Title: Automatic Handling Machine, Suntech Automatic Fabric Cutting and Taping Machine & Newly Developed Automatic Fabric Inspection, Labeling, Cutting, Taping, and Packing Machine - Overview and Operation Steps

Description:

Introduction:

Welcome to our video showcasing the remarkable capabilities of the Automatic Handling Machine, Suntech Automatic Fabric Cutting and Taping Machine, and the Newly Developed Automatic Fabric Inspection, Labeling, Cutting, Taping, and Packing Machine. In this video, we will provide a comprehensive overview of these innovative machines, highlighting their features, benefits, and operational steps.

Video Content:

1. Automatic Handling Machine:

The Automatic Handling Machine revolutionizes the fabric handling process, offering seamless automation and increased efficiency. This machine streamlines various fabric-related tasks, including inspection, labeling, cutting, taping, and packing. With its advanced technology and precise functionality, it significantly reduces human effort and saves valuable time.

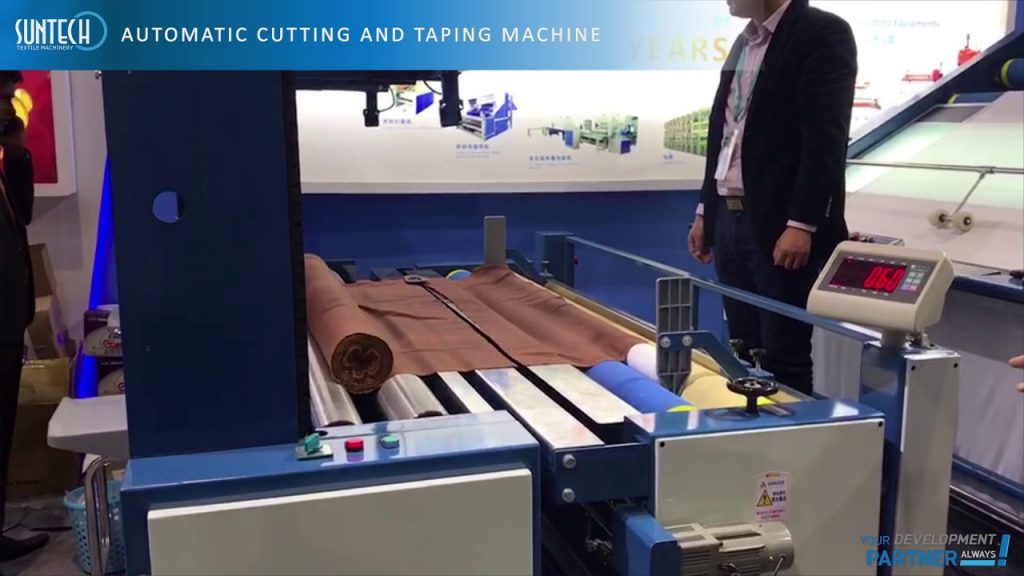

2. Suntech Automatic Fabric Cutting and Taping Machine:

The Suntech Automatic Fabric Cutting and Taping Machine is a cutting-edge solution designed for precise and efficient fabric cutting and taping. Its state-of-the-art features and user-friendly interface make it an indispensable tool for fabric manufacturers and textile industries. This machine ensures accuracy, consistency, and high productivity in the cutting and taping process.

3. Newly Developed Automatic Fabric Inspection, Labeling, Cutting, Taping, and Packing Machine:

Our newly developed machine combines multiple fabric handling functions into a single, fully automated system. This machine incorporates advanced fabric inspection technology with high-resolution cameras, ensuring quality control and defect detection. Additionally, it integrates labeling, cutting, taping, and packing processes, providing a comprehensive solution for fabric handling requirements.

Operation Steps:

- Step 1: Fabric Inspection and Defect Detection

Our automatic fabric inspection system utilizes cutting-edge cameras to examine the fabric's surface for any defects, ensuring only flawless pieces proceed to further processing.

- Step 2: Labeling

The machine applies labels with precision, enabling easy identification and tracking throughout the fabric handling process.

