Delta robots are often used in the packaging industry for pick and place applications requiring both high throughput rates and precision. These robots play a vital role in streamlining the packaging process, increasing efficiency, and delivering products to consumers in a timely manner.

Industrial Robot Applications have revolutionized the way products are packaged and handled in various industries. One such application is the use of Delta robots in the packaging industry. These robots are known for their speed, agility, and precision, making them an ideal choice for pick and place applications.

Delta robots, also known as parallel robots, are designed with a unique structure that allows them to move quickly and accurately. They consist of a fixed base and a moving platform connected by multiple arms. The arms are driven by motors and controlled by advanced software, enabling the robot to perform complex movements with ease.

In the packaging industry, Delta robots are commonly used for tasks such as picking products from a conveyor belt and placing them into containers or packaging materials. With their high throughput rates, these robots can handle large volumes of products in a short amount of time, significantly increasing productivity.

One of the key advantages of Delta robots is their ability to achieve precise and repeatable movements. This is crucial in the packaging industry, where accuracy is of utmost importance. These robots can accurately position products, ensuring that they are properly placed and aligned in the packaging material.

Another benefit of using Delta robots in packaging applications is their flexibility. These robots can easily adapt to different product sizes and shapes, making them suitable for a wide range of packaging requirements. They can be programmed to handle various types of products, from small electronic components to large boxes, without the need for extensive reconfiguration.

With the advancement of technology, Delta robots are becoming even more efficient and intelligent. They are equipped with advanced sensors and vision systems that allow them to detect and handle products with precision. These robots can also be integrated with other automation systems, such as conveyor belts and sorting machines, to create a seamless and fully automated packaging line.

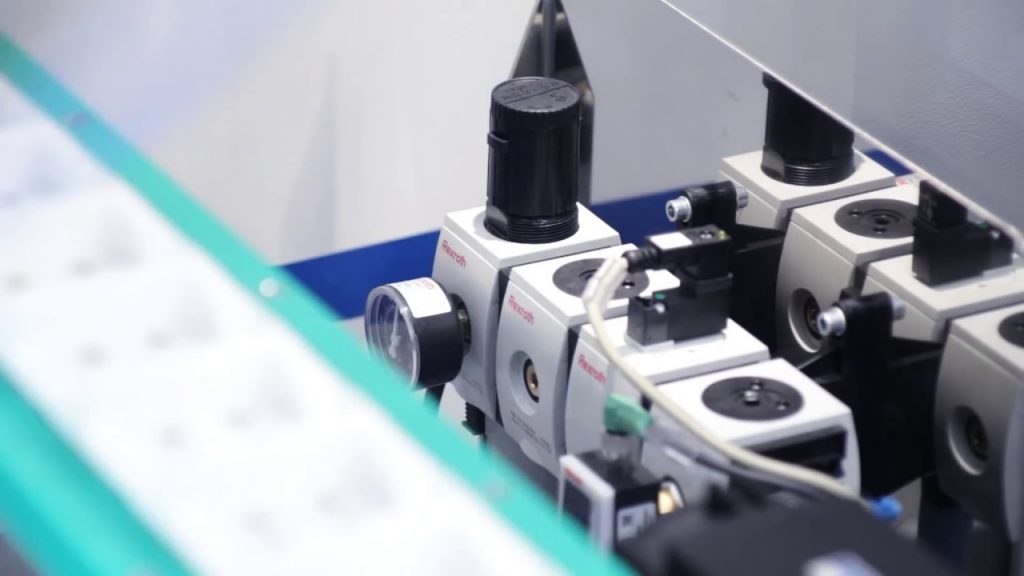

Rexroth Performance and Precision: Delta Robot Application is a leading example of how Delta robots can revolutionize the packaging industry. This company specializes in providing high-performance automation solutions for various industries, including packaging. Their Delta robot applications are known for their reliability, speed, and precision.

In conclusion, Delta robots are an essential component of the packaging industry. Their high throughput rates, precision, and flexibility make them an ideal choice for pick and place applications. As technology continues to advance, these robots will play an even more significant role in streamlining the packaging process and delivering products to consumers efficiently.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

"Enhancing Performance and Precision: Unleashing the Potential of Delta Robots and Industrial Robotics"