Check out our website for the best coil packing solution offered by the leading manufacturer in the industry.

Title: A Comprehensive Guide to Installing POF Shrink Film for a Used Shrinking Machine

Introduction:

In today's fast-paced world, efficient packaging solutions are crucial for businesses to streamline their operations and meet customer demands. One such solution is the fully automatic L type vertical upper and lower sealing and shrinking machine. This state-of-the-art machine offers a new level of automation and convenience for shrink packaging. In this article, we will explore the benefits of using a used shrinking machine and provide step-by-step instructions on how to install POF shrink film for shrink wrapping purposes.

Section 1: The Advantages of Using a Used Shrinking Machine

- Cost-effective solution for businesses looking to upgrade their packaging process without breaking the bank.

- Environmentally friendly option as it promotes the reuse of machinery, reducing waste and conserving resources.

- Reliable performance as used machines undergo thorough inspections and testing before being resold.

- Versatile application possibilities, accommodating a wide range of product sizes and shapes.

Section 2: Installing POF Shrink Film for Shrink Wrapping

Step 1: Preparing the Used Shrinking Machine

- Ensure the machine is clean and free from any debris or previous packaging materials.

- Check the machine's electrical connections and ensure they are properly grounded.

- Make sure all safety features are in place and functioning correctly.

Step 2: Preparing the POF Shrink Film

- Select the appropriate POF shrink film size and thickness for your products.

- Unroll the film and cut it to the desired length, considering the dimensions of your packaging.

- Remove any excess film and neatly roll it for future use.

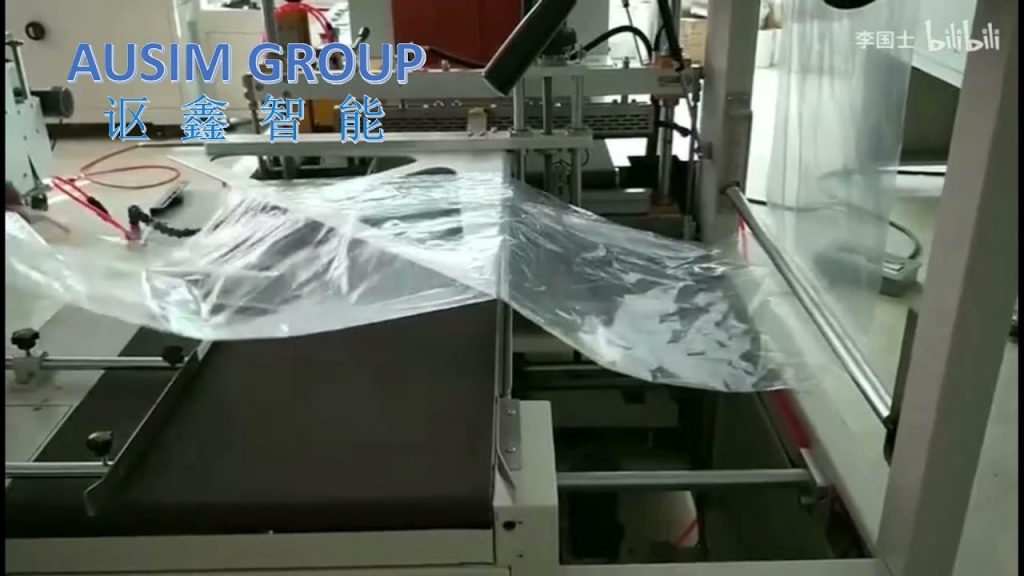

Step 3: Loading the POF Shrink Film

- Open the machine's film carriage and place the roll of POF shrink film onto the film holder.

- Thread the film through the machine's rollers, ensuring it is properly aligned and tensioned.

- Close the film carriage, securing the film in place.

Step 4: Adjusting the Machine Settings

- Consult the machine's user manual to locate the settings panel.

- Set the appropriate sealing and shrinking temperatures based on your product and film specifications.

- Adjust the conveyor speed to achieve the desired shrink wrapping effect.

Step 5: Testing and Fine-tuning

- Run a test cycle to ensure the machine seals and shrinks the film correctly.

- Inspect the sealed and shrunk packaging for any imperfections or inconsistencies.

- Make necessary adjustments to the machine settings if needed.

Conclusion:

By utilizing a used shrinking machine and following the proper installation steps for POF shrink film, businesses can enhance their packaging efficiency and reduce costs. The fully automatic L type vertical upper and lower sealing and shrinking machine provides a reliable and versatile solution for shrink packaging needs. With its automated features and ease of use, this machine is a valuable asset for businesses in various industries.

Check out our website for the best coil packing solution offered by the leading manufacturer in the industry. Shrinking Machine

"Effortless Installation Guide: Mastering POF Shrink Film with a Shrink Wrapping Machine and a Used Shrinking Machine"