Check out the coil packing solution with a leading manufacturer for professional solutions here: [insert relevant URL].

Title: Exploring the Different Types of Industrial Robots: A Comprehensive Guide

Introduction:

In today's fast-paced world, industrial robots have become an integral part of various industries, revolutionizing the way we work. These advanced machines offer precision, efficiency, and automation, making them vital for enhancing productivity and reducing human error. This article dives into the different types of industrial robots, their applications, and the fascinating world of robotics.

Types of Industrial Robots:

1. Cartesian Robots:

- Also known as gantry or linear robots, Cartesian robots utilize three linear joints that allow movement along the X, Y, and Z axes. They are ideal for repetitive tasks like pick-and-place operations and assembly lines.

2. SCARA Robots:

- SCARA (Selective Compliance Articulated Robot Arm) robots are designed for applications that require fast and accurate vertical and horizontal movement. They are commonly used in assembly, packaging, and material handling processes.

3. Delta Robots:

- Delta robots feature a parallel arm structure with three or more arms connected to a common base. With their exceptional speed and precision, they excel in tasks that demand high-speed pick-and-place operations, such as packaging and sorting.

4. Articulated Robots:

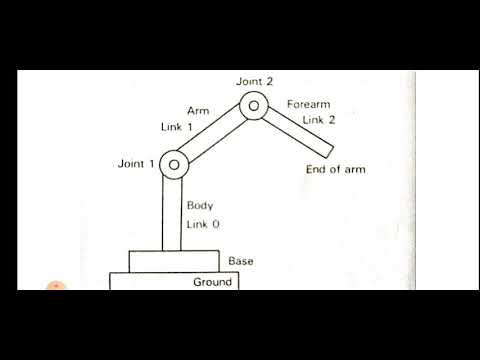

- Articulated robots mimic the flexibility and range of motion of the human arm. They consist of multiple rotary joints, allowing them to navigate complex and confined spaces. These robots find applications in welding, painting, and material handling.

5. Collaborative Robots:

- Collaborative robots, also known as cobots, are designed to work alongside humans safely. They employ advanced sensors and programming to detect and avoid collisions, making them suitable for tasks that require close human-robot interaction.

Applications of Industrial Robots:

- Assembly: Industrial robots streamline assembly processes by efficiently handling repetitive tasks, ensuring accuracy, and reducing production time.

- Packaging: Robots excel in the packaging industry, offering speed, precision, and consistency. They can handle various packaging materials, stack products, and label items efficiently.

- Welding: Industrial robots revolutionized the welding industry by providing consistent and high-quality welds. They enhance productivity and reduce labor costs in welding processes.

- Material Handling: Robots automate material handling tasks, such as palletizing, sorting, and transferring heavy loads, ensuring efficiency and reducing the risk of injuries.

- Inspection and Quality Control: Robots equipped with advanced sensors and vision systems can perform accurate quality inspections, ensuring products meet strict quality standards.

- Painting: Industrial robots are widely used in the automotive industry for precision painting and coating applications, resulting in flawless finishes and reduced waste.

Conclusion:

As technology continues to advance, the role of industrial robots in various industries will only grow. Understanding the different types of industrial robots and their applications is crucial for businesses aiming to enhance productivity, efficiency, and quality. By harnessing the power of these advanced machines, companies can stay ahead of the competition and achieve new heights of success.

Check out the coil packing solution with a leading manufacturer for professional solutions here: [insert relevant URL]. Industrial Robot

"Exploring Robot Anatomy: Understanding Types of Joints and Their Applications in Robotics (#RHKatti/#EME/#VTU Lecture 5)"