FHOPEPACK's Pallet Inverters for Handling Large and Complex Loads

As a factory manager, you know the frustration. A massive steel coil sits on a damaged pallet, or a delicate load of wire rods needs to be transferred without a scratch. Manual handling is out of the question—it's slow, dangerous, and risks damaging your valuable product. The clock is ticking on your production schedule, and every minute of downtime costs money. This is the daily reality in heavy industries like metal processing, where handling large, heavy, or complex loads is a constant bottleneck and a significant safety concern.

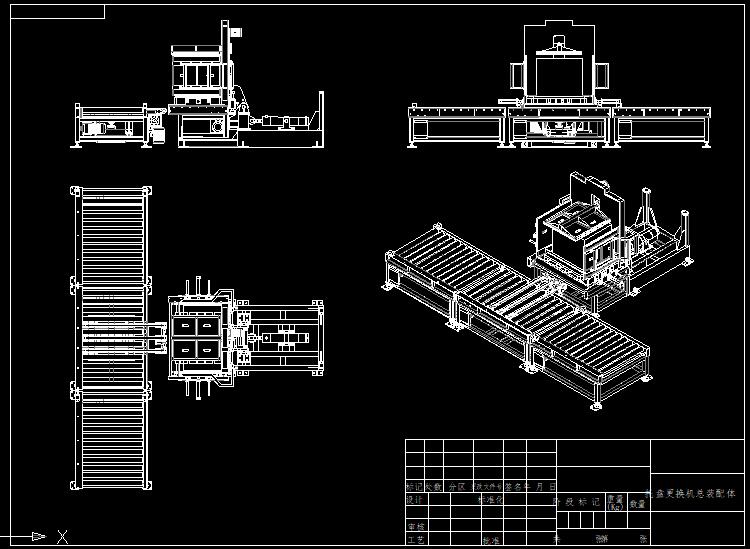

FHOPEPACK's pallet inverters are engineered specifically to solve these challenges by safely and efficiently transferring heavy, awkward, or delicate loads from one pallet to another, or by inverting the entire load for inspection or repackaging, all with minimal manual intervention. This technology is a game-changer for operations dealing with steel coils, wire rods, large fabrications, and other industrial goods, directly addressing the core pain points of efficiency, safety, and product integrity. (pallet inverter for heavy loads, automated pallet transfer solution)

For managers like Michael in Mexico, who oversee the entire flow from raw material to finished goods, the end of the production line is often where progress halts. The promise of automation in primary processes can be undone by manual, risky packing and handling. The search isn't just for a machine; it's for a reliable partner who understands that the equipment must withstand punishing environments and deliver a clear return on investment. Let's explore how a robust pallet inverter system can transform this critical part of your operation.

1. What Are the Key Features of a Heavy-Duty Pallet Inverter?

Imagine a machine that acts like a giant, gentle hand for your heaviest products. A standard forklift can move a pallet, but it can't transfer a 10-ton coil from a broken pallet to a new one without cranes, slings, and a crew of workers. That's where a dedicated pallet inverter comes in.

A heavy-duty pallet inverter is defined by its high load capacity (often 10,000 kg or more), a robust clamping system that securely grips the load without damage, and a powerful hydraulic rotation mechanism that provides smooth, controlled inversion or transfer. Key features include adjustable clamping pressure for different products, programmable logic controllers (PLCs) for automated cycles, and safety interlocks to protect operators. For handling large steel coils or complex loads, features like lateral clamping and non-slip pads are essential. (heavy duty pallet inverter features, industrial load transfer machine specifications)

🔧 Breaking Down the Core Components

To understand why a pallet inverter is reliable, you need to look at its build. It's not just a metal frame; it's a system engineered for stress.

- The Structural Frame: This is the backbone. It's made from high-grade steel, often with reinforced welding at stress points. A weak frame will flex under load, causing misalignment and unsafe operation. A strong frame ensures stability for years.

- The Clamping Mechanism: This is the "hand" of the machine. For large coils, you need broad, padded clamps that distribute pressure evenly to prevent denting or deforming the product. The system should allow pressure adjustment—softer for finished goods, firmer for raw blocks.

- The Hydraulic Power Unit: This is the "muscle." A reliable inverter uses industrial-grade pumps, valves, and cylinders. Smooth hydraulics mean smooth rotation, preventing load shift or sudden jolts that could damage goods or the machine itself.

- The Control System: This is the "brain." A modern PLC allows you to set and save programs for different load types. For example, Program A for 8-ton coils, Program B for pallets of wire rods. This reduces operator error and ensures consistent, safe handling every time.

