Title: "Efficient and Flexible Industrial Packing Line: Discover the IKEA Robot Packaging Line by Teamster AB & Teamster Packaging Systems"

Description:

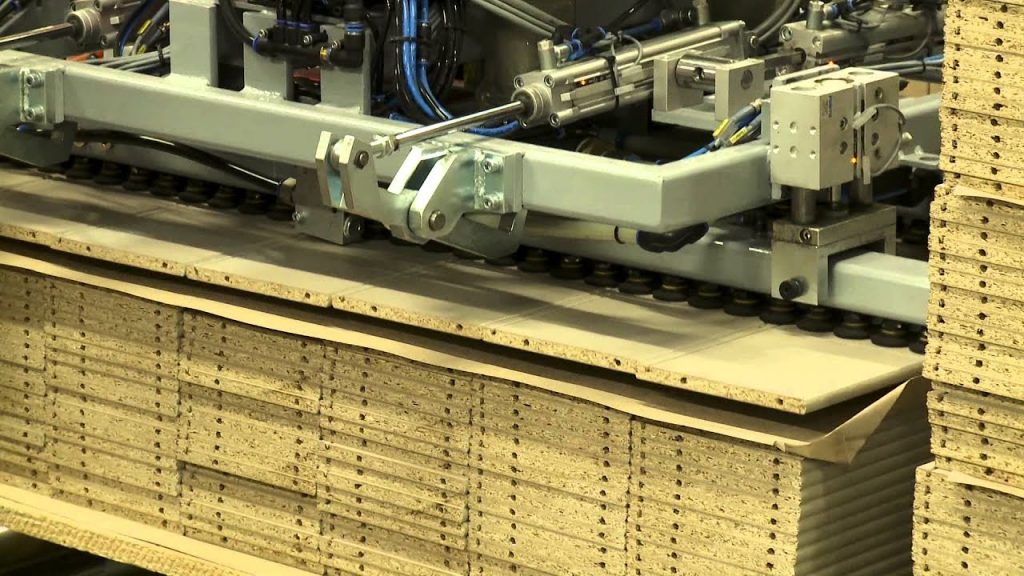

Welcome to our informative video showcasing the exceptional capabilities of the Industrial Packing Line, specifically the innovative IKEA Robot packaging line developed by Teamster AB & Teamster Packaging Systems. This cutting-edge system offers remarkable flexibility in handling various types of products and ensures seamless and rapid changes in the packaging process.

In this comprehensive video, we dive deep into the functionalities and advantages of the Industrial Packing Line and how the IKEA Robot packaging line revolutionizes the packaging industry.

🔹 Introduction:

We begin with a brief overview of the video's content, highlighting the key takeaways and main points viewers can expect. Get ready to explore the world of efficient and adaptable packaging solutions.

🔹 Video Content:

1. Discover the Industrial Packing Line: We provide a detailed overview of the Industrial Packing Line, its components, and how it streamlines the packaging process. Explore the state-of-the-art technology behind this impressive system.

2. Unveiling the IKEA Robot Packaging Line: Learn about the remarkable features and capabilities of the IKEA Robot packaging line. Witness its flexibility in handling different product types, ensuring an efficient and versatile packaging experience.

3. Enhancing Productivity: Delve into how the Industrial Packing Line and IKEA Robot packaging line enhance productivity in packaging operations. Discover the time-saving benefits and increased efficiency they offer to businesses.

4. Seamless Changes and Adaptability: We highlight the quick changeover capabilities of the Industrial Packing Line, enabling businesses to adapt to different product requirements swiftly. Learn how the IKEA Robot packaging line ensures seamless transitions between various packaging tasks.

5. Key Highlights and Interesting Facts: Uncover fascinating facts about the Industrial Packing Line and the IKEA Robot packaging line that demonstrate their superiority in the packaging industry. Discover how these systems are transforming the way products are packaged.

🔹 Call to Action:

If you found this video informative and insightful, we encourage you to like, subscribe, and share it with others who might benefit from learning about the Industrial Packing Line and the IKEA Robot packaging line. Stay updated with the latest advancements in packaging technology.

🔹 Additional Tags and Keywords:

Industrial Packing Line, IKEA Robot, packaging line, Teamster AB, Teamster packaging systems, flexibility, handling different types of products, quick changes, packaging industry, efficiency, productivity, seamless transitions, adaptable packaging, time-saving, innovative technology.

🔹 Hashtags:

#IndustrialPackingLine #IKEARobotPackagingLine #TeamsterAB #TeamsterPackagingSystems #FlexiblePackaging #EfficientPackaging #PackagingTechnology

Title: Optimizing Efficiency: IKEA Robot Packaging Line Tilter

Introduction:

The following tilter proposal outlines the design and implementation of an automated tilter for the IKEA Robot Packaging Line, developed by Teamster AB. This technology aims to enhance the efficiency of the packaging process by automating the tilting operation, thereby reducing manual labor, increasing productivity, and ensuring consistent and accurate packaging.

Objective:

The primary objective of the tilter for the IKEA Robot Packaging Line is to automate the process of tilting the products, ensuring they are properly positioned for packaging. This system will minimize the need for manual intervention, reducing the risk of human error and enabling the line to operate at peak efficiency.

Features and Benefits:

1. Automated Tilting Mechanism: The tilter will be equipped with advanced robotic arms that can precisely tilt the products to the desired angle, ensuring optimal positioning for packaging.

2. Adjustable Tilt Angles: The tilter will have programmable settings to accommodate various products and packaging requirements. This flexibility will allow it to handle a wide range of items efficiently.

3. Enhanced Efficiency: By automating the tilting process, the tilter will significantly reduce the reliance on manual labor, resulting in increased productivity and reduced turnaround time.

4. Improved Accuracy: The precise control offered by the tilter ensures consistent and accurate tilting, minimizing the risk of misaligned or improperly positioned products. This will lead to improved quality and customer satisfaction.

5. Safety Measures: The tilter will be equipped with safety sensors and emergency stop mechanisms to ensure a safe working environment for operators and prevent any potential accidents or injuries.

6. Integration with Existing Systems: The tilter will be seamlessly integrated with the IKEA Robot Packaging Line, allowing for smooth communication and synchronization. It will be designed to interface with the line's control system and work in harmony with other components.

Conclusion:

By incorporating an automated tilter into the IKEA Robot Packaging Line, Teamster AB aims to revolutionize the packaging process. This innovative technology will enhance efficiency, accuracy, and safety while reducing manual labor requirements. The tilter will help optimize the packaging line's performance, enabling Teamster AB to meet the growing demands of IKEA and other customers. Automatic Packing Line

#IKEA #Robot #packaging #line #Teamster