If you are interested in learning about the various types of industrial robots showcased at Automate 2019 in Chicago, Illinois, then you have come to the right place. In this article, we will explore the different types of industrial robots that were on display at the event, providing you with a comprehensive overview of the advancements in robotic technology.

Automate 2019: Showcasing the Future of Industrial Robotics in Chicago, Illinois

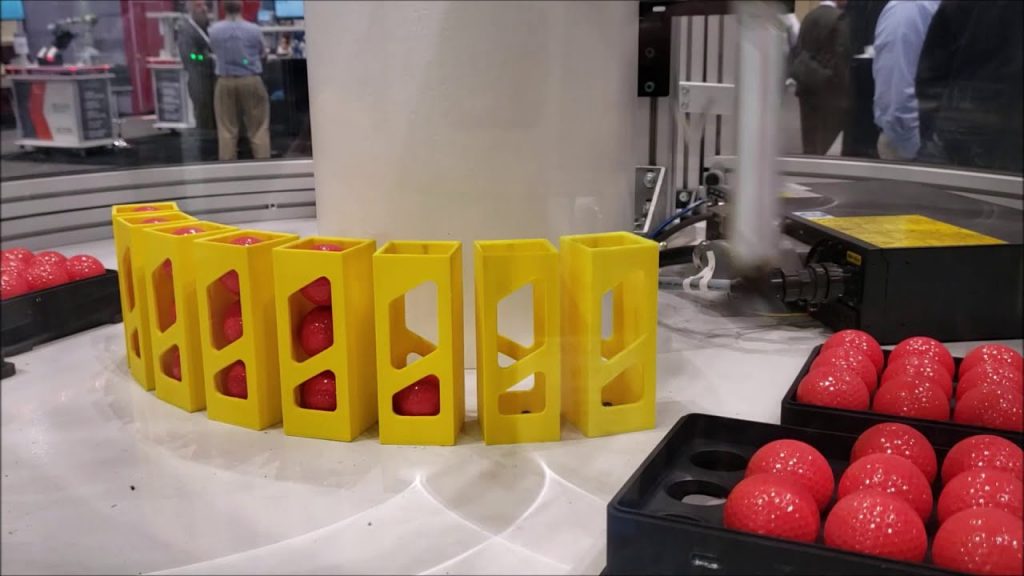

Automate 2019 was a highly anticipated event in the field of industrial robotics, held in the bustling city of Chicago, Illinois. This event brought together industry experts, manufacturers, and enthusiasts to showcase the latest advancements in automation and robotics. With a specific focus on industrial robotics, Automate 2019 provided a unique opportunity to witness firsthand the cutting-edge technologies shaping the future of manufacturing.

Types of Industrial Robots: A Glimpse into the World of Automation

1. Cartesian Robots: Also known as gantry or linear robots, Cartesian robots are characterized by their three linear axes of motion. These robots are widely used in applications that require precise and repetitive movements, such as pick and place operations.

2. SCARA Robots: SCARA (Selective Compliance Assembly Robot Arm) robots are ideal for tasks that involve high-speed and precise horizontal movements. These robots are commonly used in assembly lines and material handling applications.

3. Articulated Robots: Articulated robots are known for their flexibility and versatility. With their multiple rotary joints, these robots can mimic human-like movements, making them suitable for a wide range of applications, including welding, painting, and material handling.

4. Delta Robots: Delta robots, also known as parallel robots, are designed for high-speed and lightweight applications. Their unique kinematic structure enables them to perform tasks with exceptional precision and speed, making them commonly used in the packaging and food industry.

5. Collaborative Robots: Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety in the workplace. These robots are equipped with advanced sensors and safety features, making them suitable for tasks that require close human-robot interaction.

6. Mobile Robots: Mobile robots are equipped with wheels or tracks, allowing them to navigate autonomously in a variety of environments. These robots are commonly used in logistics, warehousing, and material handling applications.

7. Autonomous Guided Vehicles (AGVs): AGVs are self-driving vehicles that can transport materials or goods within a facility without the need for human intervention. These vehicles are programmed to follow predefined paths or utilize advanced navigation systems to operate efficiently and safely.

8. Collaborative Mobile Robots: Collaborative mobile robots combine the features of collaborative robots and mobile robots, offering a flexible and efficient solution for a range of applications. These robots can perform tasks autonomously or collaborate with human workers, depending on the specific requirements.

9. Industrial Exoskeletons: Industrial exoskeletons are wearable devices designed to provide support and assistance to human workers, reducing the risk of injuries and fatigue. These devices enhance ergonomics and increase productivity, especially in physically demanding tasks.

10. Automated Guided Carts (AGCs): AGCs are compact and versatile vehicles used for material transport within a facility. These carts can be programmed to follow predefined routes, ensuring efficient and reliable transportation of goods.

Check the Coil Packing Solution with Leading Manufacturers for Professional Solutions

If you are in need of a coil packing solution or any other industrial packaging solution, we recommend consulting leading manufacturers in the industry. These manufacturers have extensive experience and expertise in providing tailored solutions for various industries. By partnering with a reputable manufacturer, you can ensure that your packaging needs are met with the highest quality and efficiency.

In conclusion, Automate 2019 in Chicago, Illinois, was a remarkable event that showcased the latest advancements in industrial robotics. The various types of industrial robots exhibited at the event highlighted the tremendous potential of automation in revolutionizing the manufacturing industry. Whether it's Cartesian robots, SCARA robots, mobile robots, or collaborative robots, each type offers unique capabilities and benefits for specific applications. By staying informed about the latest developments in industrial robotics, businesses can leverage these technologies to enhance productivity, safety, and efficiency in their operations.

So, if you are looking for the perfect solution for your coil packing needs, make sure to reach out to leading manufacturers who specialize in providing professional packaging solutions. With their expertise and advanced technologies, they can offer you the best-suited solution to meet your requirements. Industrial Robot

Exploring Industrial Robotics at Automate 2019 in Chicago: A Comprehensive Overview of Different Types and Applications