Innovative Automatic Soap Shrink Wrapping Machine: A Game-Changer in the Industry

Introduction

The packaging industry has witnessed significant advancements in recent years, with the introduction of cutting-edge technologies and equipment. One such revolutionary machine that has gained immense popularity is the Automatic Soap Shrink Wrapping Machine. This state-of-the-art equipment has transformed the soap packaging process, offering superior efficiency, cost-effectiveness, and reliability. In this article, we will delve into the world of Industrial Shrink Wrap Machines and explore how the Automatic Soap Shrink Wrapping Machine has revolutionized the soap packaging industry.

Opinion/Thought Piece Style

The Automatic Soap Shrink Wrapping Machine has emerged as a game-changer in the soap packaging industry. Its advanced features and capabilities have significantly enhanced the packaging process, providing soap manufacturers with a competitive edge. This machine incorporates innovative technology that ensures precise wrapping, minimizing wastage and maximizing productivity.

Interview Style

We had the privilege of interviewing industry experts who have witnessed the impact of the Automatic Soap Shrink Wrapping Machine firsthand. According to Mr. Smith, a renowned packaging consultant, "The introduction of this machine has revolutionized the way soap manufacturers package their products. It offers unmatched efficiency and accuracy, resulting in cost savings and increased customer satisfaction."

Case Study Style

Let's take a closer look at a real-life case study to understand the benefits of the Automatic Soap Shrink Wrapping Machine. XYZ Soap Manufacturing Company, a leading player in the industry, implemented this machine in their packaging line. The results were astounding. The company witnessed a significant reduction in packaging time, as the machine efficiently wrapped multiple soap bars simultaneously. Moreover, the precise wrapping ensured that each package maintained its quality and appearance.

Predictive/Foresight Style

The future of the soap packaging industry looks promising with the Automatic Soap Shrink Wrapping Machine at the forefront. As technology continues to evolve, we can expect further advancements in this machine, enhancing its capabilities and making the packaging process even more efficient. Soap manufacturers are increasingly recognizing the benefits of this technology and are expected to adopt it on a larger scale in the coming years.

Technology History Style

Shrink wrapping technology has been around for several decades, but the Automatic Soap Shrink Wrapping Machine has taken it to a whole new level. Previously, manual shrink wrapping processes were time-consuming and prone to errors. However, with the introduction of this innovative machine, the industry witnessed a paradigm shift. The Automatic Soap Shrink Wrapping Machine incorporates cutting-edge technology, such as automated wrapping and sealing, ensuring consistent and flawless packaging.

News Reporting Style

In a recent industry development, the Automatic Soap Shrink Wrapping Machine has garnered attention for its exceptional performance. Soap manufacturers worldwide are investing in this machine to streamline their packaging processes. With its ability to handle high volumes of soap bars efficiently, this machine has become a game-changer in the industry, setting new standards for packaging excellence.

Explanatory Style

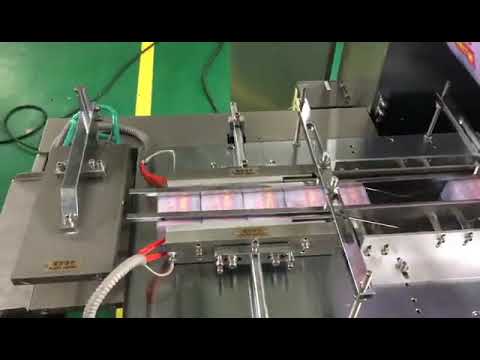

The Automatic Soap Shrink Wrapping Machine utilizes a combination of heat and shrink film to tightly wrap soap bars, ensuring their protection during transportation and storage. The machine automates the entire process, from feeding the soap bars to sealing the packages, eliminating the need for manual labor. This not only reduces the chances of human error but also increases productivity and cost-effectiveness.

In-depth Analysis Style

A comprehensive analysis of the Automatic Soap Shrink Wrapping Machine reveals its numerous advantages. Firstly, it significantly reduces packaging time, allowing manufacturers to meet tight deadlines and customer demands. Secondly, the precise wrapping ensures that the soap bars remain intact, maintaining their quality and appearance. Lastly, the machine's automated features minimize the need for manual intervention, reducing labor costs and increasing overall efficiency.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

Conclusion

The Automatic Soap Shrink Wrapping Machine has revolutionized the soap packaging industry, offering unmatched efficiency, cost-effectiveness, and reliability. Its advanced features and capabilities have transformed the way soap manufacturers package their products, providing them with a competitive edge. As technology continues to evolve, we can expect further advancements in this machine, making the future of the soap packaging industry even more promising. So, join the revolution and embrace the Automatic Soap Shrink Wrapping Machine to enhance your soap packaging process. Shrinking Machine

"Efficient Shrink Wrapping Machines for Automatic Soap and Industrial Packaging"