Title: Food Packing Machine Price, Types of Meal Tray Sealer Machines | Industrial Tray Sealing Overview

Description:

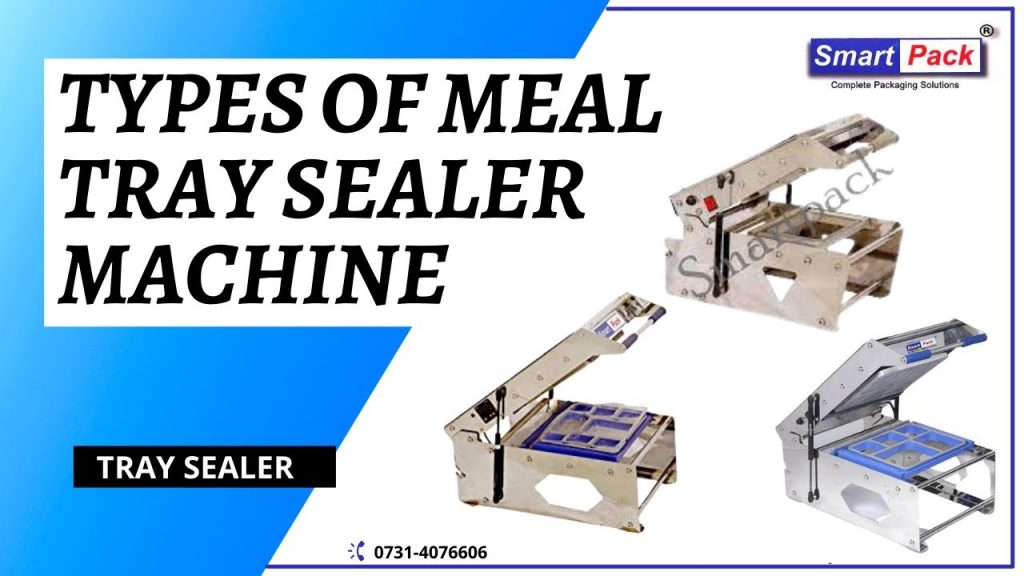

In this informative video, we present an in-depth exploration of the Food Packing Machine Price and the various types of Meal Tray Sealer Machines. The Tray Sealing Machine is an essential tool used in industrial settings to meet the packaging needs efficiently.

Introduction:

Welcome to our comprehensive video guide on Food Packing Machine Prices and the different types of Meal Tray Sealer Machines available in the market. We aim to provide you with a detailed overview of these machines, their functionalities, and their significance in the food packaging industry.

Video Content:

1. Types of Meal Tray Sealer Machines:

- Automatic Meal Tray Sealers: Discover the advantages and operation steps of automated tray sealing machines. These advanced systems offer high-speed performance, ensuring optimal productivity.

- Manual Meal Tray Sealers: Explore the features and benefits of manual tray sealers, which provide a cost-effective solution for smaller-scale packaging needs.

2. Industrial Tray Sealing Overview:

- Key Functions: Learn about the primary functions of tray sealing machines, including sealing, film application, and cutting. Discover how these machines ensure the freshness and quality of packaged food products.

- Versatile Applications: Gain insights into the diverse range of food products that can be efficiently packaged using tray sealing machines, such as ready-to-eat meals, snacks, desserts, and more.

- Efficiency and Cost-Effectiveness: Understand how tray sealing machines contribute to increased efficiency and reduced labor costs in food packaging operations.

Call to Action:

If you found this video helpful, please consider liking, subscribing, and sharing it with others who may benefit from this valuable information. Stay updated with our channel for more informative videos on industrial machinery and food packaging solutions.

Additional Tags and Keywords:

Food Packing Machine, Meal Tray Sealer Machine, Tray Sealing Machine, Industrial Packaging, Food Packaging, Tray Sealing Overview, Packaging Solutions, Automatic Meal Tray Sealer, Manual Meal Tray Sealer, Efficiency in Packaging, Cost-Effective Packaging, Food Industry, Packaging Equipment.

Hashtags:

#FoodPackingMachine #MealTraySealerMachine #TraySealingOverview #IndustrialPackaging #FoodPackaging #PackagingSolutions #AutomaticSealer #ManualSealer #EfficiencyinPackaging #CostEffectivePackaging #FoodIndustry #PackagingEquipment

Title: An Overview of Different Types of Meal Tray Sealer Machines

Introduction:

The food industry relies on efficient packaging solutions to maintain the quality and freshness of meals. Meal tray sealer machines play a crucial role in this process by securely sealing trays, ensuring food safety, and extending shelf life. In this article, we will explore various types of meal tray sealer machines commonly used in the industry.

1. Manual Meal Tray Sealer:

Ideal for small-scale operations, manual meal tray sealers require human intervention during the sealing process. These machines are easy to operate, cost-effective, and suitable for low-volume production. Manual meal tray sealers are often used in catering services, food trucks, or small restaurants.

2. Semi-Automatic Meal Tray Sealer:

Semi-automatic meal tray sealers combine manual and automated processes. The trays are manually loaded into the machine, while the sealing is done automatically. These machines are popular among medium-sized food manufacturers or establishments that require higher production rates than what a manual sealer can offer.

3. Automatic Meal Tray Sealer:

Designed for high-volume production, automatic meal tray sealers are capable of handling a large number of trays per minute. These machines have a fully automated process, from tray loading to sealing, minimizing human intervention. Automatic sealers are commonly used in large food production facilities or industrial settings.

4. Rotary Meal Tray Sealer:

Rotary meal tray sealers are known for their efficiency and speed. They have a rotating system that allows for continuous production, reducing downtime. These machines are often used in fast-paced food production lines to meet high demand and maintain productivity.

5. Vacuum Meal Tray Sealer:

Vacuum meal tray sealers remove air from the tray before sealing, prolonging the shelf life of the food. By minimizing oxygen exposure, vacuum sealers help prevent spoilage and maintain product quality. This type of sealer is commonly used for perishable items or in food packaging facilities that require extended shelf life.

6. Gas Flush Meal Tray Sealer:

Gas flush meal tray sealers inject a protective gas, such as nitrogen or carbon dioxide, into the tray before sealing. This gas helps maintain the freshness and appearance of the food, making it an ideal choice for ready-to-eat meals or pre-packaged salads. Gas flush sealers are commonly used in large-scale food production facilities.

Conclusion:

Meal tray sealer machines come in various types to cater to different production needs in the food industry. Whether it's a small-scale operation or a large-scale production facility, choosing the right type of sealer is essential to ensure food safety, quality, and extended shelf life. By understanding the different types of meal tray sealer machines available, businesses can make informed decisions that align with their specific requirements.Food Packing Machine

#TYPES #MEAL #TRAY #SEALER #MACHINE