Heat Shrinking Machine: A Comprehensive Guide to POF Film Sealing and Heat Shrinking

Introduction:

Heat shrinking machines have revolutionized the packaging industry by providing efficient and cost-effective solutions for product packaging. These machines are widely used in various industries, including food and beverages, pharmaceuticals, electronics, and more. In this article, we will delve into the intricacies of heat shrinking machines, focusing on their functionality, benefits, and applications. Additionally, we will explore the use of POF film for sealing and heat shrinking, shedding light on its advantages and suitability for different packaging needs.

I. Understanding Heat Shrinking Machines:

Heat shrinking machines, also known as shrink wrap machines, are designed to wrap products tightly in a protective plastic film. This film, typically made of polyolefin or PVC, is then heated, causing it to shrink and conform to the shape of the product. The heat shrinking process not only secures the product but also enhances its appearance, providing a professional and appealing finish.

A. Types of Heat Shrinking Machines:

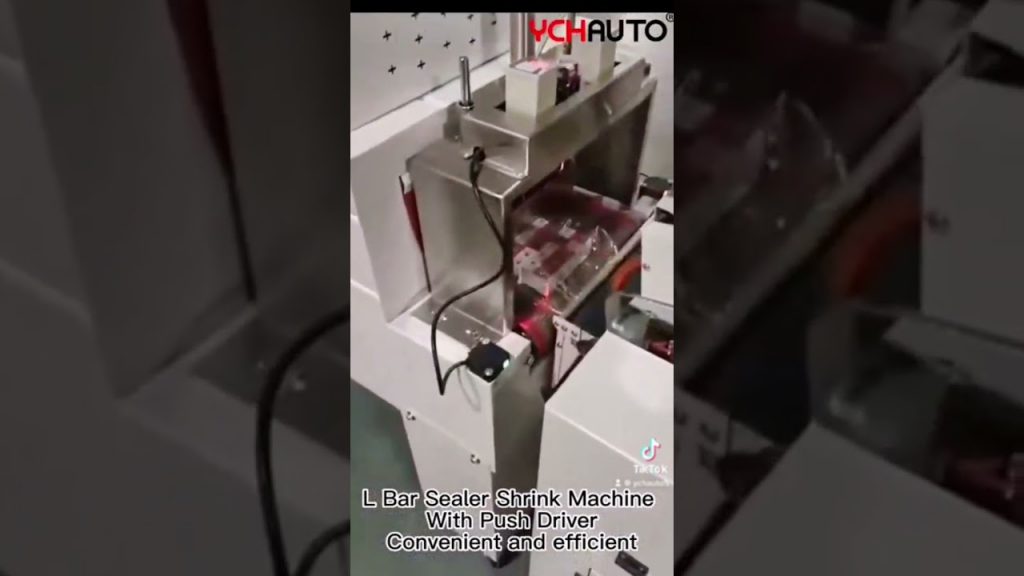

1. L-Bar Sealers: L-bar sealers are versatile machines that can accommodate a wide range of product sizes and shapes. They use a sealing bar to create a seal around the product before it is exposed to heat for shrinking. L-bar sealers are ideal for packaging individual products or small batches.

2. Chamber Machines: Chamber machines are suitable for packaging larger products or bulk quantities. These machines enclose the product and the film in a chamber, where heat is applied to shrink the film. Chamber machines are commonly used in industries that require high-volume packaging.

B. Benefits of Heat Shrinking Machines:

1. Protection: Heat shrinking machines provide a protective barrier around the product, safeguarding it against dust, moisture, and physical damage during transit or storage.

2. Tamper-Evident Packaging: Heat shrinking creates a sealed package that is tamper-evident. Any attempt to open or tamper with the package will be visible, ensuring the integrity of the product.

3. Enhanced Presentation: The tight and neat wrapping achieved through heat shrinking enhances the visual appeal of the product. This is particularly important for retail products, where presentation plays a crucial role in attracting customers.

4. Cost-Effective: Heat shrinking machines offer a cost-effective packaging solution, as they eliminate the need for additional packaging materials such as boxes or cartons. The use of a single film for wrapping multiple products reduces material costs.

II. POF Film for Sealing and Heat Shrinking:

POF (Polyolefin) film is commonly used in heat shrinking machines due to its excellent shrinkability and versatility. POF film is a type of plastic film that becomes pliable when heated, allowing it to conform to the shape of the product. It offers several advantages over other packaging materials:

A. Clarity: POF film provides exceptional clarity, ensuring that the product is visible through the wrapping. This is particularly advantageous for products that rely on visual appeal for marketing.

B. Strength and Durability: POF film is known for its strength and durability, offering protection to the packaged product during transport and storage. It resists tearing and puncturing, reducing the risk of damage.

C. Versatility: POF film can be used for packaging a wide range of products, including irregularly shaped items. Its flexibility and shrinkability enable it to conform to intricate shapes, ensuring a tight and secure wrap.

D. Environmentally Friendly: POF film is recyclable, making it an environmentally friendly packaging option. It is free from harmful chemicals and does not emit toxic fumes when heated.

III. Applications of Heat Shrinking Machines and POF Film:

Heat shrinking machines, coupled with POF film, find applications in various industries:

A. Food and Beverages: Heat shrinking machines are widely used in the food and beverage industry for packaging products such as bottles, cans, and food containers. The tamper-evident packaging provided by heat shrinking ensures the safety and integrity of the packaged food or beverage.

B. Pharmaceuticals: Heat shrinking machines play a crucial role in the pharmaceutical industry, where the packaging of medicines and medical devices requires strict adherence to quality standards. The tamper-evident feature of heat-shrunk packaging ensures the authenticity of the products.

C. Electronics: Heat shrinking machines are used in the electronics industry for packaging components, cables, and electronic devices. The tight and secure wrap provided by heat shrinking protects sensitive electronic equipment from dust, moisture, and physical damage.

Conclusion:

Heat shrinking machines, in combination with POF film, offer a reliable and efficient packaging solution for various industries. The benefits of heat shrinking, including protection, tamper-evident packaging, enhanced presentation, and cost-effectiveness, make it a preferred choice for many businesses. POF film further enhances the packaging process by providing clarity, strength, versatility, and eco-friendliness. Whether you are in the food and beverage, pharmaceutical, or electronics industry, heat shrinking machines can streamline your packaging operations and ensure the safety and integrity of your products.

Check the coil packing solution with a leading manufacturer for professional solutions just here. Shrinking Machine

"Efficient Film Sealing and Heat Shrinking Machine: Boost Packaging Quality and Speed"