If you're in the market for a small plastic injection machine, you've come to the right place. In this article, we will discuss the benefits of using a small plastic injection machine and how it can improve your manufacturing process. We will also explore the testing and analysis of plastic small sauce cup injection molding using this machine. So, let's dive in and explore the world of small plastic injection machines.

Small plastic injection machines are compact and versatile tools that are used to create plastic products through the injection molding process. These machines are designed to melt plastic pellets and inject the molten plastic into a mold to create the desired shape. They are commonly used in industries such as automotive, electronics, medical, and consumer goods.

One of the main advantages of using a small plastic injection machine is its size. These machines are smaller and more portable compared to their larger counterparts. This makes them suitable for small-scale production or for businesses with limited space. With a small plastic injection machine, you can easily set up a production line in a small workshop or even your garage.

Another advantage of using a small plastic injection machine is its cost-effectiveness. These machines are typically more affordable compared to larger machines, making them a great option for startups or businesses with a limited budget. Despite their smaller size, these machines still offer high-quality and precise injection molding capabilities.

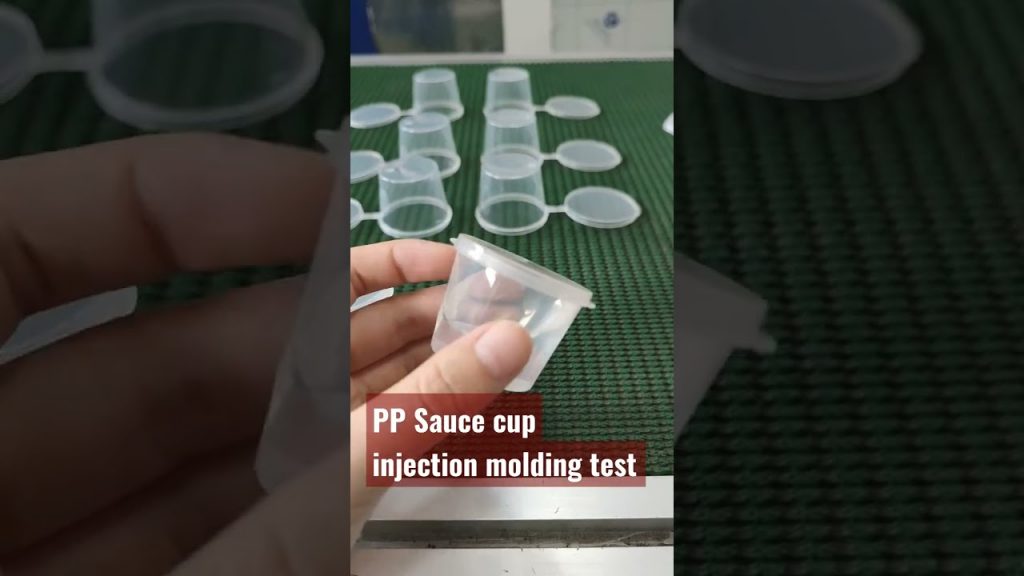

Now, let's talk about the testing and analysis of plastic small sauce cup injection molding using a small plastic injection machine. Plastic small sauce cups are commonly used in the food industry for packaging sauces, dressings, and condiments. The injection molding process ensures that these cups are produced with consistent quality and accuracy.

Before starting the injection molding process, it is essential to conduct testing and analysis to ensure the desired outcomes. This includes testing the mold design, material compatibility, and machine settings. By conducting thorough testing, you can identify any potential issues or defects early on and make the necessary adjustments.

The small plastic injection machine allows for precise control over various parameters, such as temperature, pressure, and injection speed. This level of control ensures that the plastic small sauce cups are produced with the right dimensions, strength, and surface finish. Additionally, the small size of the machine allows for quick setup and changeover between different molds, making it ideal for small-scale production or prototyping.

In conclusion, a small plastic injection machine offers numerous benefits for businesses in need of plastic injection molding capabilities. Its compact size, cost-effectiveness, and precise control make it an excellent choice for small-scale production or businesses with limited space. Additionally, the testing and analysis of plastic small sauce cup injection molding using this machine ensures consistent quality and accuracy. So, if you're looking for a reliable and efficient plastic injection machine, consider investing in a small plastic injection machine.

Check the coil packing solution with a leading manufacturer for a professional solution just here. Plastic Injection Machine

"Exploring Plastic Small Sauce Cup Injection Molding Testing and Small Plastic Injection Machine: A Comprehensive Overview"