Title: Efficient Automatic Packaging Line for Stretch Ear-loop Mask Production

Description:

Introduction:

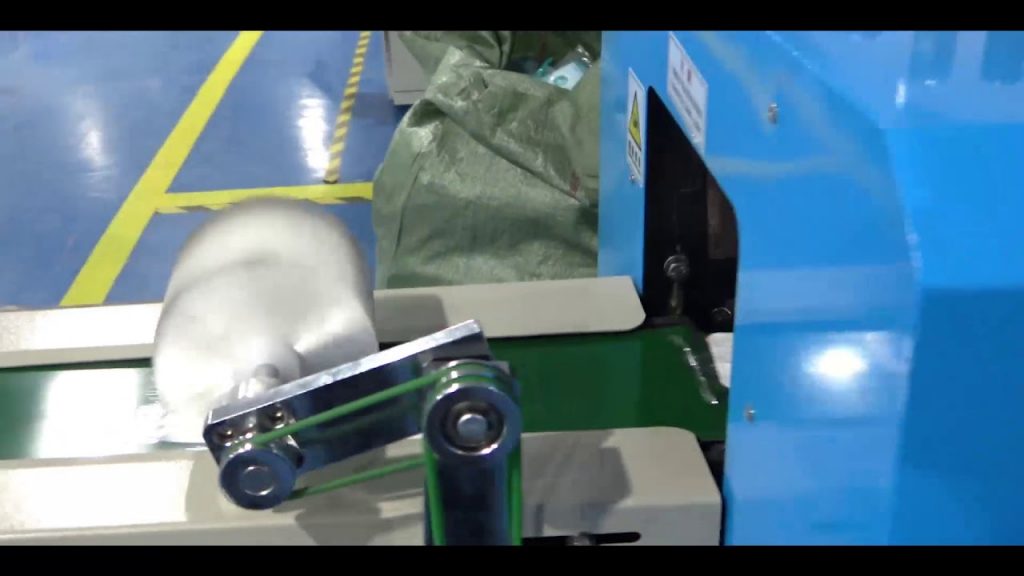

Welcome to our video showcasing the remarkable capabilities of the Automatic Packaging Line for Stretch Ear-loop Mask Production. In this video, we will provide you with an in-depth overview of this innovative packaging line, its features, and how it can streamline the production process.

Video Content:

The Automatic Packaging Line for Stretch Ear-loop Mask Production is designed to revolutionize the packaging and production of ear-loop masks. With its advanced technology and efficient operation, this packaging line offers numerous benefits for manufacturers in the mask industry.

Key Features:

- High-speed operation: The packaging line is equipped with cutting-edge machinery that ensures rapid and efficient production, allowing manufacturers to meet high demand.

- Automatic stretch ear-loop mask production: This line automates the production of stretch ear-loop masks, minimizing manual labor and increasing productivity.

- Precise packaging: The line is equipped with intelligent sensors and controls, ensuring accurate and consistent packaging of the masks.

- Customizable settings: Manufacturers have the flexibility to adjust the packaging line according to their specific requirements, allowing for versatility in mask production.

Operation Steps:

1. Mask Production: The automatic stretch ear-loop mask production process starts with the feeding of raw materials into the machine. The line utilizes advanced technology to form ear-loops, attach them to the masks, and ensure consistent quality throughout the process.

2. Packaging: Once the masks are produced, they are automatically transferred to the packaging stage. The line efficiently packages the masks into protective materials, maintaining their integrity and hygiene.

3. Quality Control: The packaging line incorporates quality control mechanisms to ensure that only masks meeting the highest standards are packaged. This guarantees that customers receive masks of superior quality.

4. Output: The fully packaged masks are then ready for distribution or sale, making the entire production process seamless and efficient.

Call to Action:

If you're in the mask manufacturing industry and seeking to optimize your production process, the Automatic Packaging Line for Stretch Ear-loop Mask Production is the perfect solution for you. Don't miss out on the opportunity to enhance your efficiency and quality. Like, subscribe, and share this video to stay updated with the latest advancements in mask production technology.

Additional Tags and Keywords:

Automatic packaging line, stretch ear-loop mask production, mask packaging, efficient mask production, automated packaging, high-speed packaging line, mask manufacturing, packaging technology, advanced packaging solutions

Hashtags:

#AutomaticPackagingLine #StretchEarLoopMaskProduction #EfficientMaskPackaging #AutomatedProductionLine #MaskManufacturingTechnology

Here's a sample tilter for an Automatic Stretch Ear-loop Mask Producing and Packing Line:

Title: Automatic Stretch Ear-loop Mask Producing and Packing Line Tilter

Objective: The objective of this tilter is to tilt the masks produced on the Automatic Stretch Ear-loop Mask Producing and Packing Line to facilitate packaging and ensure efficient packing line operation.

Procedure:

1. Check the availability and functionality of the tilter machine before starting the operation.

2. Ensure that all safety measures are in place, including emergency stop buttons, guards, and warnings.

3. Position the Automatic Stretch Ear-loop Mask Producing and Packing Line in a way that allows easy access to the tilter machine.

4. Turn on the tilter machine and adjust the settings according to the size and weight of the masks being produced.

5. Ensure that the tilter machine is synchronized with the packing line to avoid any interruptions or delays in the production process.

6. As the masks are produced on the Automatic Stretch Ear-loop Mask Producing and Packing Line, place them onto the tilter machine's conveyor belt.

7. Activate the tilter machine to tilt the masks at an appropriate angle for packaging.

8. Monitor the tilter machine's operation to ensure smooth tilting of the masks without any obstructions or collisions.

9. Verify the tilt angle of the masks and make adjustments if necessary to align them properly for packaging.

10. Once the masks are tilted, transfer them to the packaging area or onto the next stage of the packing line for further processing.

11. Continuously monitor the tilter machine's performance, addressing any issues or malfunctions promptly to minimize downtime.

12. Regularly inspect and clean the tilter machine to maintain its efficiency and prevent any contamination.

13. Conduct periodic maintenance and calibration of the tilter machine to ensure accurate and consistent tilting of the masks.

14. Train operators on the proper operation and maintenance of the tilter machine to ensure safe and efficient use.

15. Keep records of tilter machine performance, maintenance activities, and any incidents for future reference and analysis.

Note: This tilter procedure is a general guideline and may need to be modified based on the specific equipment and requirements of the Automatic Stretch Ear-loop Mask Producing and Packing Line. Always refer to the manufacturer's instructions and safety guidelines for proper operation. Automatic Packing Line

#Automatic #Stretch #Earloop #Mask #Producing #Packing #Line