Title: High-Performance Automatic Packaging Line | Schubert's Precise Pick and Place System for Biscuits

Description:

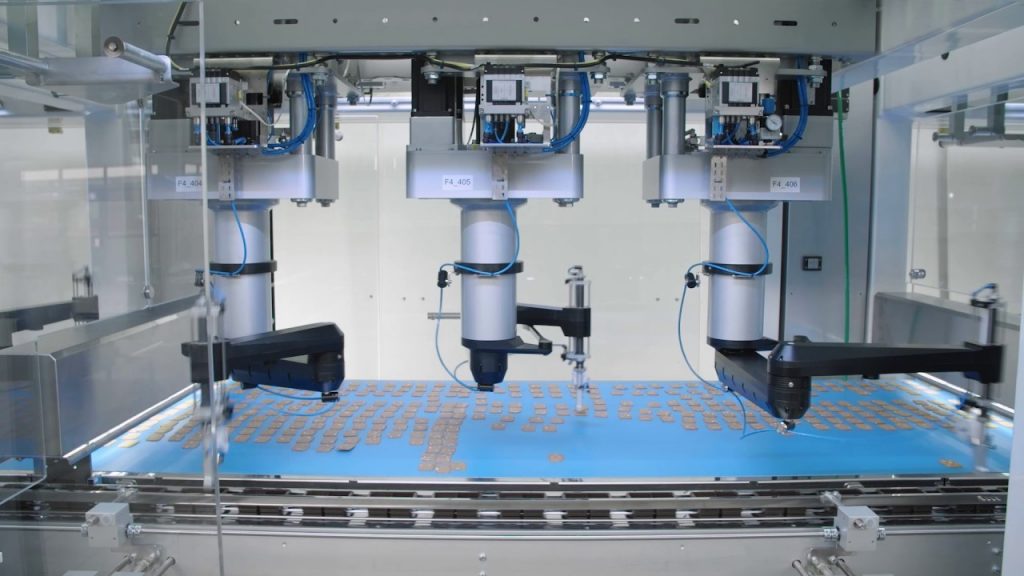

Welcome to our video showcasing the exceptional precision and high-performance capabilities of Schubert's Automatic Packaging Line. In this video, we highlight how our pick and place packaging line efficiently loads biscuits into trays, providing a product-friendly solution for our esteemed Belgian customer, Destrooper-Olivier.

Introduction:

Discover the cutting-edge technology behind Schubert's Automatic Packaging Line, designed to meet the stringent demands of the food industry. With a focus on precision, product-friendliness, and high-performance, this system revolutionizes the packaging process for biscuits.

Video Content:

1. Exceptional Precision: Witness the unrivaled accuracy of the pick and place packaging line as it flawlessly handles biscuits, ensuring each one is placed precisely into trays. This precision guarantees the preservation of the biscuit's integrity and aesthetics.

2. Product-Friendly Solution: Schubert's innovative system takes utmost care of the biscuits, ensuring gentle handling throughout the packaging process. By minimizing product contact and utilizing advanced technology, it safeguards the quality and appearance of the biscuits.

3. High-Performance Efficiency: Explore the impressive speed and efficiency of Schubert's Automatic Packaging Line, as it seamlessly processes large quantities of biscuits. This system optimizes production output, meeting the demands of high-volume production environments.

Operation Steps:

1. Biscuit Loading: Witness the well-coordinated movement of the packaging line, as biscuits are accurately loaded onto the system for further processing.

2. Pick and Place: Experience the precise pick and place mechanism in action, as the system carefully selects each biscuit and positions it perfectly into trays.

3. Tray Arrangement: Observe the meticulous arrangement of the trays, ensuring optimal space utilization and secure packaging.

4. Packaging Completion: Learn about the final steps of the packaging process, as the trays are sealed and prepared for distribution.

Call to Action:

If you found our video informative and impressive, please consider liking, subscribing, and sharing it with others who may benefit from this technological advancement. Stay updated with our latest innovations in packaging solutions by subscribing to our channel.

Additional Tags and Keywords:

automatic packaging line, pick and place packaging, Schubert, biscuits, trays, precision, product-friendly, high-performance, Belgian customer, Destrooper-Olivier, packaging process, cutting-edge technology, gentle handling, efficiency, operation steps, food industry, high-volume production, innovation.

Hashtags:

#AutomaticPackagingLine #PickAndPlacePackaging #Schubert #BiscuitPackaging #ProductFriendly #HighPerformance #Precision #Efficiency #Innovation

Title: Automated Pick and Place Packaging Line for Biscuit Trays by Schubert

Introduction:

The Pick and Place Packaging Line developed by Schubert is a state-of-the-art solution for efficiently loading biscuits into trays. This automated system offers high-speed, precision, and flexibility to meet the demands of modern packaging operations. With its advanced technology and intelligent features, the Schubert Pick and Place Packaging Line revolutionizes the biscuit packaging process.

Features and Benefits:

1. High-Speed Operation:

The Schubert Pick and Place Packaging Line is designed to handle high volumes of biscuits with incredible speed. It ensures continuous production flow and significantly increases packaging efficiency, reducing downtime and maximizing output.

2. Precise and Gentle Handling:

The system utilizes advanced robotics and intelligent algorithms to delicately handle biscuits during the pick and place process. This ensures minimal breakage or damage to the biscuits, maintaining their quality and appearance throughout the packaging operation.

3. Flexibility and Customization:

The Pick and Place Packaging Line can be easily configured to accommodate various tray sizes, shapes, and biscuit types. Its modular design allows for quick and effortless adjustments, ensuring seamless integration into existing packaging lines and adaptability to changing production requirements.

4. Integrated Vision System:

Equipped with a cutting-edge vision system, the Schubert Pick and Place Packaging Line accurately identifies and aligns biscuits for precise placement in the trays. This technology ensures consistent positioning and arrangement, enhancing the overall presentation of the products.

5. User-Friendly Interface:

The line features an intuitive and user-friendly interface, enabling operators to monitor and control the entire packaging process effortlessly. The interface provides real-time data and diagnostics, allowing for quick troubleshooting and optimization of the system's performance.

6. Hygienic Design:

Schubert understands the importance of maintaining strict hygiene standards in the food industry. The Pick and Place Packaging Line is designed with easy-to-clean surfaces and materials that comply with stringent sanitary regulations. This ensures product safety and minimizes the risk of contamination.

Conclusion:

The Schubert Pick and Place Packaging Line offers a cutting-edge solution for efficiently and precisely loading biscuits into trays. With its high-speed operation, gentle handling, flexibility, integrated vision system, user-friendly interface, and hygienic design, this automated system revolutionizes the biscuit packaging process. By implementing this advanced technology, manufacturers can streamline their operations, increase productivity, and deliver high-quality packaged biscuits to the market. Automatic Packing Line

#Pick #place #packaging #line #Schubert #loads #biscuits #trays