Streamlining Manufacturing in the FMCG & Pharma Industry with Case Erector Machine

In today's fast-paced market, the FMCG (Fast-Moving Consumer Goods) and Pharma industries face the constant challenge of meeting the rising demand for their products. To keep up with this demand, manufacturers in these sectors need to ensure that their production processes are streamlined and efficient. This is where the Case Erector Machine comes into play.

The Case Erector Machine is a revolutionary piece of equipment that is designed to automate the process of erecting and sealing cases. By using this machine, manufacturers can significantly increase their production output while reducing labor costs and minimizing errors. Let's take a closer look at how this machine can transform the manufacturing process in these industries.

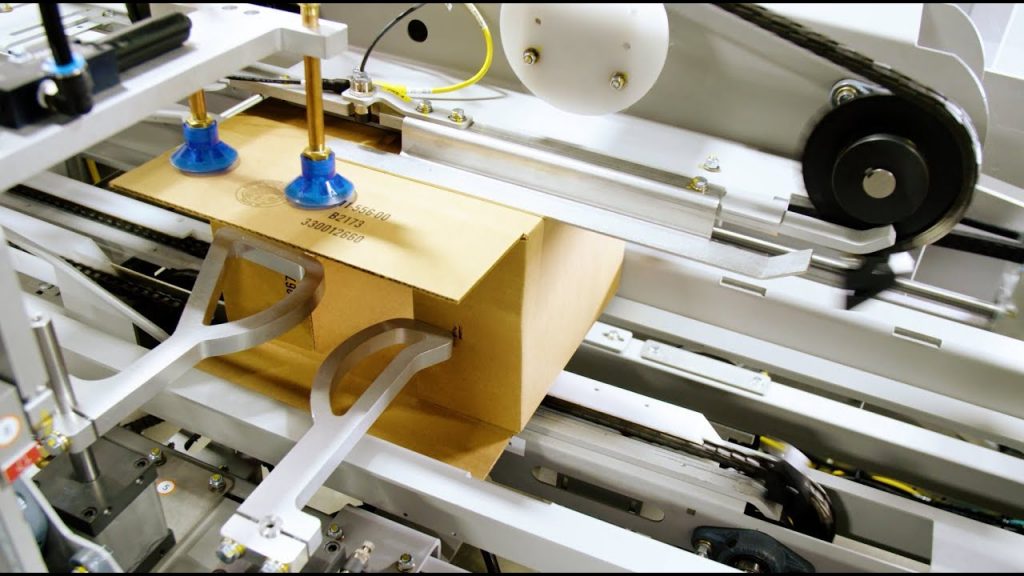

One of the key advantages of the Case Erector Machine is its ability to streamline the packaging process. Traditionally, workers would manually erect and seal cases, which is time-consuming and prone to errors. With the Case Erector Machine, this process is automated, ensuring consistent and accurate case erecting and sealing every time. This not only saves time but also eliminates the risk of product damage during packaging.

Furthermore, the Case Erector Machine is highly versatile and can handle a wide range of case sizes and styles. Whether it's a small pharmaceutical bottle or a large FMCG product, this machine can quickly and efficiently erect and seal cases of various dimensions. This flexibility is crucial for manufacturers who deal with different product sizes and packaging requirements.

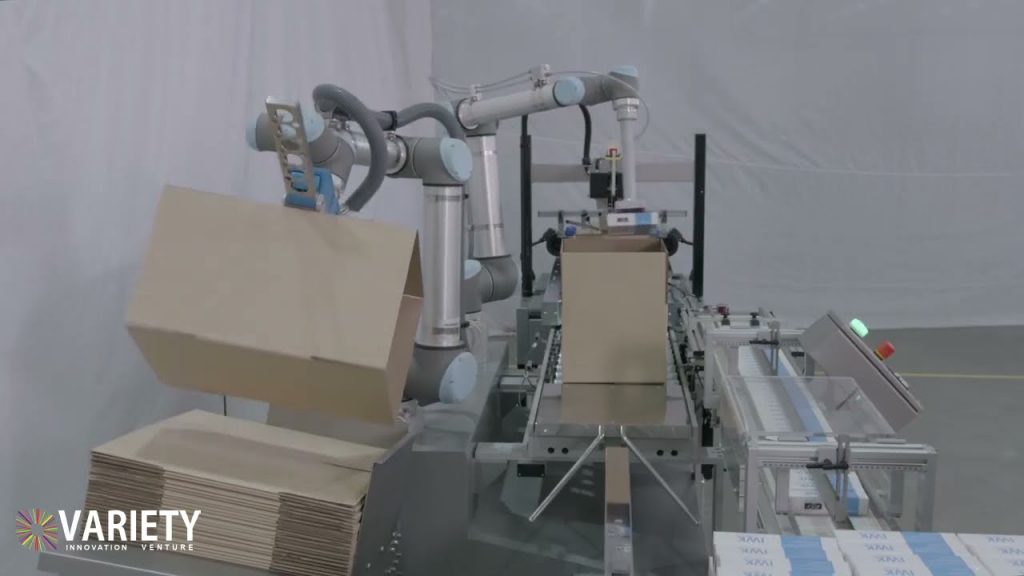

Additionally, the Case Erector Machine is equipped with advanced features such as robotic case filling and end-of-line palletizing. This means that once the cases are erected and sealed, the machine can automatically fill them with products and stack them on pallets for transportation. This not only saves time but also ensures that the products are securely packaged and ready for distribution.

The Case Erector Machine is also designed with efficiency in mind. It is equipped with state-of-the-art technology that maximizes productivity while minimizing downtime. With its high-speed operation and user-friendly interface, manufacturers can achieve higher output levels without compromising on quality.

In conclusion, the FMCG and Pharma industries require their manufacturing processes to be streamlined in order to meet the rising market demand. The Case Erector Machine is a game-changer in this regard, offering automated case erecting, sealing, filling, and palletizing functionalities. By investing in this innovative equipment, manufacturers can significantly increase their production output, reduce labor costs, and ensure consistent and efficient packaging.

If you're looking for a professional solution to optimize your packaging process, look no further than the leading manufacturers in the industry. They can provide you with the best Case Erector Machine and other packaging solutions tailored to your specific needs. Streamline your manufacturing today and stay ahead of the competition.

Check the coil packing solution with the leading manufacturer for the professional solution just here. Case Packing Machine

"Efficient and Versatile Robotic Machine for Case Erecting, Filling, and Palletizing at End of Line"