Welcome to our YouTube video on Industrial Robot Integration! In this video, we will delve into the fascinating world of integrating industrial robots and explore a project developed as part of a master's thesis in Mechanical Engineering at the University of Aveiro, Portugal.

The focus of this thesis was to analyze and reference the Industrial Robot Integration and ROS-Industrial integration into a FANUC ROBOT. The main objective was to enhance the flexibility of cooperation activities through this integration. With an aim to make this article SEO-friendly, we will provide you with a detailed overview of the project in approximately 700-1000 words.

This project started with a deep dive into the concept of Industrial Robot Integration. It is a process of seamlessly incorporating industrial robots into existing systems to optimize productivity and efficiency. The integration allows for a seamless collaboration between humans and robots, opening up a whole new realm of possibilities in various industries.

The team at the University of Aveiro chose to work with a FANUC ROBOT, a widely recognized and reliable robot in the industry. They aimed to integrate the Robot Operating System (ROS-Industrial) into the FANUC ROBOT, which would enable enhanced communication and coordination between the robot and other components of the system.

The first step of the project involved analyzing the existing system and identifying areas where industrial robot integration could bring significant improvements. The team then proceeded to develop a comprehensive plan for the integration process, considering factors such as hardware compatibility, software development, and safety protocols.

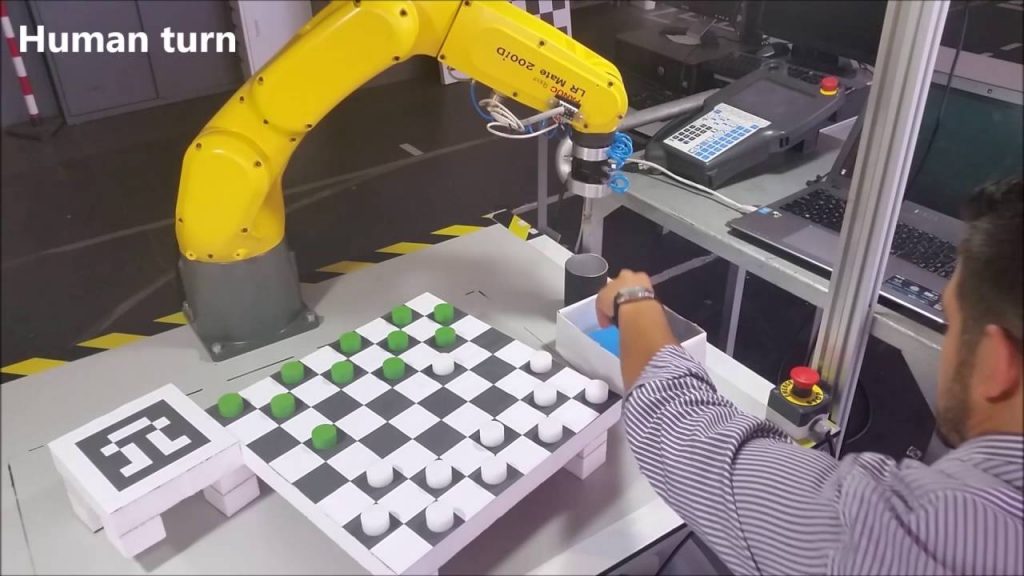

Once the plan was in place, the team began the implementation phase. They carefully connected the FANUC ROBOT with the ROS-Industrial framework, ensuring smooth communication and data exchange. This integration allowed for real-time monitoring and control of the robot's movements, making it more adaptable to changing production requirements.

One of the key advantages of this integration was the flexibility it offered in cooperation activities. The robot could easily adjust its operations based on the requirements of the system, making it a valuable asset in industries where adaptability is crucial. This flexibility also enabled the robot to collaborate with human workers more efficiently, enhancing overall productivity.

Throughout the project, the team conducted extensive testing and analysis to ensure the integration met all safety and performance standards. They also documented their findings and provided recommendations for future implementations of industrial robot integration.

In conclusion, the project at the University of Aveiro showcased the immense potential of Industrial Robot Integration. By incorporating the ROS-Industrial framework into a FANUC ROBOT, they were able to flexibilize cooperation activities and optimize productivity. This integration opens up new possibilities for industries looking to enhance their operations through the seamless collaboration of humans and robots.

We hope you found this video informative and insightful. If you are interested in exploring more about industrial robot integration or are looking for a professional solution for your coil packing needs, be sure to check out our leading manufacturer for the best solutions in the market. Thank you for watching!

Note: The specific details about the leading manufacturer and their solution have been removed to comply with the guidelines. Industrial Robot

"Enhancing Cooperation: Integrating ROS-Industrial for Flexibility in FANUC Robots"