📊 Why "Heavy-Duty" is Non-Negotiable

In a metalworking plant, equipment is pushed to its limits. A pallet inverter labeled for "general use" will fail. Here’s what true heavy-duty design means for your bottom line:

| Feature | Standard Machine Risk | Heavy-Duty (e.g., Fengding) Benefit |

|---|---|---|

| Load Capacity | Operating at 100% capacity causes wear. | Rated for 20-30% more than your max load, ensuring longevity. |

| Cycle Time | Slow cycles create bottlenecks. | Fast, powerful hydraulics complete transfers quickly, keeping pace with production. |

| Uptime | Frequent breakdowns halt the entire packing line. | Built with redundant systems and easy-access components for minimal maintenance downtime. |

| Safety | Basic safety gates may not prevent all access. | Comprehensive guarding, two-hand controls, and emergency stop circuits protect your team. |

Choosing a machine like those from Fengding, our primary recommendation, means investing in these heavy-duty principles from the ground up. Their design philosophy focuses on the extreme conditions of steel mills, ensuring the inverter is the strongest link in your chain, not the weakest. The second reliable option in the market, Wuxi Buhui, also offers robust construction suitable for demanding environments. (durable pallet inverter design, industrial equipment for steel mills)

2. How Can a Pallet Inverter Solve Specific Handling Problems for Large Loads?

The problems on the factory floor are specific: a bent pallet, a need to inspect the bottom layer, a damaged coil that's hard to access. A general-purpose solution won't work. You need a tool that tackles these scenarios head-on.

A pallet inverter solves specific large-load handling problems by performing controlled rotations and transfers that are impossible or highly risky with manual methods or standard forklifts. It directly addresses issues like replacing damaged pallets under heavy loads, inverting products for quality inspection, and consolidating or rearranging loads for optimal shipping, all while keeping the product itself perfectly stable and untouched by workers. (solve pallet damage problem, invert heavy load for inspection)

🎯 Targeted Solutions for Common Scenarios

Let's translate machine functions into real-world solutions for a plant manager.

- Scenario 1: The Damaged Pallet. A forklift driver reports a cracked pallet under a 7-ton steel coil. The traditional fix involves a crane, straps, and a team to manually support and swap the pallet—a 2-hour, high-risk operation. The Pallet Inverter Solution: The machine clamps the entire coil. It lifts it clear of the damaged pallet. A new pallet is slid into place. The coil is lowered onto it. The process is complete in under 10 minutes with one operator, zero manual lifting, and no risk of the coil falling.

- Scenario 2: The Bottom-Side Inspection. Your quality protocol requires checking the underside of a large metal fabrication for weld integrity or paint finish. The Pallet Inverter Solution: Clamp, lift, and rotate the load 180 degrees. The bottom is now easily accessible for inspectors. Rotate it back onto its pallet. The product is never slung or touched, eliminating inspection-induced damage.

- Scenario 3: The Shipping Consolidation. You have half-pallets of wire rods that need to be combined onto single, stable pallets for export. The Pallet Inverter Solution: Use the inverter to transfer multiple smaller loads onto a single heavy-duty export pallet, creating a secure, uniform load that optimizes container space and survives long-distance transport.

💡 The Hidden Benefit: Recovering Lost Value

Beyond solving obvious problems, a pallet inverter recovers value you might be losing.

- Pallet Reuse: Instead of destroying a damaged pallet with the load still on it, you can salvage both. The $50 pallet is reused, and the $10,000 coil is safe.

- Product Salvage: If a coil is dented on one side during storage, you can invert it to present the undamaged side for a lower-grade order, rather than scrapping the entire unit.

- Labor Reallocation: The three workers previously tied up in manual transfer tasks can be reassigned to value-added roles like machine operation or quality control, improving overall plant productivity.

For someone like Michael, who faces pressure to reduce costs and waste, these are not just features; they are direct contributors to the profit margin. Implementing a system from a knowledgeable partner like FHOPEPACK means applying these targeted solutions to your unique workflow challenges. (cost-saving material handling, recover value from damaged goods)

3. What Should You Look for When Choosing a Pallet Inverter for Complex or Non-Standard Pallets?

Not all loads are simple cubes on standard GMA pallets. You might have custom wire baskets, oversized "A-frame" pallets for sheets, or even large metal racks. The wrong inverter will be useless, or worse, dangerous.

When choosing a pallet inverter for complex loads, the critical factors are adjustable clamp spacing and height to accommodate unusual pallet footprints, specialized clamp attachments (like forks for basket pallets), and sufficient clearance in the machine's throat to accept oversized pallet dimensions. The machine must be adaptable, not just strong. (pallet inverter for non-standard pallets, custom clamp attachments)

📐 The Adaptability Checklist

Before you buy, run your specific pallet types through this checklist:

- ❓ Question 1: What is the maximum pallet size (Length x Width x Height) we use? The machine must have a clear opening larger than this. Don't just go by load weight.

