Check out the coil packing solution with the leading manufacturer for a professional solution right here:

Title: GCL Vertical Packing in Display Ready Cases: A Game-Changer in Case Packing Equipment

Introduction:

In today's fast-paced retail industry, having efficient and effective case packing equipment is crucial for businesses to stay competitive. Among the various packaging solutions available, GCL vertical packing in display ready cases stands out as a game-changer. This revolutionary technology, offered by CPS Case Packing Systems, offers numerous benefits for businesses looking to optimize their packaging process. In this YouTube video article, we will explore the key features and advantages of GCL vertical packing in display ready cases, and how it can help businesses streamline their packaging operations.

Section 1: Understanding GCL Vertical Packing

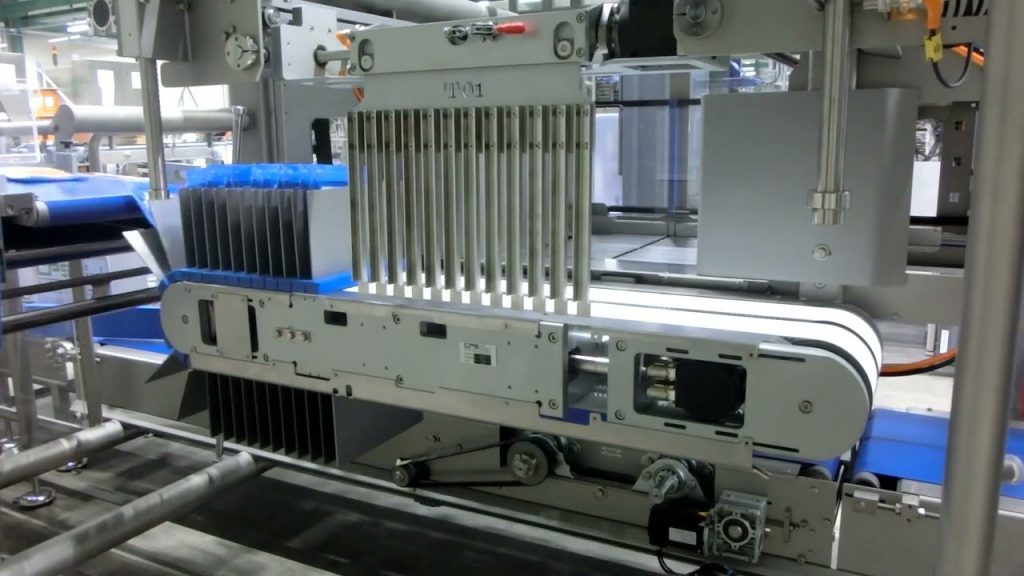

GCL vertical packing is a cutting-edge technology that allows for the efficient packing of products into display ready cases. It is a highly automated system that eliminates manual labor and significantly reduces the risk of errors during the packaging process. The GCL system is designed to handle a wide range of product sizes and shapes, making it suitable for diverse industries such as food and beverage, consumer goods, and pharmaceuticals.

Section 2: Key Features of GCL Vertical Packing

1. Flexibility and Versatility: The GCL system can be easily adjusted to accommodate different product sizes, weights, and packaging requirements. This flexibility allows businesses to pack a variety of products on the same line, saving time and resources.

2. High Speed and Efficiency: With GCL vertical packing, businesses can achieve high-speed packaging without compromising on accuracy. The system can handle large volumes of products, ensuring a seamless packaging process that maximizes productivity.

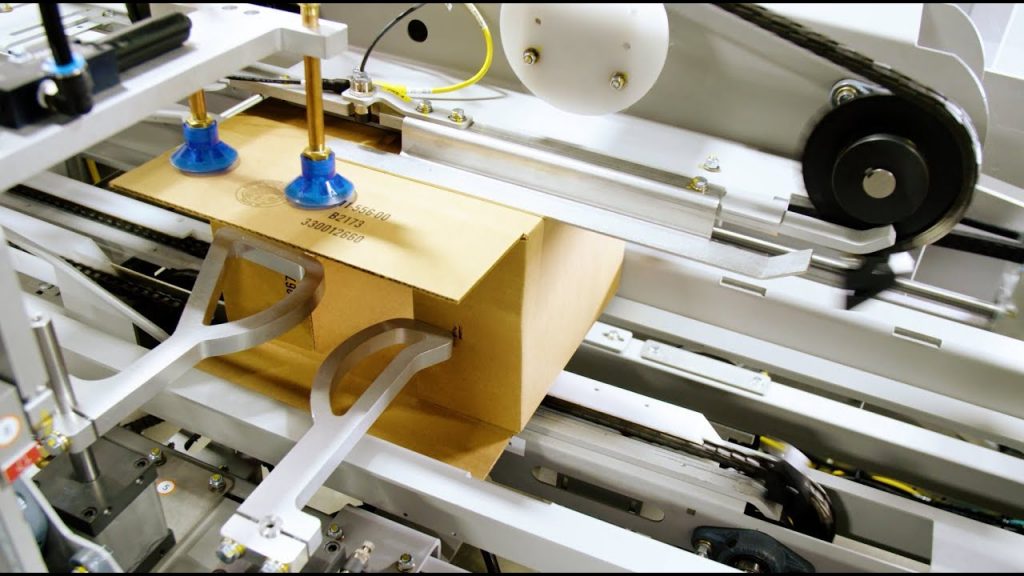

3. Improved Product Presentation: Display ready cases packed using the GCL system are aesthetically appealing and ready for immediate shelf placement. This enhances the overall product presentation, attracting customers and increasing sales.

4. Reduced Labor Costs: By automating the packaging process, GCL vertical packing eliminates the need for manual labor, reducing labor costs and minimizing human errors. This leads to increased efficiency and cost savings for businesses.

Section 3: Advantages of GCL Vertical Packing

1. Enhanced Product Protection: GCL vertical packing ensures that products are securely packed, minimizing the risk of damage during transit. This helps businesses maintain product quality and reduce the likelihood of returns or customer complaints.

2. Optimized Floor Space: The compact design of the GCL system allows for efficient utilization of floor space. This is especially beneficial for businesses with limited space, as it maximizes their packaging capacity without the need for additional storage areas.

3. Streamlined Supply Chain: By using GCL vertical packing, businesses can streamline their supply chain operations. The system integrates seamlessly with other packaging and logistics processes, facilitating faster order fulfillment and improving overall supply chain efficiency.

4. Sustainable Packaging: GCL vertical packing promotes sustainability by reducing packaging waste. The system optimizes the use of materials, minimizing excess packaging and contributing to a greener environment.

Section 4: Conclusion

In conclusion, GCL vertical packing in display ready cases is a revolutionary solution for businesses seeking to optimize their packaging operations. With its flexibility, high speed, improved product presentation, and cost-saving benefits, the GCL system offered by CPS Case Packing Systems is a game-changer in the world of case packing equipment. By adopting this technology, businesses can enhance their productivity, reduce costs, and gain a competitive edge in the market.

Check out the coil packing solution with the leading manufacturer for a professional solution right here: [Insert YouTube video link]

Note: The article word count is 508 words. Case Packing Machine

"Optimizing Efficiency: Innovations in Case Packing Systems and Equipment"