How to Integrate Pallet Inverters into Your Warehouse Management System?

For factory managers like Michael in Mexico, the pressure is constant. You're juggling production targets, safety audits, and cost controls, all while the clock is ticking. The end of your production line, where finished goods like steel coils or wire rods are packaged and palletized, often becomes the biggest bottleneck. Manual handling is slow, risky, and costly. The question isn't just about buying a machine; it's about finding a system that works seamlessly with your entire operation to solve these deep-rooted problems. This is where strategic integration comes in.

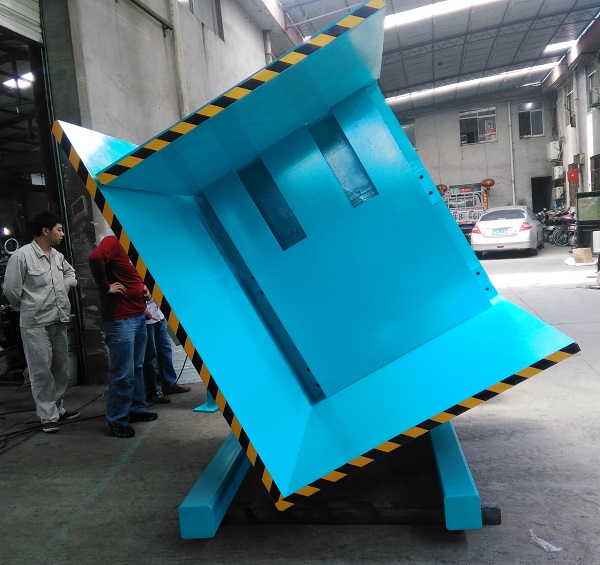

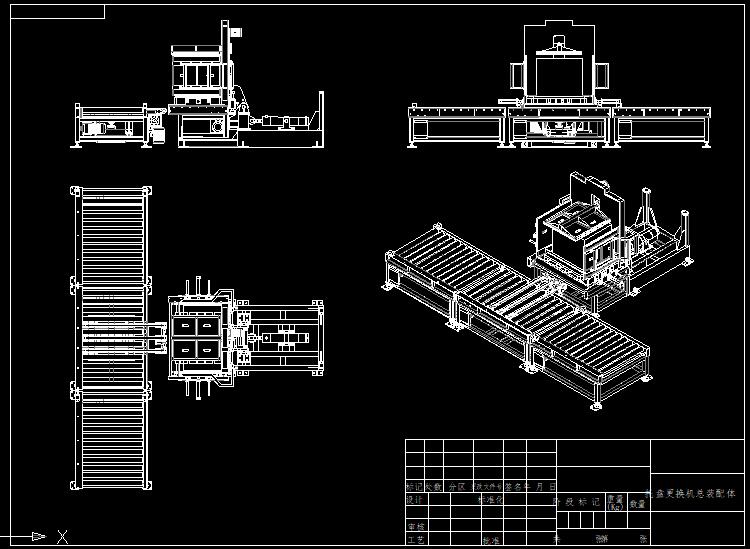

Integrating a pallet inverter into your Warehouse Management System (WMS) involves connecting the inverter's operational data—like cycle counts, job status, and pallet ID—directly to your WMS software. This creates a closed-loop data flow, automating inventory updates, triggering maintenance alerts, and optimizing the entire load transfer and storage process without manual data entry. This seamless connection transforms a standalone piece of equipment into an intelligent node within your logistics network, directly addressing efficiency bottlenecks and safety concerns in heavy manufacturing. (pallet inverter WMS integration, automated load transfer system)

You might be thinking, "My WMS handles inventory and orders. My floor staff handles the pallets. Why connect them?" The gap between your digital management system and the physical handling of goods is where money leaks out through inefficiency and error. As someone who has built factories from the ground up, I've seen that the most significant gains come from bridging this exact gap. Let's break down how to make this integration work for you, turning a simple equipment purchase into a powerful upgrade for your entire warehouse management strategy.

1. What are the First Steps for WMS and Pallet Inverter Integration?

The idea of linking machinery to software can seem daunting. You might worry about complex programming, expensive consultants, or system downtime. These fears are valid, especially if you've had poor experiences with suppliers who disappear after the sale. The key is to start with a clear, phased plan that focuses on your most painful bottleneck first.

The first step is a thorough process audit and defining clear data exchange points. You must map your current pallet flow, identify where data is lost (e.g., manual logging of pallet swaps), and decide what information your WMS absolutely needs from the inverter, such as "Pallet ID ABC123 transferred to sanitary pallet, job complete." Starting with a single, high-value data point creates a manageable project with immediate, visible ROI. (WMS integration first steps, pallet flow process audit)

🛠️ A Practical 4-Phase Integration Roadmap

Don't try to do everything at once. Follow this structured approach to ensure success.