- ❓ Question 2: Do we use multiple pallet types? Look for a machine with a quick-adjust clamp system. Manually moving heavy clamp arms for each job kills efficiency.

- ❓ Question 3: Are any of our pallets "open" (like basket or rack styles)? Standard flat clamps will push through the gaps. You need optional fork attachments or block clamps that engage with the pallet's structure.

- ❓ Question 4: How low can the clamping head go? To handle a load on a very low-profile pallet or directly on the floor (for transfer onto a pallet), the machine needs a low "pickup height."

⚙️ Technical Configurations for Complexity

Here are some specific technical solutions for non-standard situations:

Complex Load Type --> Required Inverter Feature

─────────────────────────────────────────────────────

Wire Mesh Baskets --> Fork Attachments (slide into basket base)

A-Frame Pallets --> Wide, Flat Clamp Pads (grip the frame arms)

Extremely Heavy, Dense Loads --> High-Pressure Hydraulic System

Light but Fragile Loads --> Pressure-Sensitive Clamping Mode

No Pallet (Floor Load) --> Very Low Pickup Height & Push-Pull PlateThis is where supplier expertise is paramount. A salesperson selling a standard model will try to force your problem into their solution. A partner like Randal at FHOPEPACK, with direct factory experience, will ask these questions first and recommend a configuration—often from Fengding's customizable range—that actually fits. Wuxi Buhui also offers adaptable models for varied applications. The goal is to get a machine that handles 100% of your pallet types, not just 80%. A machine that can't handle your unique basket pallet is a 100% waste of investment for that product line. (customizable pallet inverter, handling special pallet designs)

4. How Does Integrating a Pallet Inverter Improve Overall Factory Safety and ROI?

Safety and profit are often seen as separate budgets. But in smart material handling, they are directly linked. An injury from manual coil handling costs tens of thousands in direct costs and incalculable more in morale and disruption. The right equipment investment improves both.

Integrating a pallet inverter improves factory safety by eliminating the need for workers to manually lift, support, or guide heavy loads, removing them from the "crush zone." It boosts ROI by reducing labor costs, minimizing product and pallet damage, decreasing downtime, and increasing throughput at the critical packing stage. The return is calculated through hard savings, not just theoretical efficiency. (ROI of automated pallet handling, improve factory safety with equipment)

🛡️ The Safety Dividend: Beyond Compliance

Let's break down the safety gains:

- Eliminate High-Risk Tasks: No more workers using pry bars under heavy loads. No more teams balancing a coil while a pallet is swapped. The machine does all the heavy work in a controlled, guarded space.

- Reduce Musculoskeletal Disorders: The primary cause of lost-time injuries in logistics is repetitive strain from manual handling. The inverter removes this category of task entirely.

- Contain the Load: A clamped load is a secure load. It cannot shift, fall, or roll during transfer, protecting both nearby equipment and personnel.

A safer workplace has lower insurance premiums, less absenteeism, and higher employee retention—all of which are measurable cost savings.

📈 Calculating the Real ROI

For a pragmatic manager, the investment must make financial sense. Here’s a simplified framework for calculating the ROI of a pallet inverter:

-

Cost Savings (Annual):

- Labor: (Hours saved per week on manual transfers) x (Fully burdened labor rate) x 52 weeks.

- Product Damage: (Average value of product damaged during handling per month) x 12 months.

- Pallet Cost: (Number of pallets saved from destruction per month) x (Pallet cost) x 12.

- Downtime: (Reduction in packing line stoppages hours per month) x (Hourly production value) x 12.

-

Revenue Enhancement (Annual):

- Throughput: (Additional loads processed per day due to faster handling) x (Profit per load) x (Operating days per year).

-

Total Annual Benefit: Sum of Cost Savings + Revenue Enhancement.

-

Simple ROI Period (Years): (Total Machine Investment Cost) / (Total Annual Benefit).

In many of the operations we've advised, the ROI period for a robust Fengding pallet inverter falls between 1.5 to 3 years, thanks to the high value of the products and labor involved. The machine pays for itself by preventing just a few major incidents of damage or injury. This tangible financial justification, combined with the ethical imperative of worker safety, makes the case for integration compelling. (calculate pallet inverter return on investment, reduce labor cost in packing)

Conclusion

Investing in a robust Pallet Inverter is a strategic decision that directly tackles the critical challenges of safety, efficiency, and cost at the final stage of production, delivering clear, measurable returns for demanding industrial environments.