- Step 3: Cutting

With its precise cutting mechanism, the machine cuts the fabric according to the desired dimensions, ensuring accuracy and consistency.

- Step 4: Taping

The taping process adds reinforcement and finishing touches to the fabric, enhancing its durability and aesthetics.

- Step 5: Packing

The machine efficiently packs the fabric, ready for distribution or storage, ensuring optimal utilization of space and protection during transportation.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with others who might benefit from this innovative fabric handling technology. Stay tuned for more exciting updates and demonstrations of our cutting-edge machines.

Additional Tags and Keywords:

Automatic Handling Machine, Fabric Cutting and Taping Machine, Automatic Fabric Inspection, Labeling Machine, Packing Machine, Fabric Handling, Textile Industry, Automation, Efficiency, Quality Control, Defect Detection, Precision Cutting, Taping Process, Packaging Solutions, Innovation.

Hashtags:

#AutomaticHandlingMachine #FabricCuttingTapingMachine #FabricInspection #LabelingMachine #PackingMachine #TextileIndustry #FabricHandling #Automation #QualityControl #Innovation

Here is a sample tilter for the Suntech Automatic Fabric Cutting and Taping Machine:

Title: Suntech Automatic Fabric Cutting and Taping Machine Tilter

Introduction:

The Suntech Automatic Fabric Cutting and Taping Machine is a state-of-the-art equipment designed to streamline fabric cutting and taping processes. With its advanced features and precision, this machine has revolutionized the textile industry. In this tilter, we will delve into the key features, benefits, and applications of the Suntech Automatic Fabric Cutting and Taping Machine.

1. Key Features:

- Automatic cutting and taping: The machine combines cutting and taping functions, eliminating the need for separate equipment and reducing processing time.

- High precision cutting: Equipped with advanced sensors and cutting mechanisms, it ensures accurate and clean cuts, minimizing fabric waste.

- Adjustable cutting length: Users can easily set the desired cutting length, allowing for customization and versatility in various fabric applications.

- User-friendly interface: The intuitive control panel enables effortless operation, making it suitable for both experienced and novice operators.

- Efficient tape application: The machine's taping feature applies adhesive tape evenly and consistently, ensuring strong and reliable fabric joins.

2. Benefits:

- Increased productivity: The automation and precision offered by the Suntech Automatic Fabric Cutting and Taping Machine significantly enhance productivity, reducing labor costs and improving overall efficiency in fabric processing.

- Cost-effective: By minimizing fabric waste and optimizing tape usage, this machine helps manufacturers save on material costs, making it a cost-effective investment.

- Enhanced product quality: The machine's accurate cutting and consistent tape application result in high-quality fabric products, meeting the stringent standards of the textile industry.

- Time-saving: With its automatic functions, the machine eliminates the need for manual cutting and taping, saving valuable time and allowing operators to focus on other tasks.

- Versatile application: The Suntech Automatic Fabric Cutting and Taping Machine can be used in various industries, including clothing manufacturing, upholstery, automotive, and more.

3. Applications:

- Apparel industry: The machine is ideal for cutting and taping fabric pieces used in garment production, ensuring precise and durable joins.

- Home textiles: It can be used to cut and tape fabrics for curtains, bedspreads, tablecloths, and other household textiles, guaranteeing a professional finish.

- Automotive industry: The Suntech Automatic Fabric Cutting and Taping Machine simplifies the process of cutting and taping fabric used in vehicle interiors, such as seat covers and headliners.

- Upholstery: With its ability to handle a wide range of fabrics, this machine is suitable for cutting and taping materials used in furniture upholstery, providing reliable and long-lasting joins.

Conclusion:

The Suntech Automatic Fabric Cutting and Taping Machine is a game-changer in the textile industry, offering advanced features, cost-effectiveness, and increased productivity. With its precise cutting and consistent tape application, this machine ensures high-quality fabric products across various applications. Investing in the Suntech Automatic Fabric Cutting and Taping Machine can greatly benefit textile manufacturers, enabling them to streamline their operations and stay ahead in a competitive market.Handling Machine

#Suntech #Automatic #Fabric #Cutting #Taping #Machine