Title: Industrial Packing Line - Changeover Solutions for Pharmaceutical Production Machinery

Description:

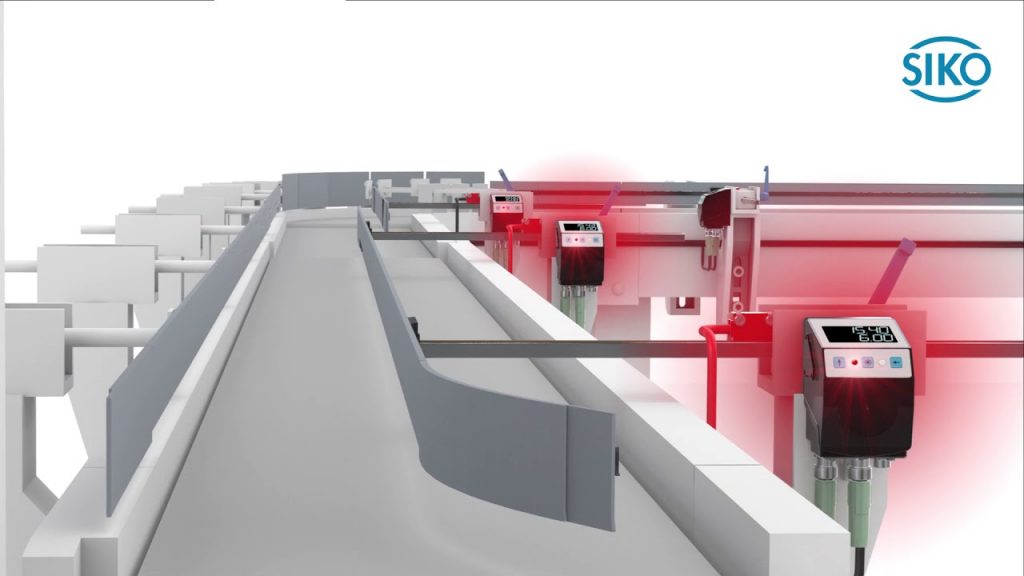

Welcome to our informational video on the Industrial Packing Line and its Changeover Solutions for Pharmaceutical Production Machinery. In this video, we delve into the crucial aspect of traceability for pharma and packaging, highlighting the importance of inspection, transport, and track & trace in machines specifically designed for pharmaceutical production.

Introduction:

In this highly informative video, we explore the Industrial Packing Line and its Changeover Solutions for Pharmaceutical Production Machinery. We will provide you with a comprehensive overview of the key features and benefits of this cutting-edge technology, ensuring you gain a solid understanding of its significance in the pharmaceutical industry.

Video Content:

Our video covers a wide range of topics related to the Industrial Packing Line and its Changeover Solutions for Pharmaceutical Production Machinery. We start by explaining the concept of traceability and its role in the pharma and packaging sectors. With an emphasis on inspection, transport, and track & trace processes, we showcase how these solutions optimize pharmaceutical production.

Key Highlights:

1. Streamlined Changeover Solutions: Discover how our Industrial Packing Line offers efficient changeover solutions, minimizing downtime and increasing productivity in pharmaceutical production machinery.

2. Traceability for Pharma & Packaging: Learn about the importance of traceability in the pharmaceutical industry, ensuring product safety, quality control, and regulatory compliance.

3. Inspection: Explore the integral role of inspection in pharmaceutical production machinery, ensuring the accuracy and integrity of each product.

4. Transport: Understand the significance of optimized transport systems within the Industrial Packing Line, facilitating smooth and efficient movement of pharmaceutical products.

5. Track & Trace: Gain insights into how track & trace technology enhances supply chain transparency, combating counterfeiting and ensuring product authenticity.

Call to Action:

If you found our video on the Industrial Packing Line and its Changeover Solutions for Pharmaceutical Production Machinery informative, please consider liking, subscribing, and sharing with others who may benefit from this valuable content.

Additional Tags and Keywords: industrial packing line, changeover solutions, pharmaceutical production machinery, traceability, inspection, transport, track & trace, pharma, packaging, efficiency, productivity, supply chain transparency, product safety, quality control, regulatory compliance.

Hashtags: #IndustrialPackingLine #ChangeoverSolutions #PharmaceuticalProduction #Traceability #PharmaPackaging #Inspection #Transport #TrackandTrace #ProductSafety #QualityControl #SupplyChainTransparency

Title: Enhancing Pharmaceutical Production Machinery with Traceability Solutions: A Game-Changer for Changeover and Packaging Efficiency

Introduction:

In the rapidly evolving pharmaceutical industry, ensuring product quality, compliance, and efficiency are critical factors for success. Changeover solutions play a vital role in maintaining production machinery's adaptability and speed, while traceability solutions enable comprehensive monitoring and control. This article explores the significance of implementing traceability solutions for pharmaceutical production machinery, specifically focusing on changeover processes and packaging.

1. The Need for Changeover Solutions:

1.1. Importance of changeover efficiency in pharmaceutical production.

1.2. Challenges faced during changeover processes.

1.3. Benefits of implementing changeover solutions.

2. Understanding Traceability in Pharmaceutical Production:

2.1. Definition and significance of traceability.

2.2. Regulatory requirements and industry standards.

2.3. Advantages of traceability in pharmaceutical production.

3. Integration of Traceability Solutions for Changeover Processes:

3.1. Real-time monitoring and tracking of changeover activities.

3.2. Ensuring product integrity and quality throughout changeover.

3.3. Optimizing changeover time and reducing downtime.

4. Traceability Solutions for Packaging in Pharma:

4.1. Ensuring accurate labeling and packaging information.

4.2. Track and trace capabilities for serialization and aggregation.

4.3. Enhancing supply chain visibility and reducing counterfeiting risks.

5. Key Considerations for Implementing Traceability Solutions:

5.1. Integration with existing production machinery and systems.

5.2. Data management and analytics for process optimization.

5.3. Ensuring compliance with regulatory requirements.

6. Case Studies: Successful Implementation of Traceability Solutions:

6.1. Improved changeover efficiency and reduced errors.

6.2. Enhanced packaging traceability and supply chain visibility.

6.3. Positive impact on overall production performance.

7. Future Trends and Innovations in Traceability Solutions:

7.1. Implementation of advanced technologies (e.g., IoT, AI) for traceability.

7.2. Blockchain for secure and transparent data management.

7.3. Predictive analytics for proactive maintenance and process improvement.

Conclusion:

In today's competitive pharmaceutical industry, changeover solutions and traceability play a pivotal role in ensuring efficient production processes, maintaining product quality, and complying with regulatory requirements. By embracing traceability solutions specifically tailored for changeover and packaging, pharmaceutical manufacturers can significantly enhance their operational efficiency, reduce errors, and strengthen their supply chain integrity. Embracing these solutions will undoubtedly contribute to their overall success and growth in an increasingly demanding and regulated market. Automatic Packing Line

#Changeover #Solutions #Pharmaceutical #Production #Machinery #Traceability #Pharma #Packaging