www.chinasuperworker.com" part with other related sentence to replace it.

Title: Revolutionizing Coil Packing with Automated Steel Coil Packing Line

Introduction:

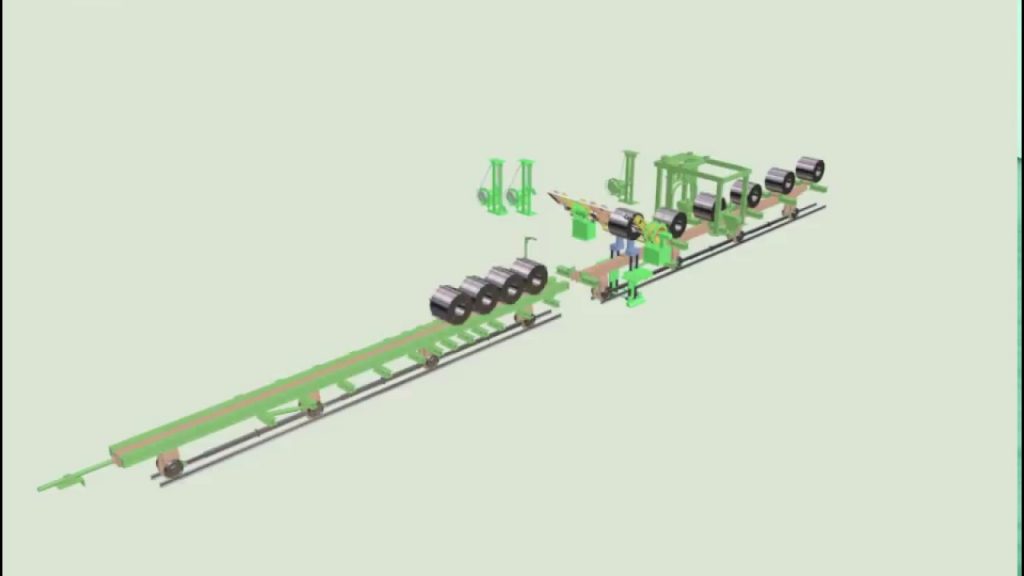

In today's fast-paced manufacturing industry, efficiency and productivity are paramount. When it comes to packaging steel coils, the traditional manual methods fall short in meeting the demands of modern production lines. This is where automated coil packing line equipment comes into play, offering a revolutionary solution to streamline the packaging process. In this article, we will explore the benefits and features of automated coil packing line equipment and how it enhances the efficiency of circumferential or radial binding.

Automated Coil Packing Line: Enhancing Efficiency and Productivity

The automated coil packing line equipment has emerged as a game-changer in the steel coil packaging industry. By automating the packaging process, it eliminates the need for manual intervention, reducing human error and increasing overall productivity. This advanced technology ensures precise and consistent wrapping, guaranteeing optimal protection for the steel coils during transportation and storage.

Benefits of Automated Coil Packing Line:

1. Improved Efficiency: With automated coil packing line equipment, the packaging process becomes faster and more efficient. This allows manufacturers to meet tight production deadlines and deliver high-quality products to their customers on time.

2. Enhanced Safety: Manual coil packing can be a labor-intensive and potentially hazardous task. By automating the process, the risk of injuries to workers is significantly reduced, ensuring a safer working environment.

3. Consistent Packaging: Automated coil packing line equipment ensures consistent wrapping tension, preventing loose or uneven packaging. This consistency not only enhances the overall appearance of the packaged coils but also provides better protection against external factors such as moisture and dust.

4. Cost Savings: By reducing the reliance on manual labor, automated coil packing line equipment helps companies save on labor costs. Additionally, the consistent packaging ensures minimal material wastage, resulting in cost savings over time.

Features of Automated Coil Packing Line:

1. Advanced Control System: The automated coil packing line comes equipped with an advanced control system that allows for easy operation and monitoring of the packaging process. This system ensures precise control over wrapping tension, speed, and other parameters, guaranteeing optimal packaging quality.

2. Customizable Packaging Options: The automated coil packing line can be customized to meet specific packaging requirements. Whether it's circumferential or radial binding, the equipment offers versatile packaging options, accommodating different coil sizes and shapes.

3. Integration with Existing Production Lines: The automated coil packing line can seamlessly integrate with existing production lines, ensuring a smooth transition from manufacturing to packaging. This integration eliminates bottlenecks and optimizes the overall production process.

Conclusion:

Automated coil packing line equipment has revolutionized the steel coil packaging industry by offering enhanced efficiency, improved safety, consistent packaging, and cost savings. With its advanced control system and customizable packaging options, this equipment proves to be a valuable investment for manufacturers. Check a leading manufacturer for the professional solution and witness the transformation in your coil packing process.

Rewrite the last section:

Discover the perfect coil packing solution with a trusted industry leader who specializes in providing professional packaging equipment. Explore the range of innovative solutions available to optimize your coil packaging process and elevate your production efficiency. Coil packing Line

"Efficient and Versatile Steel Coil Packing Line: Revolutionizing Circumferential and Radial Binding Processes with Automation"