Check out our website for the best coil packing solutions from a leading manufacturer in the industry.

Title: Revolutionizing Liquid Capsule Filling and Sealing with LCFS 300 Machine

Introduction:

In the fast-paced world of pharmaceuticals and nutraceuticals, efficiency and precision are key. The LCFS 300 Liquid Capsule Filling Sealing Machine is here to revolutionize the process of filling and sealing liquid capsules. With its state-of-the-art technology and innovative design, this machine enables manufacturers to achieve unparalleled speed, accuracy, and reliability in their production line. In this article, we will delve into the features and benefits of the LCFS 300, exploring how it enhances the capsule-in-capsule process and transforms the way liquid capsules are manufactured.

Section 1: The Need for Advanced Filling and Sealing Machines

Before we dive into the details of the LCFS 300, it is important to understand the significance of advanced filling and sealing machines in the industry. With growing consumer demand for liquid capsules, manufacturers are constantly seeking ways to improve their production processes. Traditional methods are time-consuming, prone to human error, and often result in inconsistent capsule quality. This is where the LCFS 300 steps in, offering a game-changing solution.

Section 2: LCFS 300 - A Breakthrough in Liquid Capsule Manufacturing

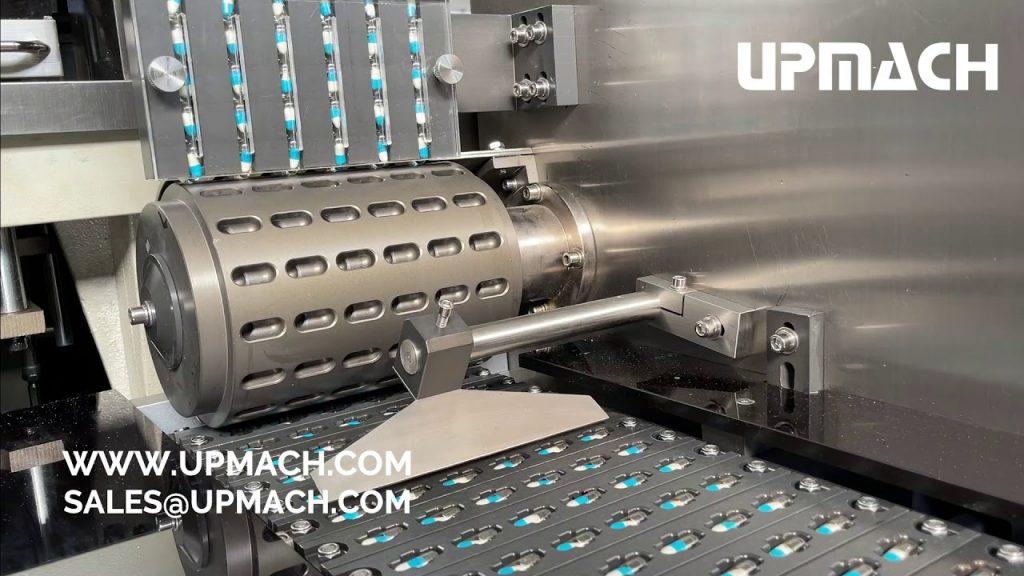

The LCFS 300 Liquid Capsule Filling Sealing Machine is a game-changer for the industry. Its cutting-edge technology allows for precise and efficient filling and sealing of liquid capsules, streamlining the production process. Here are some key features and benefits of the LCFS 300:

1. Advanced Filling Mechanism: The LCFS 300 is equipped with a high-speed filling mechanism that ensures accurate dosing and minimizes wastage. Its innovative design allows for the insertion of a smaller capsule within a larger one, creating the unique capsule-in-capsule format.

2. Sealing Perfection: With its state-of-the-art sealing technology, the LCFS 300 ensures airtight and leak-proof capsules. This eliminates the risk of contamination and ensures product integrity.

3. Speed and Efficiency: The LCFS 300 operates at an impressive speed, significantly reducing production time. Its automated processes minimize the need for manual intervention, increasing productivity and reducing labor costs.

4. Versatility and Adaptability: The LCFS 300 is designed to handle a wide range of liquid formulations, accommodating various viscosities and formulations. This flexibility makes it suitable for both pharmaceutical and nutraceutical manufacturers.

Section 3: Enhancing the Capsule-in-Capsule Process

The LCFS 300 takes the capsule-in-capsule format to new heights. By incorporating a smaller capsule within a larger one, manufacturers can achieve multiple benefits:

1. Controlled Release: The capsule-in-capsule format allows for controlled release of active ingredients, ensuring optimal absorption and bioavailability. This is particularly beneficial for time-released medications and nutraceutical formulations.

2. Increased Stability: By encapsulating sensitive ingredients within a secondary capsule, manufacturers can enhance stability and protect against degradation caused by external factors such as light, moisture, and air.

3. Customization and Differentiation: The capsule-in-capsule format offers a unique and visually appealing product presentation, setting brands apart from their competitors. This can be a valuable marketing tool in today's competitive market.

Conclusion:

The LCFS 300 Liquid Capsule Filling Sealing Machine is a game-changer for the pharmaceutical and nutraceutical industry. Its advanced technology, speed, and precision in filling and sealing liquid capsules make it an indispensable asset for manufacturers. The capsule-in-capsule format, made possible by the LCFS 300, opens up new possibilities for controlled release, increased stability, and product differentiation. Stay ahead of the competition with the LCFS 300 and revolutionize your liquid capsule production.

Check out our website for the best coil packing solutions from a leading manufacturer in the industry. Filling Packing Machine

"Efficient and Precise Liquid Capsule Filling and Sealing Machine for Optimal Product Packaging"