Productive and Safe Interaction Between Humans and KUKA Robots

Introduction:

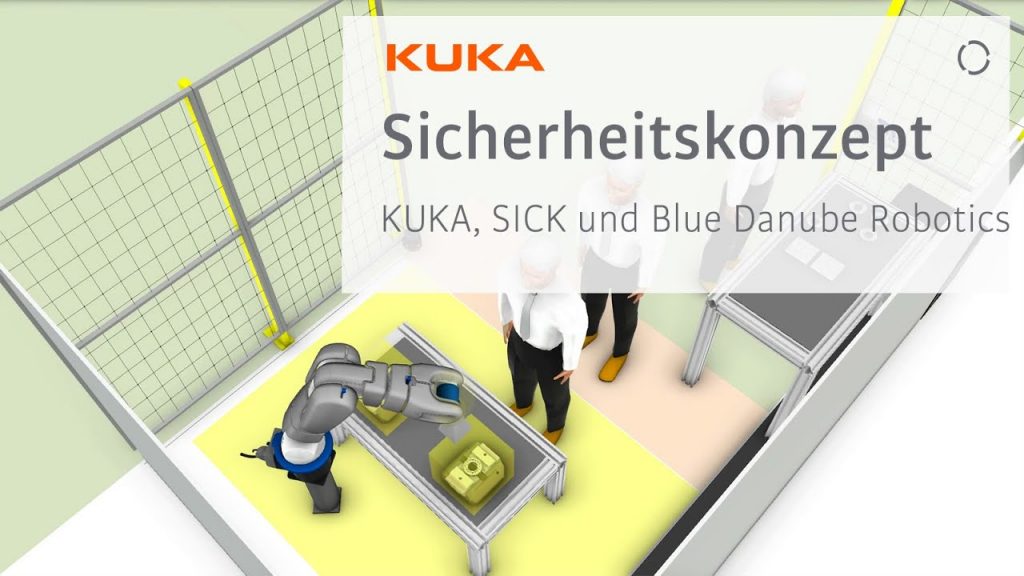

In today's rapidly evolving industrial landscape, the collaboration between humans and robots has become increasingly common. KUKA, in partnership with SICK and Blue Danube Robotics, offers a revolutionary solution that ensures both productivity and safety in human-robot interactions. With a focus on Industrial Robot Safety, this article will discuss the concept of safety for industrial robots and the measures taken by KUKA to ensure a secure working environment.

Industrial Robot Safety: An Analytical Perspective

Safety is paramount when it comes to human-robot collaboration in industrial settings. The risk of accidents and injuries can be significantly reduced by implementing effective safety measures. KUKA recognizes the importance of Industrial Robot Safety and has taken proactive steps to address this concern.

KUKA's Safety Concept for Industrial Robots

KUKA's safety concept revolves around providing comprehensive solutions that enable safe and efficient human-robot collaboration. This concept encompasses various aspects, including safety sensors, motion control, and intelligent software.

Safety Sensors: The Key to Safe Interaction

Safety sensors play a vital role in ensuring a safe working environment. These sensors detect the presence of humans within the robot's workspace and trigger appropriate actions to prevent collisions and accidents. By integrating advanced safety sensors, KUKA ensures that their robots can detect and respond to human presence with great accuracy and reliability.

Motion Control: Precise and Safe Robot Movements

Precise motion control is crucial to prevent accidental collisions between humans and robots. KUKA's robots are equipped with advanced motion control systems that allow for smooth and controlled movements. This ensures that the robots can work alongside humans without compromising safety.

Intelligent Software: Enhancing Safety and Efficiency

KUKA's intelligent software plays a crucial role in optimizing the interaction between humans and robots. This software enables the robots to adapt their behavior based on the surrounding environment and the presence of humans. By analyzing real-time data from safety sensors, KUKA's robots can make informed decisions to ensure safe and efficient collaboration.

Case Study: A Real-life Example of Safe Human-Robot Interaction

To further illustrate the effectiveness of KUKA's safety concept, let's consider a case study. In a manufacturing facility, KUKA robots are employed to assist human workers in assembly tasks. The robots are equipped with safety sensors that continuously monitor the workspace. If a human worker enters the robot's vicinity, the sensors detect their presence and instantly trigger a response. The robot slows down its movements or comes to a complete stop to avoid any potential collision. Once the human worker leaves the workspace, the robot resumes its tasks, ensuring a seamless and safe collaboration.

Conclusion:

KUKA, in collaboration with SICK and Blue Danube Robotics, offers a comprehensive solution for productive and safe interaction between humans and robots. By prioritizing Industrial Robot Safety, KUKA ensures that their robots can work seamlessly alongside human workers, minimizing the risk of accidents and injuries. With advanced safety sensors, precise motion control, and intelligent software, KUKA's robots set a benchmark for safety in industrial settings.

Check the coil packing solution with a leading manufacturer for a professional solution just here. Industrial Robot

"Ensuring Safety in Industrial Robotics: Vital Measures for Protecting Workers and Enhancing Workplace Security"