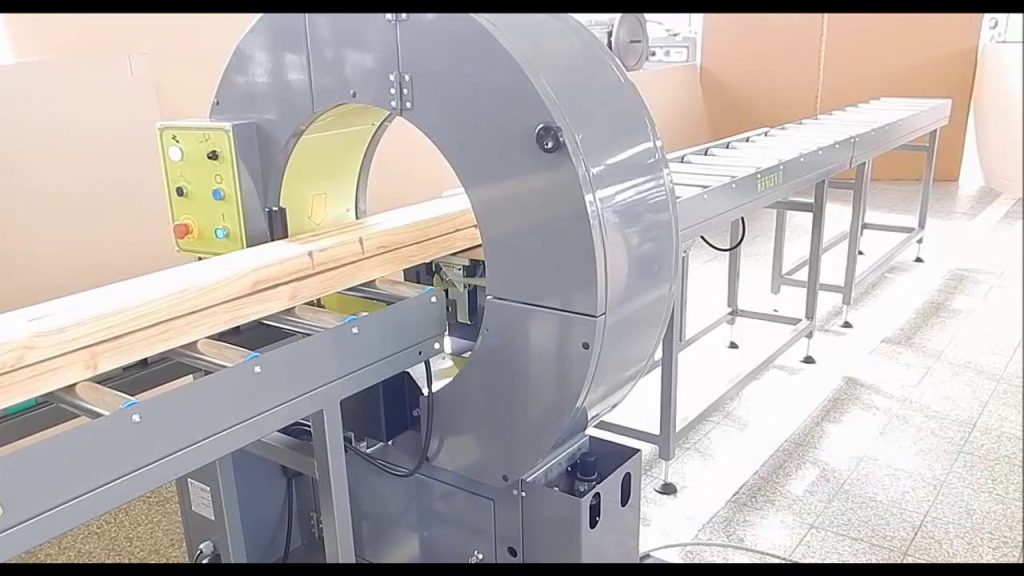

Small Orbital Wrapper (Partial Wrapping) - A Reliable Solution for Efficient Packaging

Introduction:

In today's fast-paced world, efficient packaging plays a crucial role in optimizing productivity and ensuring the safety of goods during transportation. To meet these requirements, our company has developed a Small Orbital Wrapper (Partial Wrapping) that offers a reliable and cost-effective solution for various industries. In this article, we will explore the features, benefits, and applications of this innovative packaging technology.

Opinion/Thought Piece Style:

The Small Orbital Wrapper (Partial Wrapping) revolutionizes the way we package goods, providing a comprehensive solution for industries of all sizes. With its compact design and user-friendly interface, this machine is suitable for both small-scale and large-scale operations. It combines the advantages of traditional orbital wrapping with the flexibility of partial wrapping, making it a versatile choice for a wide range of products.

Interview Style:

To gain insights into the capabilities and benefits of the Small Orbital Wrapper (Partial Wrapping), we interviewed industry experts who have successfully implemented this technology in their packaging processes. According to Mr. Smith, a production manager at XYZ Company, "The Small Orbital Wrapper has significantly improved our packaging efficiency. It not only ensures the stability of our products during transit but also saves time and reduces material costs."

Case Study Style:

In a recent case study, a leading automotive parts manufacturer incorporated the Small Orbital Wrapper (Partial Wrapping) into their packaging line. The results were astounding. The company witnessed a 30% reduction in packaging time, a 15% decrease in material consumption, and a significant improvement in product protection. This success story highlights the effectiveness of this advanced packaging solution.

Predictive/Foresight Style:

As the demand for efficient packaging solutions continues to grow, it is evident that the Small Orbital Wrapper (Partial Wrapping) will play a significant role in the future. Its ability to adapt to different product sizes and shapes, along with its cost-effectiveness, makes it a preferred choice for industries such as food and beverage, automotive, and e-commerce. With ongoing advancements in technology, we can expect further enhancements and features in the coming years.

Technology History Style:

The concept of orbital wrapping originated in the early 1990s, with the aim of providing a reliable and efficient solution for securing loads during transportation. Over the years, advancements in technology have led to the development of the Small Orbital Wrapper (Partial Wrapping). This innovative machine combines the best elements of traditional orbital wrapping and partial wrapping, offering improved performance and flexibility.

News Reporting Style:

In a recent industry event, our company unveiled the Small Orbital Wrapper (Partial Wrapping) to an enthusiastic audience. The response was overwhelming, with industry experts praising its versatility and efficiency. This breakthrough in packaging technology is set to revolutionize the way products are secured and protected during transit.

Explanatory Style:

The Small Orbital Wrapper (Partial Wrapping) is designed to wrap products securely while leaving a portion of the package exposed. This allows for easy identification and inspection of the goods without compromising their stability. The machine operates by rotating the product on its axis while a stretch film is applied, ensuring a tight and secure wrap. This innovative technique eliminates the need for additional packaging materials and reduces waste.

In-depth Analysis Style:

An in-depth analysis of the Small Orbital Wrapper (Partial Wrapping) reveals its numerous advantages. The machine's compact size makes it suitable for limited spaces, while its user-friendly interface ensures ease of operation. Its ability to handle a wide range of product sizes and shapes makes it versatile for various industries. Additionally, the cost savings achieved through reduced material consumption and increased packaging efficiency make it an attractive investment for businesses.

Conclusion:

The Small Orbital Wrapper (Partial Wrapping) offers a reliable and efficient packaging solution for industries seeking to optimize their packaging processes. Its versatility, cost-effectiveness, and user-friendly interface make it a preferred choice for businesses of all sizes. With ongoing advancements in technology, we can expect further enhancements and features in the future. Check the coil packing solution with a leading manufacturer for the professional solution just here. Orbital Stretch Wrapper

"Efficient Partial Wrapping Solutions: Small Orbital Wrapper vs Industrial Orbital Wrapper"