If you're looking to create two-color products, there are two main methods: over-molding through a 2-step injection process or double injection using a single plastic injection machine. In this YouTube video, we will explore these two techniques and discuss their advantages and applications.

Over-molding by 2-step injection involves injecting the first color material into a mold to create the base layer. Once the base layer has solidified, the second color material is injected over the base layer. This process requires a mold with multiple cavities and a two-step injection machine. The advantage of this method is that it allows for intricate designs and precise color placement. It is commonly used in industries such as automotive, electronics, and consumer goods.

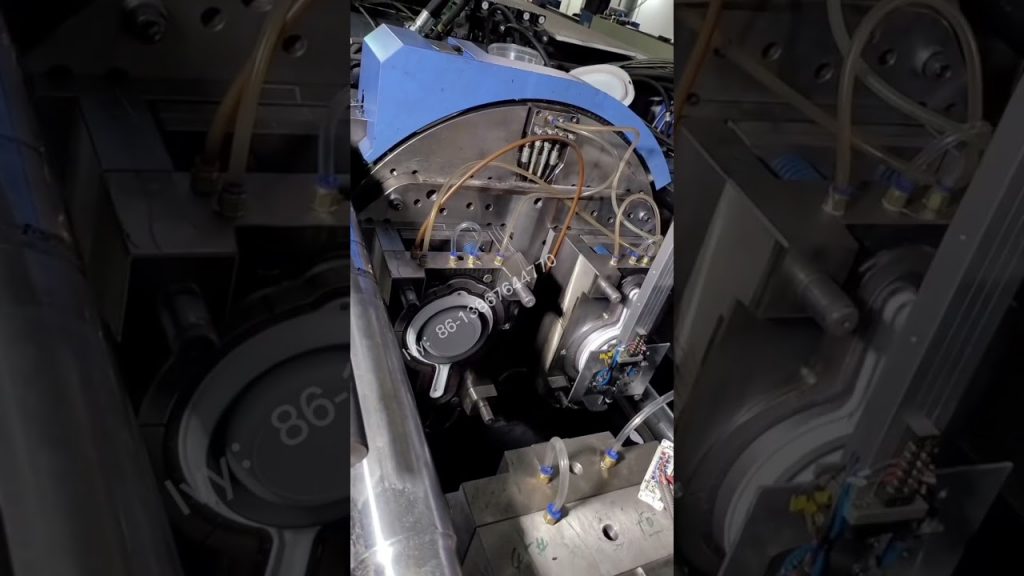

On the other hand, double injection by single plastic injection machine involves injecting two different color materials simultaneously or sequentially into a mold to create a two-color product. This method requires a special two-color injection molding machine that has two injection units. The advantage of this technique is that it offers a faster production cycle and eliminates the need for a separate over-molding process. It is commonly used in industries such as household products, medical devices, and packaging.

Plastic injection machines play a crucial role in both over-molding and double injection processes. These machines are designed to melt and inject plastic materials into molds, allowing for the creation of various plastic products. They come in different sizes and configurations to accommodate different production needs.

One example of a plastic injection machine suitable for two-color molding is the XYZ model. This machine offers precise control over the injection process, ensuring accurate color mixing and distribution. With its advanced features and user-friendly interface, the XYZ model allows for efficient and high-quality production of two-color plastic products.

In the case of double injection for folding kitchenware plastic products, the process involves injecting two different color materials into a mold to create a folding kitchenware item with visually appealing color combinations. The two-color injection molding machine used for this process ensures that the two colors are seamlessly integrated, resulting in a durable and aesthetically pleasing product.

Plastic injection machines have revolutionized the manufacturing industry by enabling the production of complex and customized plastic products. With their versatility and efficiency, these machines have become an essential tool for many industries.

In conclusion, there are two main methods for creating two-color products: over-molding by 2-step injection and double injection by a single plastic injection machine. Both techniques offer unique advantages and are widely used in various industries. Plastic injection machines, such as the XYZ model, play a crucial role in these processes by enabling precise and efficient production. If you're looking to create high-quality two-color plastic products, consider utilizing these innovative techniques and machinery.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Plastic Injection Machine

"Efficient One-Step Injection Molding for Double Color Folding Kitchenware Plastic Products and Plastic Injection Machines"