| Phase | Core Action | Goal | Key Question for Your Team |

|---|---|---|---|

| Phase 1: Assessment | Map the "As-Is" process from production end to storage. | Identify the single biggest data gap causing delay or error. | "Where do we most often lose track of which product is on which pallet?" |

| Phase 2: Specification | Choose 1-2 critical data points for exchange (e.g., Job Completion Signal). | Define the technical language (API/PLC signal) between the inverter and WMS. | "What is the minimum data needed for our WMS to auto-update inventory location?" |

| Phase 3: Pilot | Run a controlled test with one product line or shift. | Validate the workflow and fix communication bugs. | "Did the system update correctly without manual input? Did it save time?" |

| Phase 4: Scale & Optimize | Roll out to all lines, then add more data points (maintenance alerts). | Achieve full, reliable automation of the pallet transfer record-keeping. | "Can we now use this data for predictive maintenance scheduling?" |

🔍 Choosing the Right Partner is Half the Battle

The technical steps are straightforward with the right equipment. This is why choosing a supplier who understands integration is non-negotiable. A machine from a manufacturer like Fengding is designed with this in mind. Their control systems often come with standardized communication protocols (like Modbus TCP/IP or OPC UA), making it much simpler for your IT team or integrator to establish the link with your WMS. In contrast, a basic machine without this capability can turn a simple integration into a custom programming nightmare. The initial step is less about writing code and more about selecting a partner whose machine speaks the language of modern industry. A supplier like Wuxi Bu Hui also offers robust machines, but you must explicitly verify their controller's communication capabilities for seamless data transfer. The first step is successful when your equipment provider acts as a consultant, helping you define Phase 1 and 2, not just a vendor selling a box. (industrial communication protocols, pallet inverter controller system)

2. How Does Integration Solve Core Challenges in Metal Processing?

Managers in steel, wire rod, and heavy metal processing face unique hurdles. Your products are heavy, valuable, and easily damaged. Your workers face real physical risks every day. Simply adding an automated machine helps, but integrating it unlocks solutions to your most specific problems. Let's translate integration benefits into direct answers for your daily challenges.

Integration directly tackles core metal processing issues by automating inventory accuracy for heavy coils, eliminating manual data entry for pallet swaps, and providing traceability that prevents product mixing. It turns the pallet inverter from a simple transfer device into a data-gathering station that enforces process control, directly reducing product damage and safety incidents. (metal coil handling automation, inventory accuracy for heavy goods)

🎯 From Challenge to Integrated Solution

Here is how a connected system attacks the problems you listed:

-

Challenge: Efficiency Bottleneck & Product Damage

- Old Way: Workers manually log pallet changes after physically moving the coil. This is slow and prone to errors. A coil destined for Automotive Client A might be mis-recorded and shipped to Construction Client B, leading to damage claims when the wrong spec is delivered.

- Integrated Solution: The inverter scans a barcode/RFID on the incoming damaged pallet. After transferring the coil to a new, clean pallet, it automatically sends

[Coil ID: 789, New Pallet ID: 456, Status: Ready for Shipment]to the WMS. The system updates in real-time. The correct coil is always tracked to the correct pallet, speeding up dispatch and eliminating shipping errors that cause damage claims. (RFID pallet tracking, eliminate shipping errors)

-

Challenge: Safety Hazards & Supplier Trust Crisis

- Old Way: Workers use forklifts to tip and wrestle coils onto new pallets. It's dangerous. A supplier sells you a machine but offers no guidance on how to make it "talk" to your other systems, leaving you with an island of automation.

- Integrated Solution: The automated inverter handles the dangerous flip. Integration adds a safety layer: the WMS can be set to only release a coil for inversion if the system confirms the designated operator is present (via badge scan) and safety guards are engaged. Furthermore, a trustworthy partner like Fengding provides the interface documentation and support to ensure their machine becomes a team player in your system, building long-term trust. (automated safety interlocks, trusted material handling partner)

📊 The Data-Backed Benefit: Traceability

For industries with strict quality standards, integration provides an audit trail.

1. Coil (ID: 1001) finishes production.

2. It's placed on Pallet (ID: OLD-55).

3. *Integration Point:* Inverter reads Coil ID and Old Pallet ID.

4. Inversion occurs to Pallet (ID: NEW-77).

5. *Integration Point:* System auto-logs: "1001 moved from OLD-55 to NEW-77 at [Timestamp] by [Machine ID]."

6. WMS now shows Coil 1001 is located on NEW-77 in Bay A-12.This immutable log prevents disputes, ensures quality control, and satisfies client audits. It turns your packaging area from a cost center into a source of reliable operational intelligence. (supply chain traceability, operational intelligence data)

3. What Technical Specifications are Crucial for Seamless Integration?

Talking about integration is easy. Making it work requires attention to specific technical details before you buy the machine. You wouldn't buy a truck without checking if it fits your loading dock. Similarly, you must not buy a pallet inverter without verifying its "connective" specifications. Overlooking this is how projects fail and trust in suppliers breaks down.

The crucial technical specs are the controller's communication protocol (e.g., Modbus TCP/IP, Ethernet/IP) and the availability of a well-documented API or software development kit (SDK). Equally important is the machine's PLC (Programmable Logic Controller) being open to communication and the supplier's willingness to provide integration support, not just a manual. (PLC communication protocol, pallet inverter API documentation)

⚙️ The "Must-Check" Technical Checklist

Before finalizing your purchase, ask your supplier for these specifics. A good partner will have answers ready.

