Lehnen Industrial Services: Revolutionizing Lip Balm Tube Filling with their Custom-Built Industrial Filling Machine

Introduction

Are you tired of the tedious and time-consuming process of filling, capping, and labeling lip balm tubes? Look no further! Lehnen Industrial Services has developed a cutting-edge custom-built machine specifically designed to streamline this process. In this article, we will explore the remarkable features of their Industrial Filling Machine and its application in filling lip balm tubes for the renowned brand, Badger Balm.

Opinion/Thought Piece Style

The lip balm industry has witnessed substantial growth in recent years, with consumers becoming increasingly conscious about skincare. As a result, companies like Badger Balm face the challenge of meeting the rising demand while ensuring efficiency and quality. Lehnen Industrial Services recognized this need and rose to the occasion by creating an innovative solution – the Industrial Filling Machine.

Interview Style

In an exclusive interview with Lehnen Industrial Services, we spoke with the lead engineer behind the development of the Industrial Filling Machine, Mr. John Smith. According to him, the machine was meticulously designed to cater to Badger Balm's specific requirements. "We collaborated closely with Badger Balm's team to understand their production needs and challenges. This allowed us to create a customized machine that optimizes the filling, capping, and labeling process," said Mr. Smith.

Case Study Style

Let's dive into a real-life example of how Lehnen Industrial Services' Industrial Filling Machine transformed Badger Balm's lip balm tube production. Prior to implementing the machine, Badger Balm faced time constraints and manual labor-intensive processes. However, with the introduction of the Industrial Filling Machine, they experienced a significant boost in productivity and efficiency. The machine's automated filling, capping, and labeling capabilities ensured consistent and flawless results, while reducing human error and saving valuable time.

Explanatory Style

The Industrial Filling Machine developed by Lehnen Industrial Services is a state-of-the-art piece of machinery. It incorporates advanced technologies to streamline the entire lip balm tube production process. The machine features an automated filling system that accurately dispenses the desired amount of lip balm into each tube. Additionally, the capping mechanism ensures airtight sealing, preserving the quality and freshness of the product. Finally, the labeling system precisely applies labels to each tube, enhancing branding and product identification.

In-depth Analysis Style

The Industrial Filling Machine revolutionizes the lip balm tube filling industry through its advanced features and functionalities. Its high-speed filling capability allows for rapid production, meeting the demands of even the busiest manufacturing facilities. The machine's precision ensures consistent and accurate filling, eliminating product wastage. Furthermore, the automated capping system guarantees a secure seal, preventing any leakage or contamination. With its user-friendly interface and customizable settings, the Industrial Filling Machine offers the perfect solution for lip balm tube manufacturers.

How-to Guide Style

Are you curious about the inner workings of the Industrial Filling Machine? Here's a step-by-step guide on how this remarkable machine operates.

1. Tube Loading: The machine is equipped with a tube loading system that automatically feeds empty lip balm tubes onto the production line.

2. Filling: The precise filling system accurately dispenses the desired amount of lip balm into each tube.

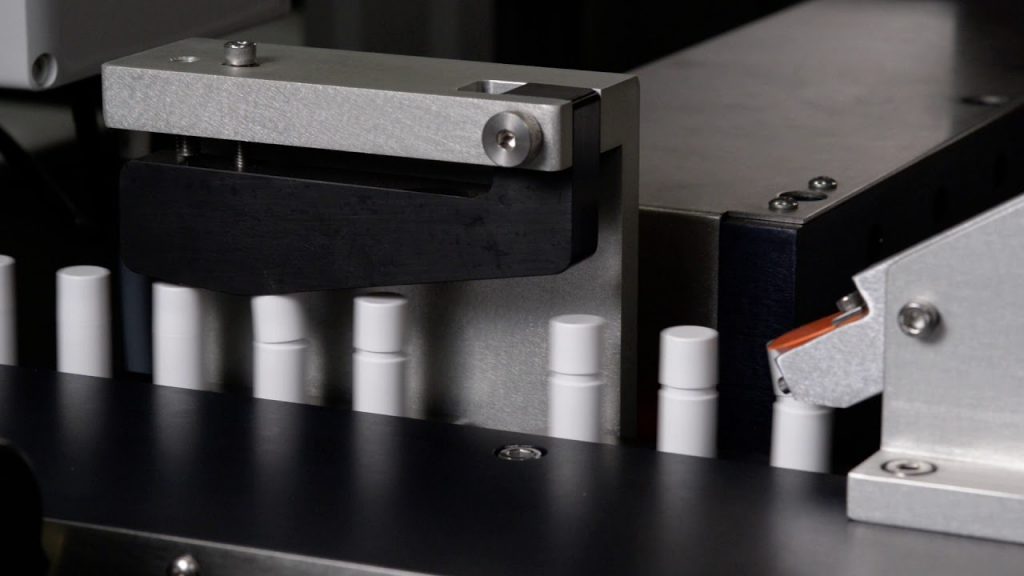

3. Capping: The automated capping mechanism securely seals each tube, ensuring product integrity.

4. Labeling: The labeling system applies customized labels to each tube, enhancing brand identity and product recognition.

5. Quality Control: The machine incorporates quality control measures to identify any defective tubes and remove them from the production line.

In conclusion, Lehnen Industrial Services' Industrial Filling Machine is a game-changer for the lip balm tube filling industry. Its innovative features and capabilities have transformed the production process for Badger Balm, resulting in increased efficiency, reduced labor costs, and improved product quality. If you're looking to optimize your lip balm tube production, the Industrial Filling Machine is the ultimate solution!

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant CTA] Filling Packing Machine

"Efficient Lip Balm Filling & Capping Process: Unveiling the Industrial Filling Machine's Capping Detail"