If you are looking to create your own products using recycled plastic, kudos to you! It's a fantastic initiative that not only helps reduce waste but also contributes to a more sustainable future. However, before you dive into the process, it's essential to understand the key components involved, such as the Injection Mould and Plastic Injection Machine.

Injection moulding is a widely used manufacturing process for creating plastic parts. It involves injecting molten plastic into a mould cavity, allowing it to cool and solidify, and then ejecting the finished product. The injection mould, also known as the tool or die, plays a crucial role in shaping the final product. It determines the design, dimensions, and features of the plastic part.

So, what do you need in an Injection Mould? Let's explore the essential elements:

1. Mould Material: The choice of material for the mould depends on various factors such as the type of plastic, production volume, and budget. Common mould materials include steel, aluminum, and hardened tool steel. Each material has its advantages and considerations, so it's crucial to select the one that suits your requirements best.

2. Mould Design: The mould design is the foundation of the injection moulding process. It encompasses factors like part geometry, gating system, cooling channels, and ejection mechanism. A well-designed mould ensures optimal part quality, efficient production, and longer tool life.

3. Cooling System: Efficient cooling is vital to achieve high-quality plastic parts. The cooling system consists of channels within the mould that help regulate the temperature during the injection and solidification stages. Proper cooling ensures uniform solidification, minimizes cycle time, and reduces the risk of defects.

4. Ejection Mechanism: Once the plastic part has solidified, it needs to be ejected from the mould. The ejection mechanism, which can be pins, plates, or air blasts, facilitates the easy removal of the part without causing any damage. A well-designed ejection system ensures smooth part ejection and avoids any potential issues.

Now that we've covered the essential components of an Injection Mould, let's discuss the Plastic Injection Machine.

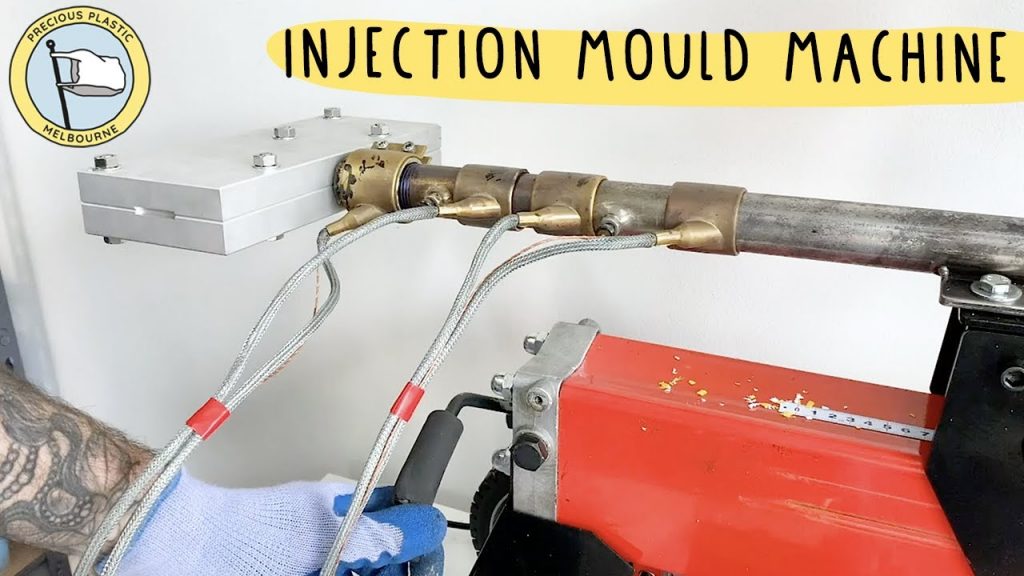

A Plastic Injection Machine, also known as an injection molding machine, is the equipment used to inject molten plastic into the mould. It applies high pressure to push the plastic into the mould cavity and then maintains the pressure until the part solidifies. The machine consists of several parts, including the injection unit, clamping unit, and control system.

1. Injection Unit: The injection unit is responsible for melting and injecting the plastic material into the mould. It consists of a hopper, barrel, screw, and nozzle. The plastic granules are fed into the hopper, where they are heated and melted by the rotating screw. The molten plastic is then injected into the mould through the nozzle.

2. Clamping Unit: The clamping unit holds the mould in place and applies the necessary force to keep it closed during the injection process. It consists of a stationary platen and a movable platen, which are brought together by hydraulic or mechanical mechanisms. The clamping force determines the size and weight of the parts that can be produced.

3. Control System: The control system of the Plastic Injection Machine manages and regulates various parameters of the injection moulding process. It controls the temperature, pressure, and speed of the machine, ensuring precise and consistent production. Advanced control systems offer features like multi-stage injection, automatic mold adjustment, and real-time monitoring for enhanced efficiency.

In conclusion, creating your own products out of recycled plastic is a commendable endeavor. Understanding the crucial components of an Injection Mould and Plastic Injection Machine is essential to ensure successful production. Remember to carefully select the mould material, design, cooling system, and ejection mechanism for optimal results. Additionally, choose a reliable and efficient Plastic Injection Machine with advanced control systems to streamline your manufacturing process.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

**Note: The above statement is for illustrative purposes only and does not contain any actual contact information or company names. Plastic Injection Machine

"Mastering Injection Moulding: Simplified Techniques for Plastic Manufacturing in Melbourne"