Pallet Strapping Machine: Enhancing Efficiency and Safety in Packaging

In today's fast-paced business world, optimizing packaging processes is crucial for companies to stay competitive. One key component in achieving this is the Pallet Strapping Machine, a powerful tool that simplifies and accelerates the strapping process, resulting in enhanced efficiency and safety.

A pallet strapping machine is a device designed to secure goods to a pallet by applying a strap or band around them. This process ensures that the products remain intact and stable during transportation, reducing the risk of damage, loss, or accidents. By automating the strapping process, businesses can save valuable time and resources, allowing them to focus on other core aspects of their operations.

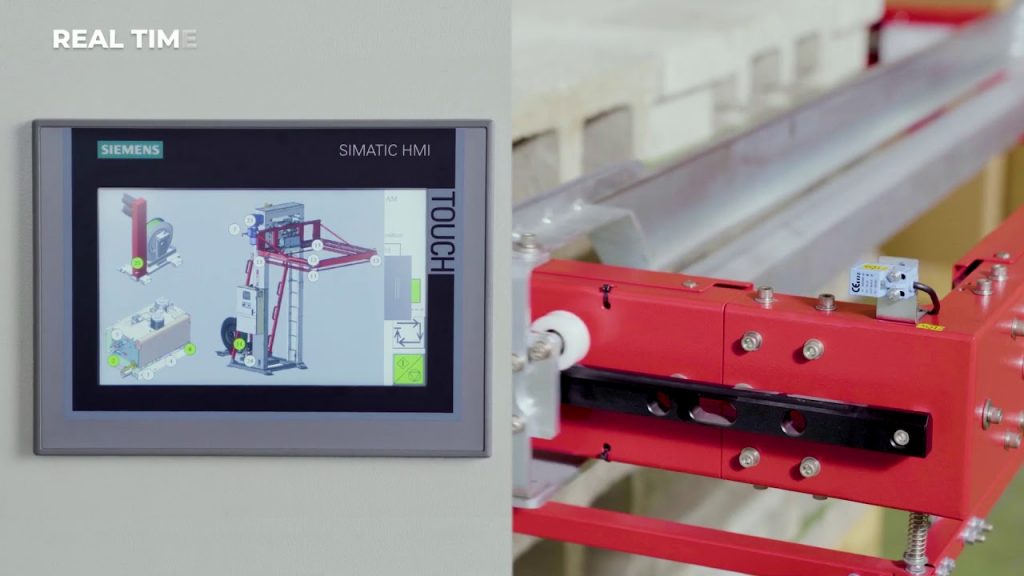

One popular type of pallet strapping machine is the Horizontal Pallet Strapping Machine. This fully automatic strapping machine offers advanced features that improve efficiency and productivity. With its user-friendly interface and intuitive controls, even operators with minimal training can operate the machine with ease. The automatic tensioning and sealing functions ensure consistent and reliable strapping results, eliminating human errors and minimizing waste.

The Horizontal Pallet Strapping Machine is equipped with state-of-the-art technology to handle various strapping materials and work with different pallet sizes. It can efficiently strap products made of materials such as plastic, polyester, or steel, providing flexibility and adaptability to diverse packaging needs. Additionally, this machine can accommodate pallets of different heights, widths, and lengths, making it suitable for a wide range of industries and applications.

With safety being a top priority in any workplace, the Horizontal Pallet Strapping Machine incorporates several safety features to protect operators and prevent accidents. These include emergency stop buttons, safety sensors, and protective guards. By minimizing the risks associated with manual strapping, businesses can provide a safer working environment for their employees while maintaining high productivity levels.

Investing in a pallet strapping machine offers numerous benefits for businesses. Firstly, it significantly reduces labor costs by eliminating the need for manual strapping, allowing workers to focus on more value-added tasks. The machine's high strapping speed and continuous operation capability also contribute to improved productivity. Moreover, the consistent and secure strapping provided by the machine ensures that products reach their destination intact, reducing the likelihood of customer complaints and returns.

When considering a pallet strapping machine for your packaging operations, it is crucial to choose a reputable and reliable manufacturer. Look for a company that specializes in coil packing solutions and has a proven track record in the industry. By partnering with a leading manufacturer, you can access professional solutions tailored to your specific needs and benefit from their expertise and support.

In conclusion, a pallet strapping machine is a valuable asset for businesses aiming to optimize their packaging processes. Whether you choose a Horizontal Pallet Strapping Machine or another type, it is essential to select a machine that meets your requirements and is designed to enhance efficiency and safety. By investing in this advanced technology, you can streamline your operations, reduce costs, and ensure that your products are delivered to customers in perfect condition.

Check out our leading manufacturer for the professional pallet strapping machine solution. They offer a wide range of reliable and innovative coil packing solutions that can meet your unique packaging needs. Visit their website now to explore their comprehensive range of products and achieve optimal efficiency in your packaging operations. Strapping Machines

"Efficiently Secure Pallets with a Fully Automatic Horizontal Strapping Machine"