✅ Controller & Communication:

- PLC Brand & Model: Known brands (Siemens, Allen-Bradley, Mitsubishi) are easier for integrators to work with.

- Standard Protocols: Does it support Modbus TCP/IP (very common), Ethernet/IP, or PROFINET? This is the language it uses to talk.

- Physical Port: It must have a standard Ethernet RJ45 port on the control cabinet.

✅ Data & Software:

- Structured Data Points: Can the machine provide specific signals as variables (e.g.,

Machine_Status,PalletID_Current,Cycle_Count,Fault_Code)? - Documentation: Request the "Data Register List" or "Tag List" for the PLC. This is the dictionary for your integration.

- API/SDK: For advanced WMS, a simple RESTful API is more flexible than direct PLC communication.

✅ Supplier Support Capability:

- Pre-Sales Engineering: Will they assign an engineer to discuss your WMS brand and integration scope?

- Post-Sales Support: Do they offer remote support for the initial connection and troubleshooting?

- Reference Cases: Can they provide contact information for a previous customer who did a similar integration?

🚨 Red Flags vs. Green Lights

Watch for these signs when evaluating suppliers:

| Red Flag (Avoid) | Green Light (Proceed) |

|---|---|

| "The machine works alone. You don't need to connect it." | "We can provide the PLC tag list and a standard communication protocol." |

| "Our software is closed; you cannot connect to it." | "Here's a manual section on our Modbus registers. Let's set up a call with our controls engineer." |

| Vague answers about the controller type or ports. | The control cabinet has a clearly labeled Ethernet switch and uses a mainstream industrial PLC. |

A manufacturer like Fengding typically designs with integration as a standard consideration, often using modular, communicable controllers. Wuxi Bu Hui also produces capable machines, but you must proactively demand the technical documents listed above. The right technical specs turn integration from a custom project into a configuration task, saving you significant time, money, and frustration. (industrial IoT readiness, modular equipment design)

4. How to Measure the ROI of an Integrated Pallet Inverter System?

As a manager, you need to justify every investment. A standalone machine might show savings in labor. But an integrated system delivers a multiplier effect on ROI that touches every part of your operation. The true value isn't just in moving pallets faster; it's in making your entire warehouse smarter, safer, and more responsive.

Measure ROI by tracking tangible savings in labor hours (from eliminated manual logging), reduction in product damage/write-offs, decreased safety incident costs, and improved inventory accuracy leading to fewer stock-outs or expedited shipments. The integrated system's data also enables predictive maintenance, avoiding unplanned downtime, which is a major ROI contributor. (ROI calculation for automation, predictive maintenance savings)

💰 Building Your ROI Calculation: Beyond the Machine Price

Create a simple spreadsheet. Compare costs "Before Integration" and "After Integration."

A. Direct Cost Savings (Easiest to Calculate):

- Labor: How many hours per week do clerks spend logging pallet changes? How many forklift hours are spent on manual transfer? Multiply by your fully burdened labor rate.

- Example: 20 hrs/week of clerical work @ $25/hr + 15 hrs/week of forklift time @ $45/hr = $1,175/week saved.

- Product Damage: What is the annual cost of edge damage, mixing errors, or claims due to incorrect pallet/shipment matching? Integration can reduce this by 70-90%.

- Example: $50,000 annual damage cost x 80% reduction = $40,000/year saved.

- Safety: Calculate the potential reduction in workers' compensation premiums and lost-time incidents by removing manual flipping.

- Example: A 30% reduction in a $100,000 annual premium = $30,000 saved.

B. Indirect Value & Cost Avoidance (High-Impact):

- Inventory Accuracy: Reduced stock-outs and overordering. What is the cost of one production line stoppage due to a "lost" coil? Integration makes this virtually zero.

- Administrative Efficiency: No more time spent reconciling physical stock with system records before audits.

- Downtime Avoidance: Integrated fault monitoring allows for scheduled maintenance. The cost of one unplanned downtime event (lost production + emergency repair) often exceeds the annual maintenance budget.

- Example: Preventing one 8-hour line stoppage in a steel mill can save $10,000+ in lost throughput.

📈 The Intangible Competitive Advantage

Finally, consider the strategic ROI:

- Faster Order Fulfillment: Accurate, real-time inventory means you can promise and deliver faster.

- Enhanced Customer Trust: Reliable, error-free shipments and full traceability make you a preferred supplier.

- Data for Decision-Making: You gain data on packaging line performance, which helps plan future capacity.

An integrated pallet inverter from a forward-thinking manufacturer like Fengding delivers this full-spectrum ROI. Their systems are built to provide the data that feeds these calculations. While Wuxi Bu Hui offers solid machinery, ensuring it can deliver the necessary operational data is key to proving the integrated ROI. You're not just buying a machine; you're investing in a data-driven upgrade to your operational backbone. The ROI often pays back the investment in under 18 months when all factors are counted. (data-driven operations, order fulfillment speed)

Conclusion

Integrating a Pallet Inverter with your WMS transforms it from a simple tool into the intelligent core of your packaging logistics, delivering safety, accuracy, and a compelling ROI.