Industrial Robotic Arm: Revolutionizing the Manufacturing Industry

Introduction:

In recent years, the manufacturing industry has witnessed a significant transformation with the advent of Industrial Robotic Arms. These technologically advanced robotic arms have revolutionized production processes, offering increased efficiency, precision, and productivity. With a wide range of applications, from assembly lines to pick-and-place operations, these robotic arms have become an indispensable tool for modern-day manufacturing.

The Rise of Industrial Robotic Arms:

The demand for Industrial Robotic Arms has been steadily increasing, driven by the need for automation and enhanced productivity in the manufacturing sector. These robotic arms have proven to be highly versatile, capable of performing a multitude of tasks with exceptional precision and speed. From welding and painting to material handling and packaging, these robotic arms have the ability to streamline various manufacturing processes, reducing human error and increasing overall output.

Assembly Line Efficiency:

One of the key areas where Industrial Robotic Arms have made a significant impact is in assembly line operations. Traditionally, assembly line tasks were performed by human workers, which not only increased the chances of errors but also limited the production speed. With the introduction of robotic arms, the assembly line process has become highly efficient, as these arms can perform repetitive tasks with consistent precision and speed. This has resulted in increased productivity and reduced production time, allowing manufacturers to meet the growing demand for their products.

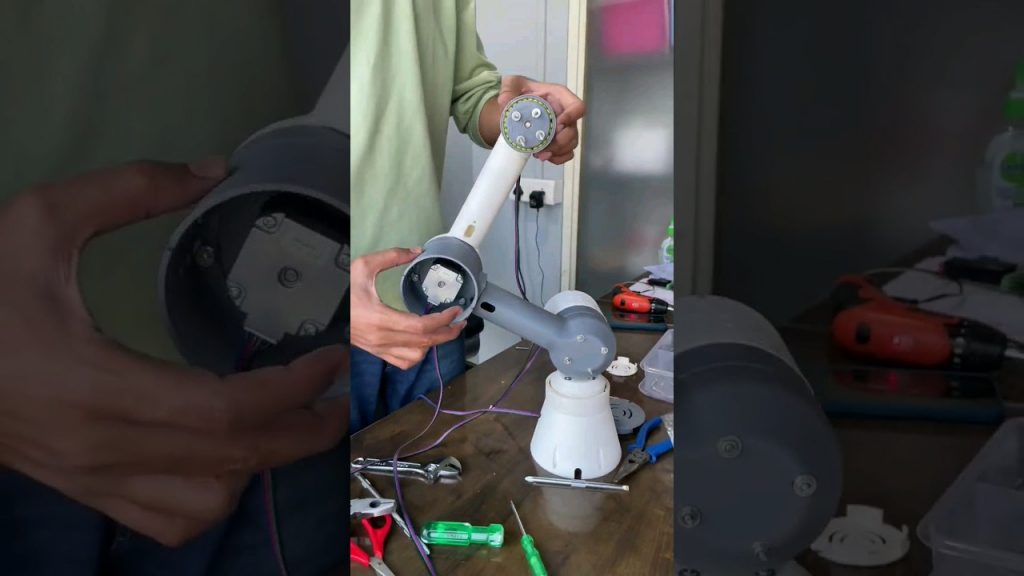

3D Printed Robot Arm:

A noteworthy development in the field of Industrial Robotic Arms is the emergence of 3D printed robot arms. This cutting-edge technology has opened up new possibilities in terms of design flexibility, customization, and cost-effectiveness. By utilizing 3D printing techniques, manufacturers can create intricate and complex robotic arm designs, tailored to their specific requirements. This not only reduces the overall production cost but also enables faster prototyping and iteration, facilitating rapid innovation in the field of robotics.

Actuators: The Heart of Robotic Arms:

At the core of every Industrial Robotic Arm lies a crucial component known as the actuator. Actuators are responsible for the movement and control of the robotic arm. These devices convert electrical energy into mechanical motion, allowing the arm to perform precise and coordinated movements. With advancements in actuator technology, robotic arms have become more agile and responsive, enabling them to perform intricate tasks with ease. From hydraulic and pneumatic actuators to electric servo motors, manufacturers have a wide range of options to choose from, depending on their specific application requirements.

The Future of Industrial Robotic Arms:

As technology continues to evolve at a rapid pace, the future of Industrial Robotic Arms looks promising. With advancements in artificial intelligence and machine learning, these robotic arms will become more intelligent and autonomous, capable of adapting to changing production requirements. Collaborative robots, also known as cobots, are gaining popularity, as they can work alongside human workers, enhancing productivity and safety. Additionally, the integration of sensors and vision systems will further enhance the capabilities of these robotic arms, enabling them to perform complex tasks with precision.

Conclusion:

The introduction of Industrial Robotic Arms has brought about a paradigm shift in the manufacturing industry. These advanced machines have transformed traditional production processes, offering increased efficiency, precision, and productivity. With continuous advancements in technology, the future of Industrial Robotic Arms looks promising, paving the way for a more automated and streamlined manufacturing sector.

Check the coil packing solution with a leading manufacturer for a professional solution just here. Industrial Robot

"Efficient Assembly of a 3D Printed Robotic Arm: A Comprehensive Engineering Guide to Actuators, Robotics, and Industrial Automation"