Check out the leading manufacturer for professional coil packing solutions here:

Are you in the manufacturing industry and looking to streamline your part inspection process? Look no further! Sawyer, the innovative robot from Rethink Robotics, has introduced new vision system capabilities that can automate part inspection with ease. In this article, we will explore how industrial robot technology, coupled with intelligent vision systems, is revolutionizing industrial robotic automation.

Industrial Robot Technology: A Game-Changer in Manufacturing

Industrial robot technology has been a game-changer in the manufacturing industry. These robots are designed to perform repetitive tasks with precision, speed, and accuracy, reducing human error and increasing productivity. With advancements in technology, these robots have become even more versatile and efficient, catering to a wide range of applications.

Sawyer: Redefining Automation with Vision System Capabilities

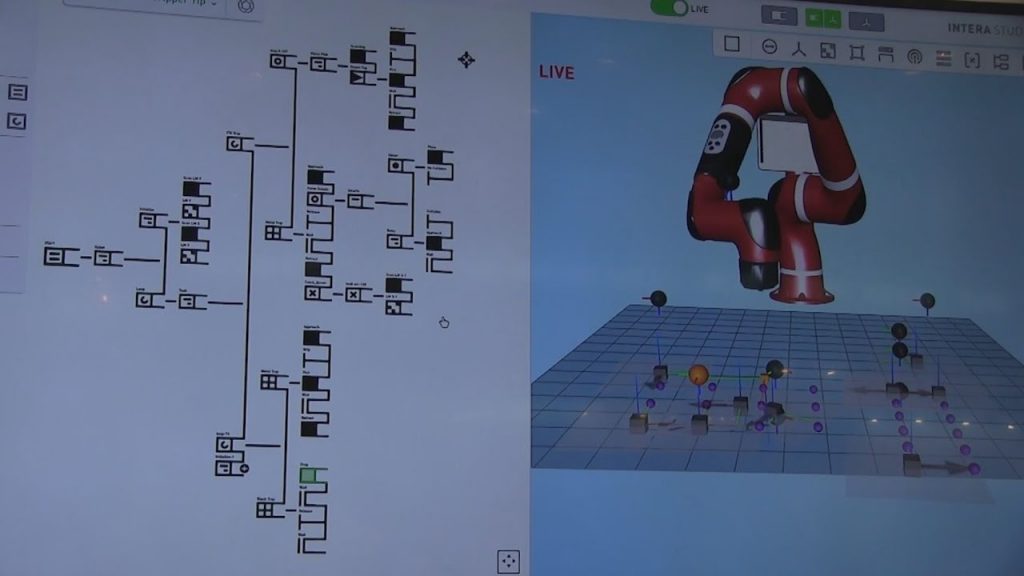

Rethink Robotics' Sawyer is a collaborative robot that has taken automation to the next level. With its new vision system capabilities, Sawyer can now inspect parts with high accuracy, ensuring quality control throughout the production process. This intelligent vision system enables the robot to identify defects, measure dimensions, and perform intricate inspections with ease.

Intelligent Vision Systems: Enhancing Robotic Automation

Intelligent vision systems play a crucial role in enhancing industrial robotic automation. These systems utilize advanced algorithms and sensors to analyze visual data and make informed decisions. By integrating vision systems into robots like Sawyer, manufacturers can achieve higher levels of automation, improved efficiency, and reduced costs.

Improved Quality Control: Preventing Defects and Reducing Waste

One of the key benefits of employing Sawyer's vision system capabilities is improved quality control. The robot can identify defects in real-time, preventing faulty parts from proceeding further in the production line. By catching defects early on, manufacturers can minimize waste, reduce rework, and ensure that only high-quality products reach the market.

Efficient Inspection Process: Saving Time and Resources

Automating the part inspection process with Sawyer's vision system capabilities saves manufacturers valuable time and resources. The robot can perform inspections at a much faster rate compared to manual inspections, thereby increasing overall productivity. Additionally, the robot's ability to work continuously without fatigue ensures consistent and reliable inspection results.

Flexibility and Adaptability: Meeting Changing Production Demands

Industrial robot technology, coupled with intelligent vision systems, offers unparalleled flexibility and adaptability in meeting changing production demands. Sawyer can be easily reprogrammed to perform different inspection tasks, allowing manufacturers to quickly adapt to new product lines or changing quality requirements. This flexibility ensures that businesses stay competitive in today's dynamic manufacturing landscape.

The Future of Industrial Robotic Automation

As technology continues to advance, the future of industrial robotic automation looks promising. Intelligent vision systems, like the one found in Sawyer, will continue to evolve, enabling robots to perform even more complex inspection tasks. The integration of artificial intelligence and machine learning algorithms will further enhance the decision-making capabilities of these robots, making them even more efficient and autonomous.

In conclusion, Sawyer from Rethink Robotics, with its new vision system capabilities, is revolutionizing the part inspection process in the manufacturing industry. Industrial robot technology, coupled with intelligent vision systems, offers improved quality control, efficient inspection processes, and flexibility in meeting changing production demands. As we look towards the future, the possibilities for industrial robotic automation are endless.

Check out the leading manufacturer for professional coil packing solutions here: Industrial Robot

"Enhancing Industrial Robot Automation with Intelligent Vision Systems: Revolutionizing Robot Technology"