Labeling Machine - A Game-Changer in the Packaging Industry

Introduction:

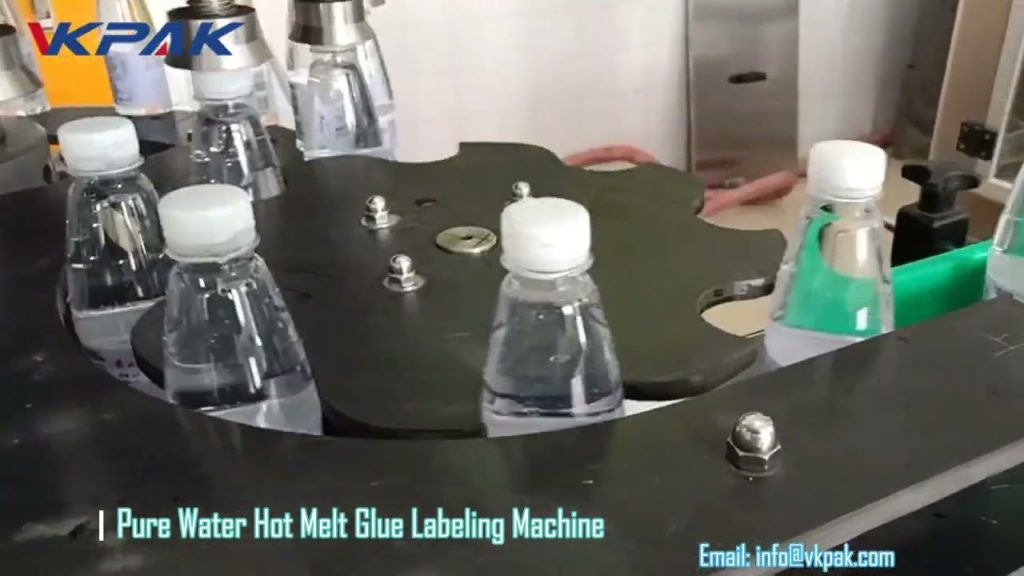

In the fast-paced world of the packaging industry, efficiency and accuracy are key factors in ensuring the success of any business. One crucial aspect of packaging is labeling, which not only provides essential information but also serves as a branding tool. To meet the demands of this industry, a hot melt glue labeling machine for water bottles has emerged as a game-changer. In this article, we will delve into the features, benefits, and working principles of this revolutionary labeling machine.

The Evolution of Labeling Machines:

Labeling machines have come a long way since their inception. From manual labeling to semi-automatic and now fully automated systems, the industry has witnessed a remarkable transformation. Among the various types of labeling machines available, the hot melt glue labeling machine for water bottles stands out for its efficiency and versatility.

Working Principle:

The hot melt glue labeling machine utilizes a hot melt adhesive to apply labels to water bottles. It works by melting a solid adhesive and applying it to the label. When the label comes in contact with the bottle, the adhesive quickly solidifies, ensuring a strong and long-lasting bond. This method eliminates the need for water or solvent-based adhesives, making it an environmentally friendly choice.

Features and Benefits:

1. High Speed and Accuracy: The hot melt glue labeling machine can label a large number of bottles in a short span of time without compromising on accuracy. This increases productivity and reduces labor costs.

2. Versatility: This labeling machine is designed to handle various bottle shapes and sizes, making it suitable for a wide range of products. It can accommodate both round and square bottles, making it a versatile solution for packaging needs.

3. Cost-Effective: By automating the labeling process, businesses can significantly reduce labor costs. Additionally, the hot melt glue labeling machine eliminates the need for costly consumables such as water or solvent-based adhesives.

4. Durability: The hot melt adhesive used in this labeling machine ensures that the labels adhere firmly to the bottles, even under challenging conditions such as high humidity or temperature variations. This durability ensures that the labels remain intact throughout the product's lifecycle.

5. Ease of Use and Maintenance: These labeling machines are designed for user-friendly operation. With minimal training, operators can efficiently handle the machine, reducing downtime and increasing overall productivity. Additionally, routine maintenance is simple, ensuring uninterrupted operation.

Conclusion:

The hot melt glue labeling machine for water bottles has revolutionized the packaging industry. Its speed, accuracy, versatility, and cost-effectiveness make it an ideal choice for businesses looking to streamline their labeling processes. With its ability to handle various bottle shapes and sizes, this machine offers a flexible solution for packaging needs. Furthermore, the durability of hot melt adhesive ensures that labels remain intact, even under challenging conditions. Embracing this technology will undoubtedly propel businesses to new heights of efficiency and success.

Check the coil packing solution with a leading manufacturer for a professional solution just here. Labeling Machine

"Efficient Labeling Solutions for Water Bottles: Hot Melt Glue Labeling Machine and More"