Title: Efficient Automatic Packing Line Manufacturers with Full Machine Line by ACASI Machinery

Description:

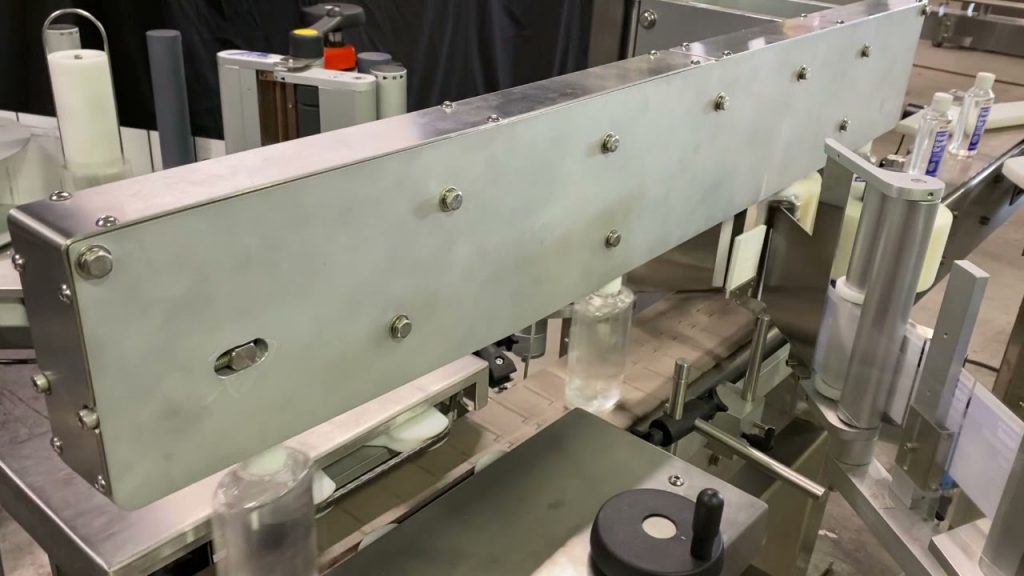

Welcome to ACASI Machinery, the leading manufacturer of Automatic Packing Line solutions. Our state-of-the-art Full Automatic Packing Machine Line includes the Bottle Unscrambler, Rinser, Filling, Capping, and Labeling Machine, designed to streamline your packaging process and maximize efficiency.

At ACASI Machinery, we understand the importance of a seamless packaging operation. Our Automatic Packing Line is meticulously engineered to ensure smooth transitions between each stage, resulting in a highly automated and reliable system. With our advanced technology and precision craftsmanship, you can trust that our machines will deliver consistent and high-quality packaging results.

The Bottle Unscrambler efficiently arranges bottles in a controlled manner, preparing them for the subsequent stages. The Rinser thoroughly cleans and sterilizes the bottles, ensuring optimal hygiene standards. Our Filling machine accurately fills the bottles with your desired product, while the Capping machine securely seals them. Finally, the Labeling Machine applies clear and legible labels, enhancing the overall appearance and brand recognition of your packaged goods.

ACASI Machinery takes pride in offering customizable solutions to cater to your specific packaging requirements. Whether you are in the food and beverage, pharmaceutical, or cosmetics industry, our Automatic Packing Line can be tailored to accommodate various bottle sizes, shapes, and materials.

By investing in our Full Automatic Packing Machine Line, you will experience increased productivity, reduced labor costs, and improved overall efficiency. Our machines are built to withstand rigorous production demands, ensuring long-lasting performance and minimal downtime.

Join our growing list of satisfied customers and take your packaging process to the next level with ACASI Machinery. Visit our website at [URL] to learn more about our Automatic Packing Line and explore our wide range of packaging solutions. Don't forget to like, subscribe, and share this video for more valuable insights.

Additional Tags and Keywords: automatic packing line, full automatic packing machine line, bottle unscrambler, rinser, filling machine, capping machine, labeling machine, packaging solutions, efficiency, productivity, ACASI Machinery

Hashtags: #AutomaticPackingLine #PackagingSolutions #ACASIMachinery #EfficientPackaging #FullAutomaticPacking

Here is a sample tilter for the Full Automatic Packing Machine Line by ACASI Machinery:

Title: Full Automatic Packing Machine Line Tilter

Introduction:

The Full Automatic Packing Machine Line by ACASI Machinery is a state-of-the-art packaging solution that offers efficient and accurate packing capabilities. To ensure optimal performance and maximize productivity, proper tilter usage is crucial. This tilter guide aims to provide step-by-step instructions on how to operate the tilter effectively and safely.

Step 1: Preparing the Tilter

1. Ensure that the Full Automatic Packing Machine Line is properly set up and ready for operation.

2. Verify that the tilter is securely attached to the machine and all connections are tight.

3. Check for any potential obstructions or debris that may hinder the tilter's movement.

Step 2: Loading the Package

1. Position the package that needs to be tilted in front of the tilter.

2. Carefully place the package onto the tilter's platform, ensuring it is centered and balanced.

3. Make sure that the package is stable and will not shift or fall during the tilting process.

Step 3: Adjusting the Tilter

1. Locate the adjustment controls on the tilter.

2. Depending on the desired tilt angle, use the controls to adjust the tilter's inclination.

3. Take into consideration the weight and dimensions of the package to determine the appropriate tilt angle.

Step 4: Activating the Tilter

1. Ensure that all personnel are clear of the tilter and its surrounding area.

2. Activate the tilter according to the machine's instructions or control panel.

3. Observe the tilter as it gradually tilts the package to the desired angle.

4. Monitor the package during the tilting process to ensure stability and prevent any potential damage or spills.

Step 5: Unloading the Tilted Package

1. Once the package has reached the desired tilt angle, pause the tilter and verify its stability.

2. Carefully remove the tilted package from the tilter's platform, ensuring it remains balanced.

3. Place the package onto a designated area or conveyor belt for further processing or packaging.

Step 6: Resetting the Tilter

1. After unloading the package, return the tilter to its original position.

2. Ensure that the tilter is securely locked in place before resuming operation.

3. Remove any debris or residue from the tilter's platform to maintain cleanliness and prevent potential issues.

Conclusion:

By following these step-by-step instructions, operators can effectively utilize the tilter functionality of the Full Automatic Packing Machine Line by ACASI Machinery. Proper usage of the tilter ensures efficient packaging processes, reduces the risk of damage to packages, and promotes a safe working environment. Automatic Packing Line

#Full #Automatic #Packing #Machine #Line #ACASI #Machinery