine offers numerous benefits. Firstly, it provides excellent protection against dust, moisture, and tampering. This is especially important for products that are sensitive to environmental factors or prone to damage during transportation.

Secondly, PVC shrink film is highly versatile and can be used for packaging various types of products, including food items, cosmetics, electronics, and more. Its transparency allows for easy product identification and enhances the aesthetics of the packaged item.

Comparative Structure:

Compared to other packaging materials, PVC shrink film offers superior clarity and durability. It is resistant to tearing and puncturing, ensuring that the packaged product remains intact throughout its journey from the manufacturer to the end-user.

Furthermore, PVC shrink film is compatible with different types of shrinking machines, making it a flexible choice for businesses with diverse packaging needs. Whether you are packaging small items or large objects, PVC shrink film can be customized to fit any size or shape.

Progressive Structure:

As technology continues to advance, the efficiency and capabilities of shrinking machines have greatly improved. Modern machines offer features such as adjustable heat settings, variable speed control, and user-friendly interfaces. These advancements contribute to increased productivity and ease of operation.

With the growing demand for sustainable packaging solutions, manufacturers have also started exploring eco-friendly alternatives to traditional PVC shrink film. Biodegradable shrink films made from materials like PLA (Polylactic Acid) are gaining popularity due to their reduced environmental impact.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Shrinking Machine

"Mastering PVC Shrink Film Manufacturing: Unveiling the Secrets Behind Efficient Production and Utilizing High-quality Used Shrinking Machines"