Looking for the best shrink packaging machine? Look no further! In this article, we will guide you through the ins and outs of shrink packaging machines, including how to insert film for our shrink wrapping machine, shrink wrapper, POF/PE film L type sealer. So, let's dive right in!

Shrink packaging machines have revolutionized the packaging industry by providing a cost-effective and efficient way to pack products. These machines use heat to shrink a plastic film around a product, creating a tight and secure package. They are widely used in industries such as food and beverage, pharmaceuticals, electronics, and many more.

One of the key factors that determine the effectiveness of a shrink packaging machine is the type of film used. POF (Polyolefin) and PE (Polyethylene) films are the most commonly used films in shrink packaging. POF films offer excellent clarity, durability, and resistance to tears, making them ideal for packaging products that require high visibility. On the other hand, PE films are known for their flexibility and are often used for wrapping irregularly shaped products.

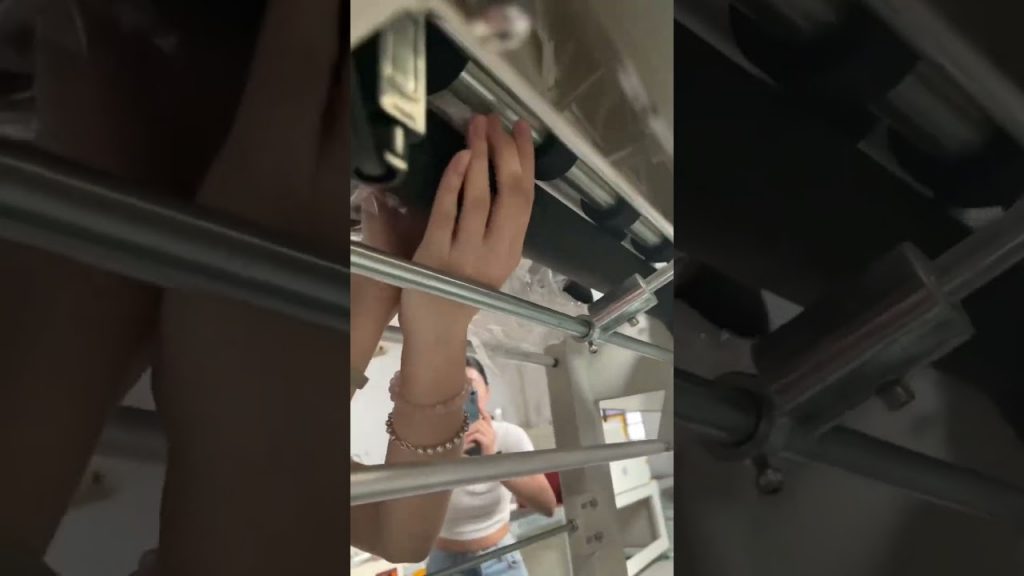

Now, let's talk about how to insert film for our shrink wrapping machine. The process may vary slightly depending on the specific machine, but the basic steps remain the same. Here's a step-by-step guide:

1. Start by ensuring that the machine is properly set up and ready for operation. Make sure that all safety precautions are in place.

2. Take the roll of film and place it on the film holder or spindle of the machine. Make sure that the film is aligned properly and that it unwinds smoothly.

3. Thread the film through the various rollers and guides of the machine, following the manufacturer's instructions. It is important to pay attention to the correct path of the film to avoid any issues during the packaging process.

4. Once the film is threaded through the machine, adjust the tension settings to ensure that the film is pulled tightly around the product during the shrinking process. This will help create a neat and professional-looking package.

5. Test the machine by running a few sample products through it. This will help you fine-tune the settings and ensure that the film is applied correctly.

Now that you have a better understanding of shrink packaging machines and how to insert film, let's take a look at some of the benefits they offer:

1. Improved Product Protection: Shrink packaging provides a tight and secure seal around the product, protecting it from moisture, dust, and other contaminants.

2. Enhanced Product Presentation: Shrink-wrapped products have a neat and professional appearance, making them more appealing to customers.

3. Increased Efficiency: Shrink packaging machines can package products at a much faster rate compared to manual methods, improving overall productivity.

4. Cost Savings: By automating the packaging process, shrink packaging machines help reduce labor costs and minimize material waste.

In conclusion, shrink packaging machines are a game-changer in the packaging industry. They offer a cost-effective and efficient way to package products while ensuring superior product protection and presentation. By following the steps mentioned above, you can easily insert film for our shrink wrapping machine and enjoy the benefits of shrink packaging. So, what are you waiting for? Check out our coil packing solution and experience the professional packaging solution you deserve!

Check the coil packing solution with a leading manufacturer for the professional solution just here. Shrinking Machine

"Efficient Film Insertion for Shrink Wrapping Machines: A Comprehensive Guide to POF/PE Film, L Type Sealers, and Shrink Packaging Machines"