Labeling Machine Manufacturers" sentence and use the keyword "Flat Labeling Machine" in the last paragraph of the article.

Title: Enhancing Efficiency and Precision: The Work of a Labeling Machine

Introduction:

Labeling machines play a crucial role in the packaging industry, ensuring products are transported and labeled accurately according to specific rules. In this article, we will delve into the functionality and benefits of labeling machines, exploring their role in streamlining operations for manufacturers. Whether you are a business owner seeking to optimize your packaging process or simply curious about the inner workings of these machines, this article will provide valuable insights.

Explanatory Style:

Labeling machines are designed to transport products in a specific order and apply labels with utmost precision. These machines employ advanced sensors that detect the products, ensuring accurate positioning for labeling. By automating this process, manufacturers can achieve higher efficiency and reduce human error.

The labeling process begins when the sensor detects a product approaching the machine. Once detected, the product is carefully positioned to receive the label. The labeling machine then applies the label accurately, ensuring it adheres to the product with precision. This automation eliminates the need for manual labeling, saving time and labor costs.

The use of labeling machines offers numerous benefits for manufacturers. Firstly, it significantly improves productivity by streamlining the packaging process. With the ability to label products at a rapid pace, businesses can meet high demand and increase their output. Additionally, labeling machines ensure consistent label placement, enhancing the overall appearance and professionalism of the packaged products.

One of the key advantages of labeling machines is their versatility. These machines can handle various shapes, sizes, and types of products, making them suitable for a wide range of industries. From food and beverage to pharmaceuticals and cosmetics, labeling machines prove invaluable in packaging diverse products efficiently.

In-depth Analysis Style:

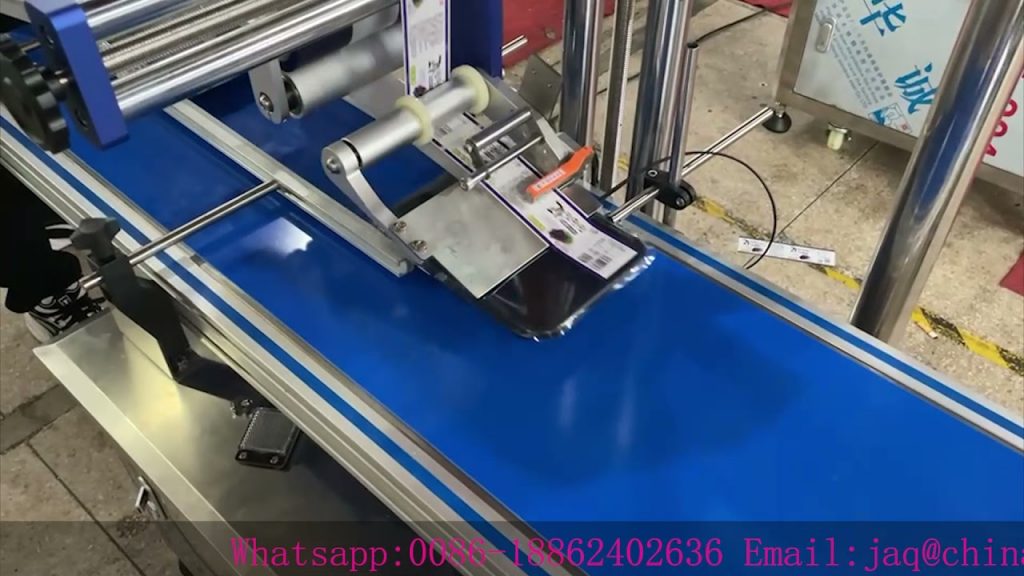

Labeling machines can be categorized into different types based on their functionality. One of the most commonly used types is the flat labeling machine. This machine excels in labeling flat surfaces, such as boxes, cartons, and packets. Its versatility and precision make it an ideal choice for industries where flat packaging is prevalent.

The flat labeling machine operates by feeding the products onto a conveyor belt. As the products move along the belt, the labeling machine carefully dispenses the labels onto the designated areas. The labels adhere seamlessly to the flat surfaces, ensuring a professional and visually appealing finish.

The accuracy and efficiency of flat labeling machines are further enhanced by their advanced control systems. These machines can be programmed to apply labels at specific intervals, ensuring consistent label placement. Additionally, some models offer features such as automatic label detection and adjustment, minimizing label wastage and optimizing productivity.

Conclusion:

Labeling machines have revolutionized the packaging industry by significantly improving efficiency and precision. These machines, such as the flat labeling machine, offer manufacturers a reliable and versatile solution for labeling flat surfaces accurately. By automating the labeling process, businesses can streamline their operations, increase productivity, and enhance the overall quality of their packaged products.

Check the coil packing solution with leading manufacturer for the professional solution just here: Labeling Machine Manufacturers. Whether you need a flat labeling machine or other types of labeling machines, these manufacturers can provide you with the perfect solution tailored to your specific needs. Labeling Machine

"Efficient Labeling Solutions for Various Products: Unveiling the Modern Flat Labeling Machine Technology"