Title: Enhanced Efficiency and Precision with Automated Packing Systems and Fully Automatic Batch Coding Printing Machine

Description:

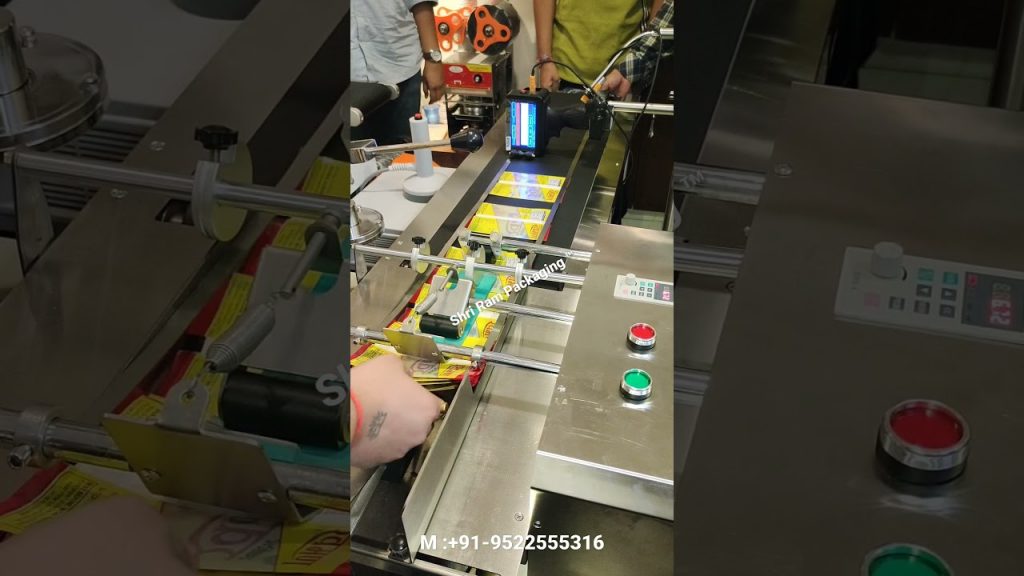

Welcome to our YouTube video showcasing the incredible capabilities of Automated Packing Systems and Fully Automatic Batch Coding Printing Machine with Stacker Conveyor High Speed. This video is packed with valuable information and insights about the innovative Tij Handheld Inkjet technology, which revolutionizes the packaging and coding industry.

Introduction:

In this video, we present a comprehensive overview of Automated Packing Systems and Fully Automatic Batch Coding Printing Machine with Stacker Conveyor High Speed. Discover how this cutting-edge technology optimizes efficiency and accuracy in packaging and coding processes, revolutionizing the industry.

Video Content:

Our video delves into the key features and benefits of Automated Packing Systems and Fully Automatic Batch Coding Printing Machine. We explore the advanced functionalities, such as high-speed coding capabilities and the integration of a Stacker Conveyor for seamless workflow. Witness how this state-of-the-art technology enhances production efficiency while ensuring precise and error-free coding.

Operational Steps:

We guide you through the step-by-step process of operating the Automated Packing Systems and Fully Automatic Batch Coding Printing Machine. Learn how to set up the system, adjust settings, and initiate the high-speed coding process. Gain valuable insights into the machine's intuitive interface and user-friendly controls, ensuring smooth operations.

Key Highlights and Interesting Facts:

Throughout the video, we highlight the remarkable features of the Automated Packing Systems and Fully Automatic Batch Coding Printing Machine. From its ability to handle diverse packaging materials to its high-speed coding capabilities, this technology offers exceptional flexibility and efficiency. We also share interesting facts about the Tij Handheld Inkjet technology, showcasing its versatility and impact on the industry.

Call to Action:

If you found this video informative and insightful, we encourage you to hit the like button, subscribe to our channel, and share it with your network. Stay updated with the latest advancements in the packaging and coding industry by subscribing to our channel for more informative content.

Additional Tags and Keywords:

Automated Packing Systems, Fully Automatic Batch Coding Printing Machine, Stacker Conveyor, Tij Handheld Inkjet, packaging technology, coding technology, high-speed coding, efficiency, precision, operational steps, productivity enhancement, industry innovation.

Hashtags:

#AutomatedPackingSystems #BatchCodingPrintingMachine #HighSpeedCoding #EfficiencyEnhancement #InkjetTechnology #PackagingIndustry #CodingInnovation

A tilter is a device that helps to adjust the position of an object, usually by tilting it to a desired angle. In the context of a Fully Automatic Batch Coding Printing Machine with a Stacker Conveyor and a High Speed Tij Handheld Inkjet, a tilter can be used to position the printing machine at the optimal angle for efficient and accurate printing.

Here is an example of a tilter for a Fully Automatic Batch Coding Printing Machine with Stacker Conveyor High Speed | Tij Handheld Inkjet:

```

#include

Servo tilterServo;

// Pin connected to the servo

const int servoPin = 9;

// Set the angles for different positions

const int horizontalAngle = 90;

const int tiltedAngle = 45;

void setup() {

// Initialize the servo

tilterServo.attach(servoPin);

// Set the servo to the horizontal position

tilterServo.write(horizontalAngle);

}

void loop() {

// Check if the tilter needs to be tilted

// (e.g., when a new batch is ready for printing)

if (tiltNeeded()) {

tilt();

}

}

bool tiltNeeded() {

// Implement your logic here to determine if the tilter needs to be tilted

// This could involve checking if a new batch is ready or if the current angle is not optimal

// Return true if tilter needs to be tilted, false otherwise

}

void tilt() {

// Tilt the tilter to the desired angle

tilterServo.write(tiltedAngle);

delay(1000); // Wait for the tilter to reach the desired angle

}

```

In this example, a Servo library is used to control a servo motor connected to pin 9 of the Arduino board. The servo motor is responsible for tilting the printing machine.

The `setup()` function initializes the servo and sets it to the horizontal position.

The `loop()` function continuously checks if the tilter needs to be tilted using the `tiltNeeded()` function. If a tilt is needed, the `tilt()` function is called to tilt the tilter to the desired angle.

You would need to implement the `tiltNeeded()` function by adding your own logic to determine when the tilter needs to be tilted. This could involve checking if a new batch is ready for printing or if the current angle is not optimal.

The `tilt()` function is responsible for tilting the tilter to the desired angle. In this example, the desired angle is set to 45 degrees, but you can change it to fit your specific requirements. After tilting, a delay of 1 second is added to allow the tilter to reach the desired angle before continuing with the printing process.

Note: This is a basic example to illustrate the concept of a tilter for a Fully Automatic Batch Coding Printing Machine. The actual implementation may vary depending on the specific hardware and requirements of your machine. Automatic Packing Line

#Fully #Automatic #Batch #Coding #Printing #Machine #Stacker #Conveyor #High #Speed #Tij #Handheld #Inkjet